Screw-reversible directional arrangement device

A technology of directional arrangement and screws, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of delaying time, affecting production, easy to fall, etc., and achieve the effect of reducing workload and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

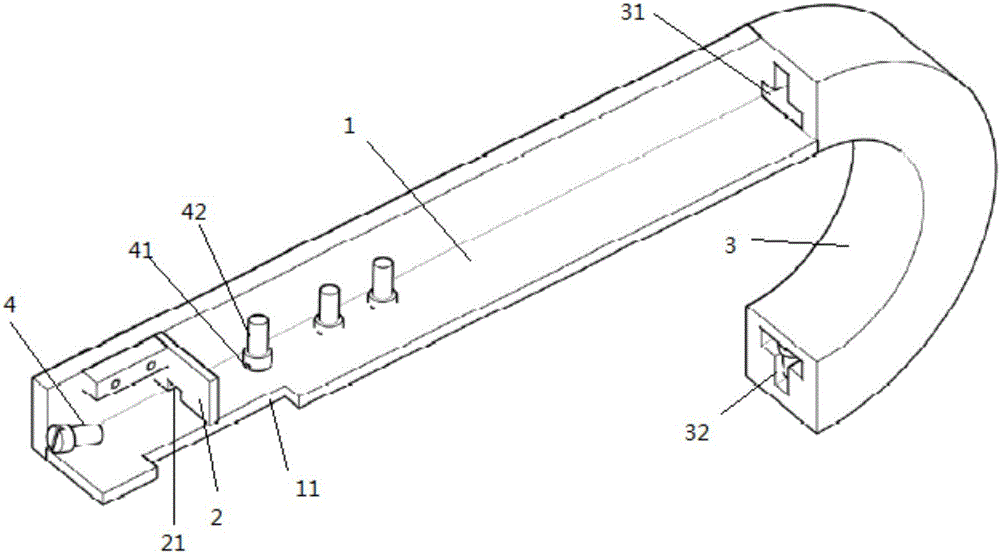

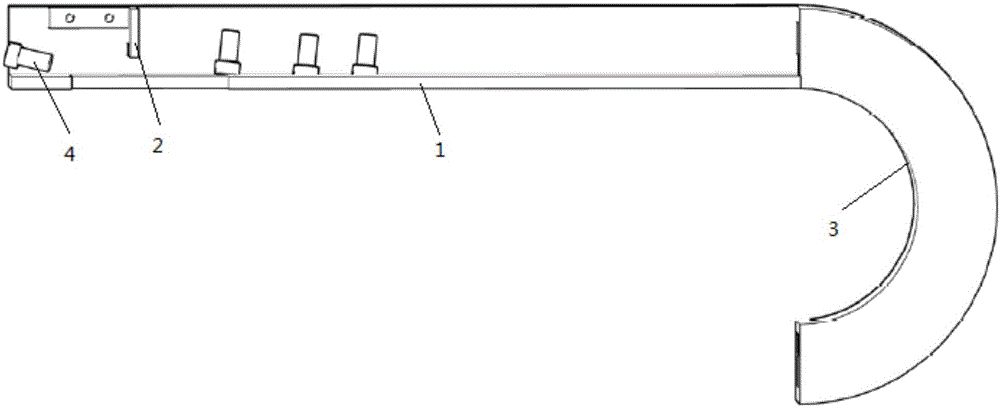

[0028] to combine Figure 1-Figure 2 , this embodiment describes in detail the screw reversible orientation arrangement device of the present invention, as figure 1 Shown is a schematic diagram of its structure, which includes: a guide rail 1, a material retaining plate 2 and a reversing slide chute 3, the material retaining plate 2 is arranged on the guide rail 1, and the reversing slide chute 3 is arranged at the discharge end of the guide rail 1; Guide rail 1 is used to make screw 4 slide with it, and one end of screw 4 is big head 41, and the other end of screw 4 is small head 42; The screw 4 with the small h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com