Distributed electric drive control system and method based on perpendicular load real-time estimation

A vertical load and control system technology, applied in electric vehicles, control drives, control devices, etc., can solve problems such as the inability to achieve better driving force distribution control and drive anti-skid, and achieve the goal of improving handling stability and driving safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

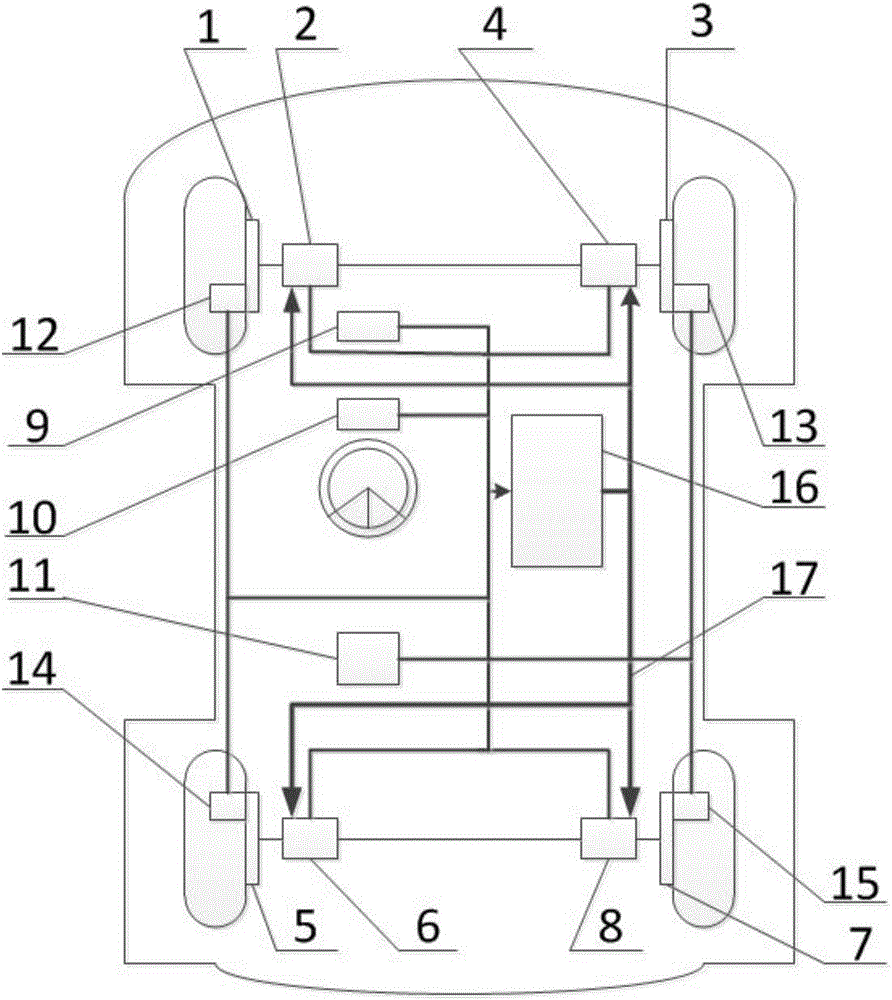

[0030] Such as figure 1 As shown, a distributed electric drive control system based on real-time estimation of vertical loads, including left front hub motor 1, left front hub motor controller 2, right front hub motor 3, right front hub motor controller 4, left rear hub motor 5, left Rear hub motor controller 6, right rear hub motor 7, right rear hub motor controller 8, electronic accelerator pedal 9, steering wheel angle sensor 10, acceleration sensor 11, left front tire pressure sensor 12, right front tire pressure sensor 13, left rear tire Pressure sensor 14, right rear tire pressure sensor 15, distributed drive controller 16, communication line 17. The distributed drive controller 16 communicates with the electronic accelerator pedal 9, the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com