Backdoor assembling aid

A technology for back doors and auxiliary equipment, applied in transportation, packaging, motor vehicles, etc., can solve the problems of heavy manual adjustment workload, laborious operation, large space, etc., to reduce the amount of manual adjustment, reduce labor intensity, and easy operation flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

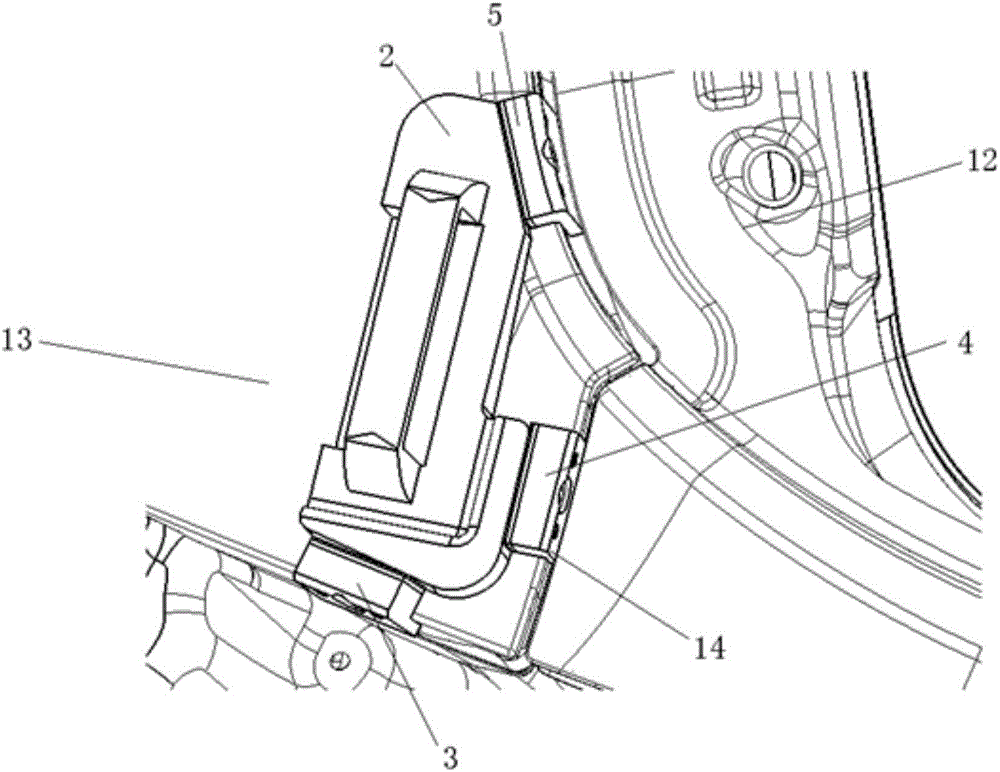

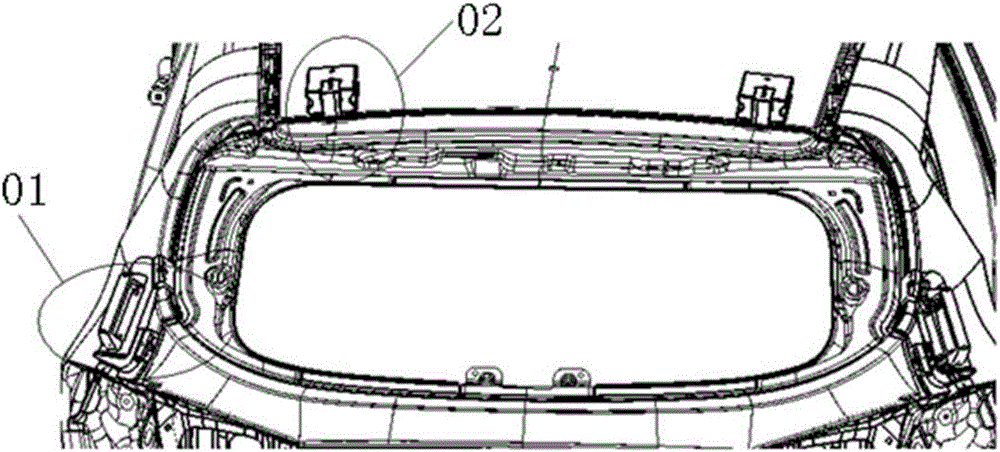

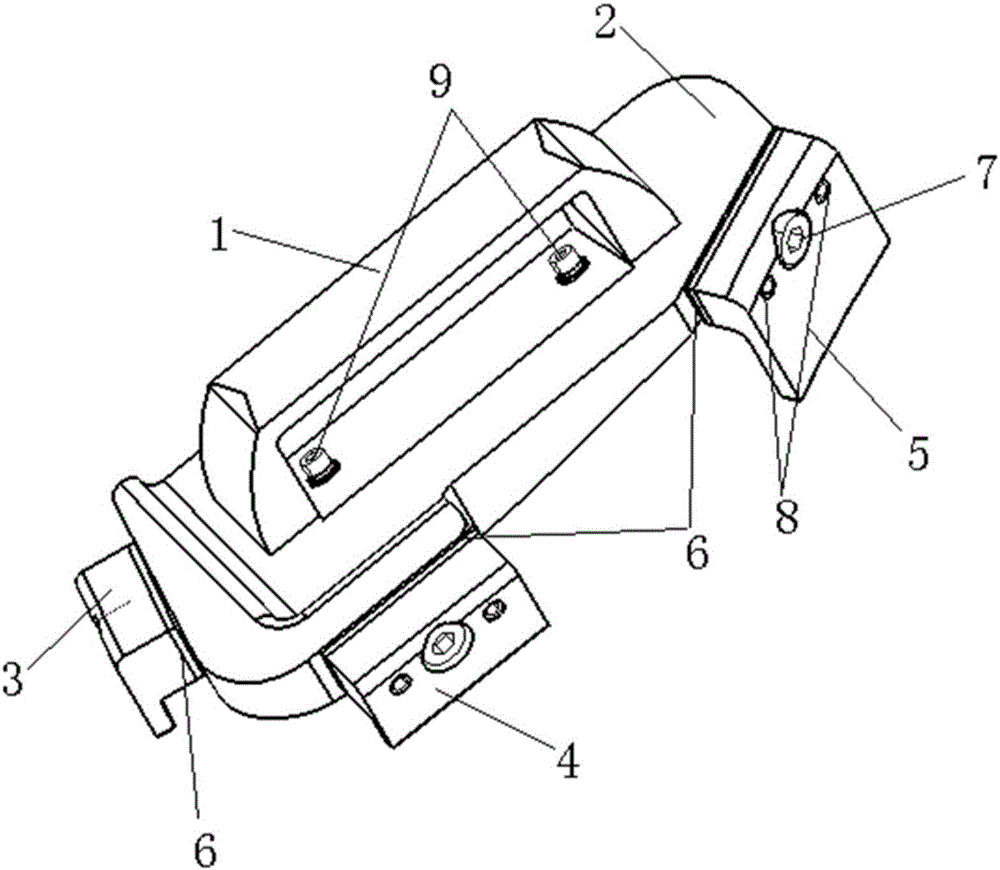

[0033] This application provides a back door assembly aid, such as Figure 1 to Figure 8 As shown, it includes two first auxiliary assembly modules 01 and two second auxiliary assembly modules 02.

[0034] The two first auxiliary assembly modules are used symmetrically on the axial centerline of the vehicle; the two second auxiliary assembly modules are used symmetrically on the axial centerline of the vehicle; the corresponding clamping blocks are extended to the side wall 13 based on the appearance characteristics of the vehicle body And between the back door 12 and the matching gap between the top cover 22 and the back door 12, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com