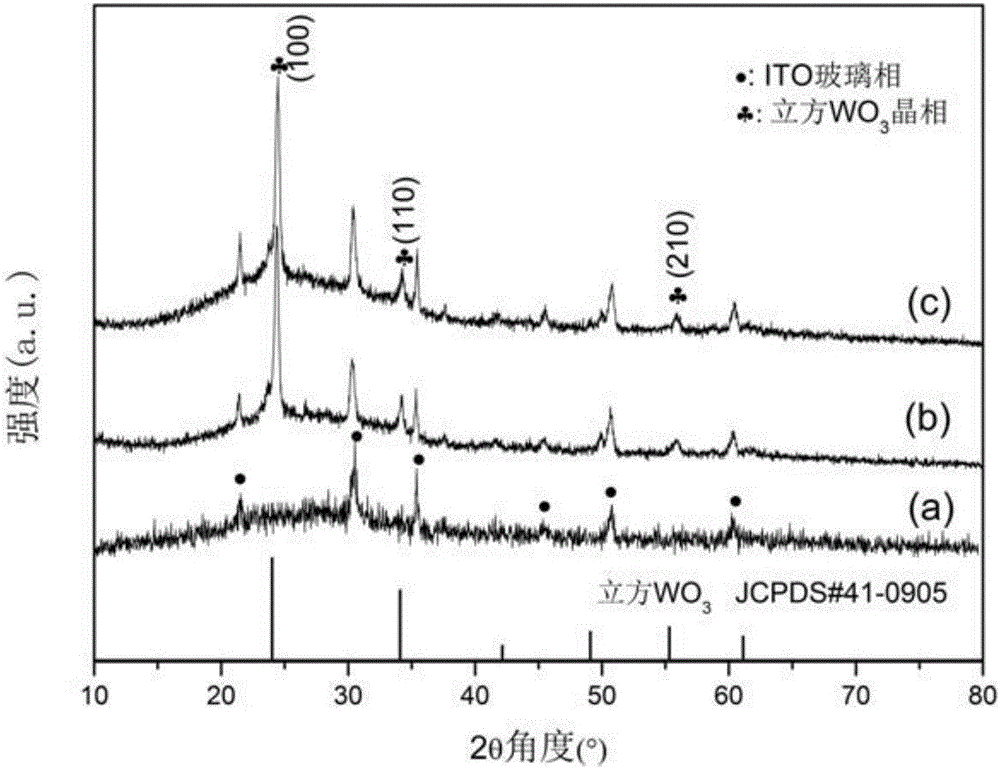

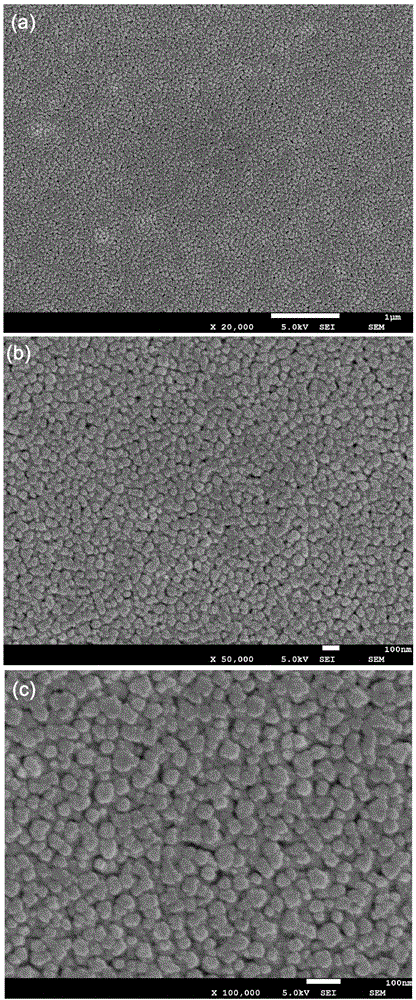

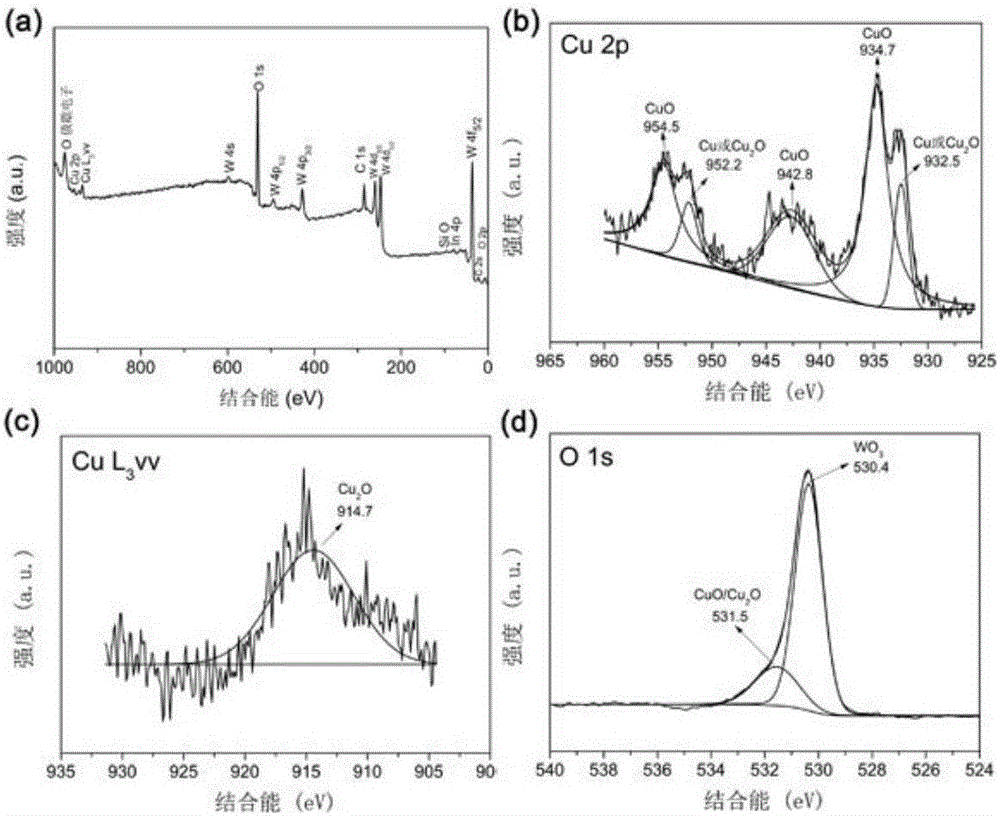

Preparation method of Cu2O/CuO/WO3 composite heterojunction thin film

A composite heterojunction and thin film technology, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of less research on ternary heterojunction thin films , poor reproducibility and uniformity, low cost, etc., to achieve the effect of being conducive to photo-generated charge transfer, improving photocatalytic activity, and simple film-forming equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a Cu 2 O / CuO / WO 3 A method for preparing a composite heterojunction thin film, comprising the following steps:

[0030] Step 1, prepare precursor sol

[0031] Weigh 2g of PVP with a molecular weight of 13000, and then measure 10ml of distilled water, then place the weighed PVP in a beaker filled with distilled water, place it on a constant temperature magnetic stirrer and continue stirring until the PVP is completely dissolved; then, add 0.5g The ammonium metatungstate was stirred again until the ammonium metatungstate was completely dissolved; then, 0.02 g of copper acetylacetonate was added, and the stirring was continued to completely dissolve it to obtain a precursor sol;

[0032] Step 2, spin coating

[0033] The prepared precursor sol was spin-coated on a 5cm*5cm ITO conductive glass through a homogenizer, and the set parameters were: speed 1 was 900r / min, time 1 was 8s, speed 2 was 2800r / min, time 2 was 50s, the number of spin coats is 2 layers, and then drie...

Embodiment 2

[0037] a Cu 2 O / CuO / WO 3 A method for preparing a composite heterojunction thin film, comprising the following steps:

[0038] Step 1, prepare precursor sol

[0039] Weigh 30g of PVP with a molecular weight of 40000, and then measure 100ml of distilled water, then place the weighed PVP in a beaker filled with distilled water, place it on a constant temperature magnetic stirrer and continue stirring until the PVP is completely dissolved; then, add 5g of PVP Ammonium metatungstate was stirred again until the ammonium metatungstate was completely dissolved; then, 0.2 g of copper acetylacetonate was added and stirred continuously to completely dissolve to obtain a precursor sol.

[0040] Step 2, spin coating

[0041] Spin-coat the prepared precursor sol on a 5cm*5cm ITO conductive glass through a homogenizer, and set the parameters as follows: speed 1 is 1200r / min, time 1 is 12s, speed 2 is 3200r / min, time 2 is 70s, the number of spin coats is 5 layers, and then dried at 120°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com