A post-press finishing counting device for an ink-wash printing machine

A technology of counting device and printing machine, which is applied in stacking receiving device, thin material handling, transportation and packaging, etc., can solve the problems of chaotic stacking of corrugated boxes, occupying a lot of space, and occupying a large turnover space, so as to achieve thorough separation and cleaning. thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

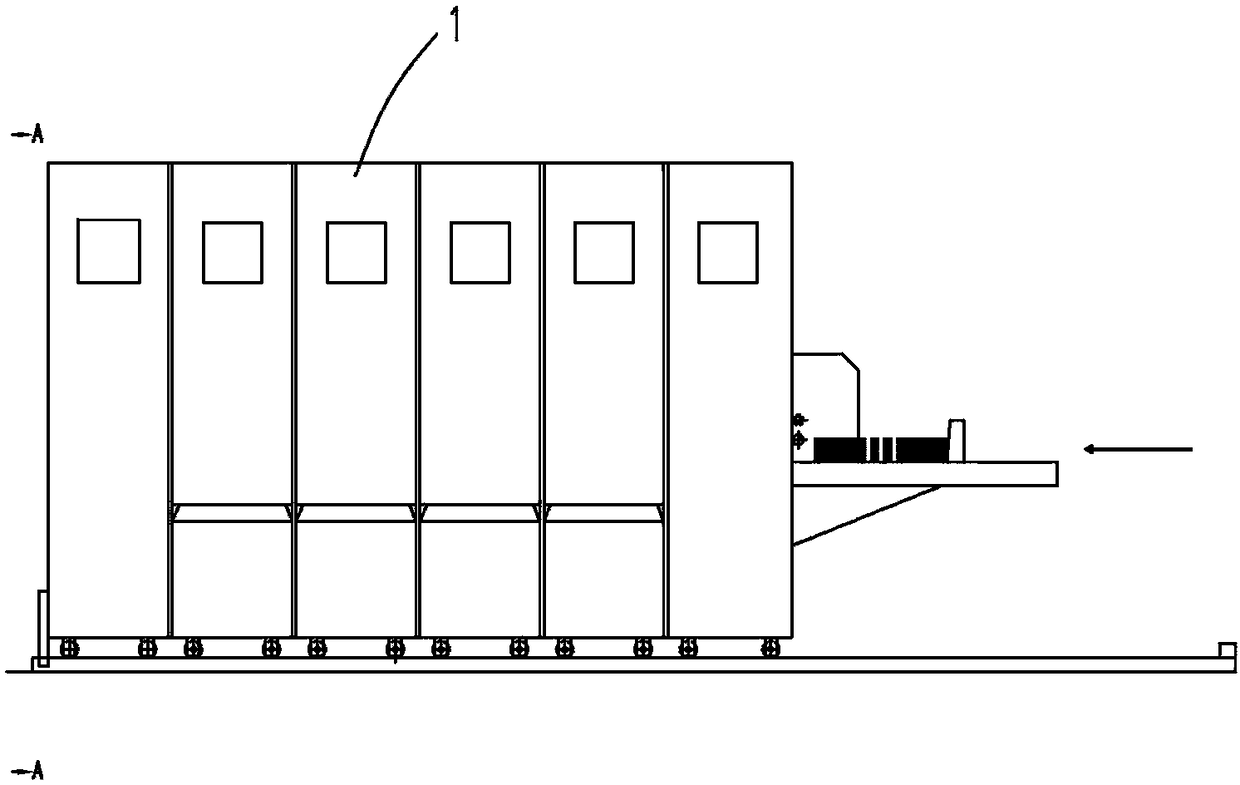

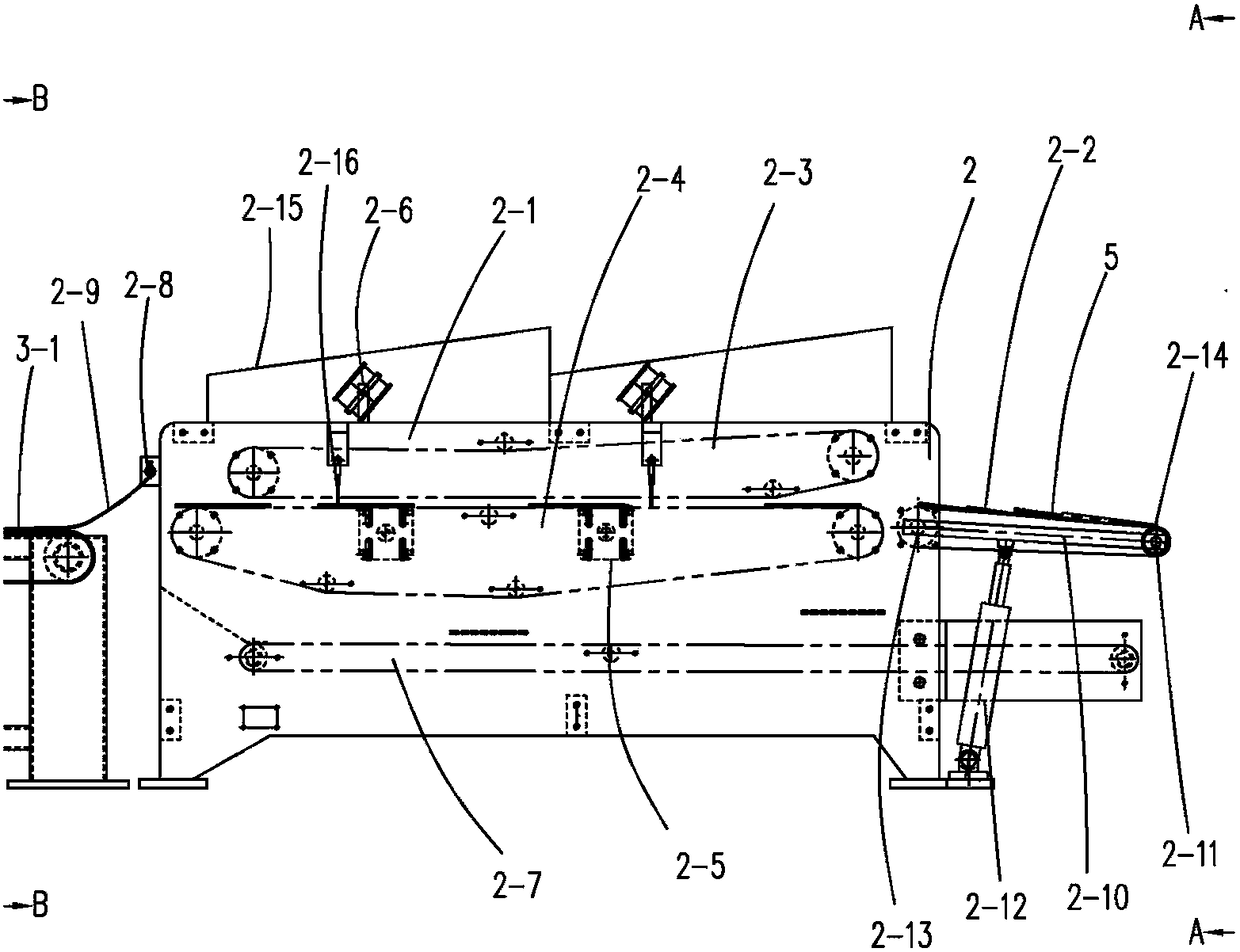

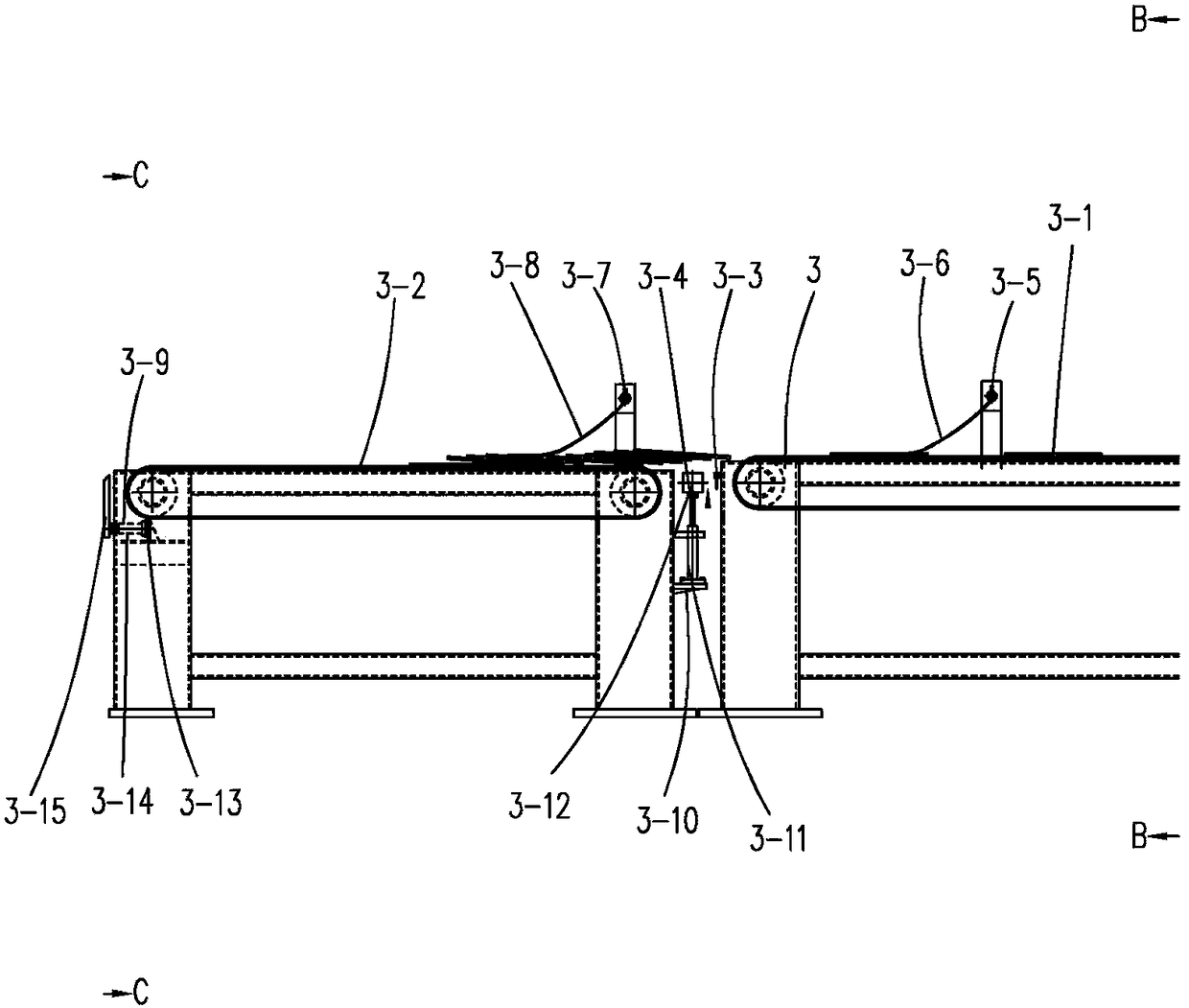

[0034] Depend on Figure 1 to Figure 9 Given, the present invention includes an ink printing die-cutting machine 1, a double-oscillating waste cleaning machine 2, a separation and counting device 3, an alignment buffer device 4, an ink printing die-cutting machine 1, a double-oscillating waste cleaning machine 2, and a separation and counting device The device 3 and the buffering device 4 are arranged sequentially, and it is characterized in that,

[0035] The double-oscillating waste cleaning machine includes a frame 2-1, a carton board transfer mechanism 2-2, an upper round belt conveyor 2-3, a lower round belt conveyor 2-4, and a fan 2-6. , oscillator 2-5, the first platen shaft 2-8, the carton plate transmission mechanism 2-2 is installed on the front side of the frame 2-1 and the front end height of the carton plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com