Method and device for improving biomass compression molding rate

A technology of compression molding and biomass, which is applied in the direction of material molding presses, presses, mold extrusion granulation, etc., which can solve the problems of high energy consumption, poor molding effect, and low production efficiency of biomass compression molding. Achieve the effect of improving the quality and effect of bonding molding, avoiding bad molding effect, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

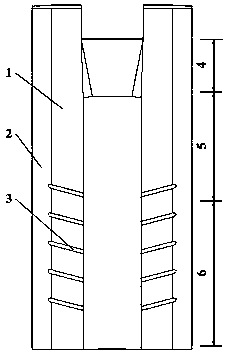

[0035] Such as figure 1 shown.

[0036] A method for improving biomass compression molding rate, comprising the following steps:

[0037] Firstly, an exhaust passage 2 is set between the molding die 1 and the body of the main molding machine. The main molding machine adopts a hot pressing molding process, and the molding temperature range is 100-200°C. The mouth is connected, and the biomass raw materials (such as wheat straw, rice straw, corn straw, rice husk, forage grass, etc.) of the feed port are heated by the heat of the exhaust channel 2. The moisture content of the biomass raw material ranges from 10% to 25%) for heating;

[0038] Secondly, the vent hole 2 is set on the cavity wall of the shape-preserving section 6 of the molding die 1, and the angle between the center line of the vent hole and the center line of the die hole is less than 90°, preferably greater than or equal to 45°, and less than 90° , the hole diameter is 2-5mm, the angles of the exhaust holes 2 c...

Embodiment 2

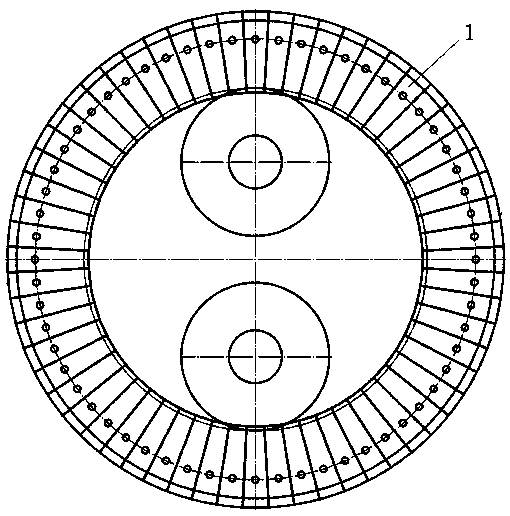

[0042] A device for improving the compression molding rate of biomass, which includes a molding die 1, and the installation form of the molding die 1 is as follows figure 2 As shown, a plurality of exhaust holes 3 are arranged on the cavity wall of the shape-retaining section 6 of the molding horizontal 1, and the exhaust holes 3 communicate with the exhaust channel 2, and the exhaust channel 2 is located outside the molding die 1 and Forming between the host body. The angle between the centerline of the vent hole 3 and the centerline of the die hole is greater than or equal to 45° and less than 90°, and the diameter of the hole is 2-5 mm. The angles between the central line of the vent hole 3 and the central line of the die hole are the same or different, and the apertures are the same or different.

[0043] According to the different processes of biomass compression molding, the die hole of the forming mold can be divided into three parts: pre-compressing section 4, formin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com