Variable multi-focus artificial lens

An intraocular lens, multi-focus technology, applied in the field of medical supplies, can solve the problems of limited moving distance, thick lens, low refractive index, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

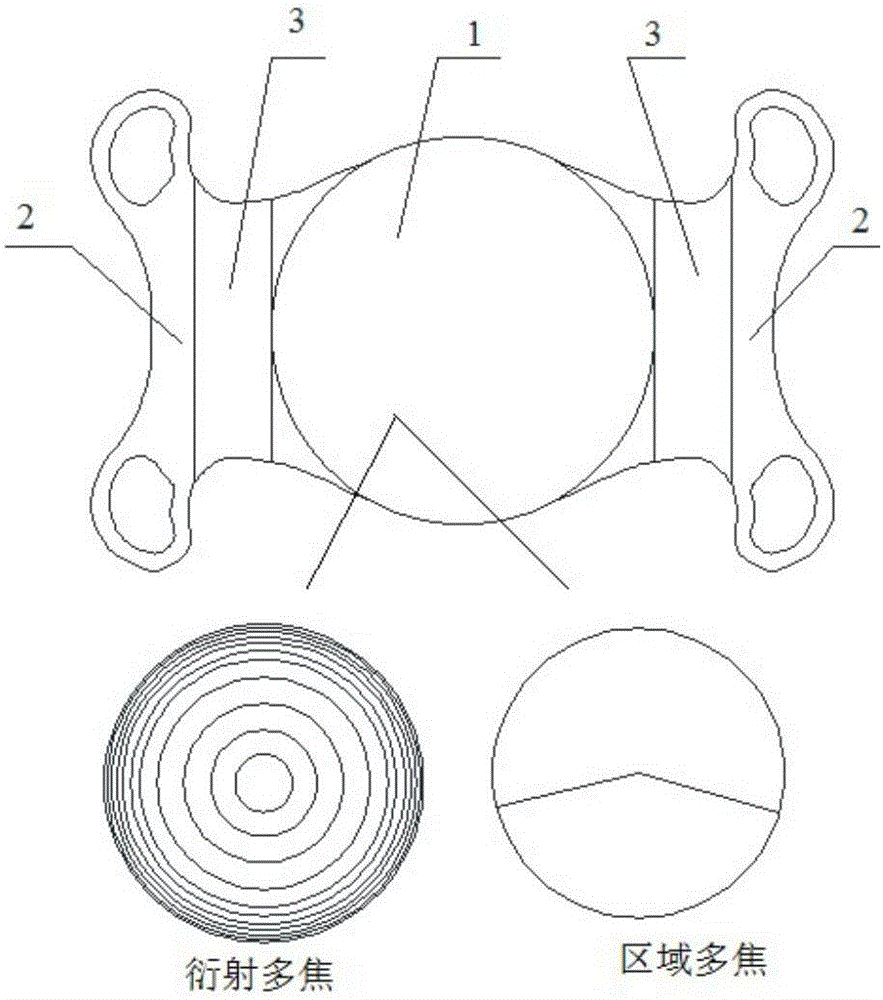

[0054] refer to Figure 1-7 , the variable trifocal intraocular lens is an assembled intraocular lens, the trifocals are 13.5D, 20D, and 23.5D respectively, and its preparation method is as follows:

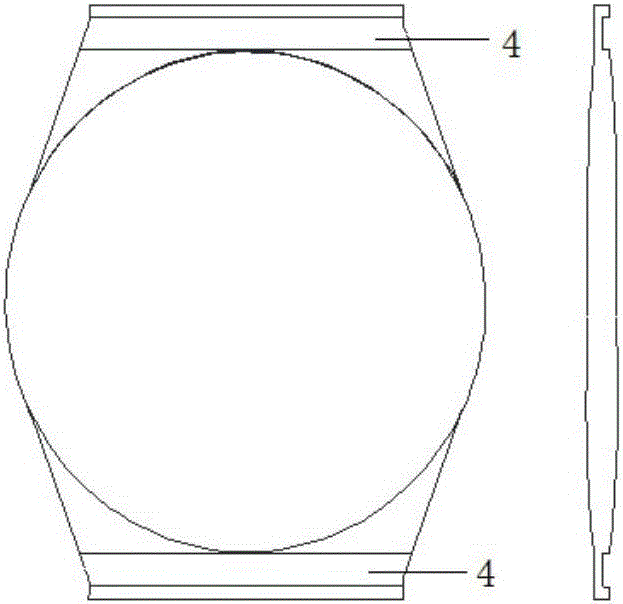

[0055] (1) First make an intraocular lens disc (13mm in diameter) containing a trifocal optical surface;

[0056] (2) Carve the disc made in step (1) into a single-piece lens, then cut it into an optical body and two haptics, and make the silicone connecting piece through compression molding;

[0057] (3) Coat the convex grooves of the two silicone connectors with medical glue and fill them at both ends of the optical body. The convex grooves at both ends of the optical body are inserted into the grooves of the silicone connectors. The groove coincides with the convex groove of the silicone connector, and then the convex groove at the other end of the two silicone connectors is filled in the groove of the two haptics, so that the overall assembly of the three parts is completed ...

Embodiment 2

[0063] refer to Figure 1-7 , the variable trifocal intraocular lens is an assembled intraocular lens, the trifocals are 10D, 20D, and 30D respectively, and its preparation method is as follows:

[0064] (1) First make an intraocular lens disc (13 mm in diameter) containing a trifocal optical surface,

[0065] (2) Carve the wafer made in step (1) into a one-piece lens through mechanical carving, then cut it into an optical body and two haptics, and make the silicone connector through compression molding;

[0066] (3) Coat the convex grooves of the two silicone connectors with medical strong glue, and fill them at both ends of the optical body. The groove coincides with the convex groove of the silicone connector, and then the convex groove at the other end of the two silicone connectors is filled in the groove of the two haptics, so that the overall assembly of the three parts is completed and finally implanted in the human eye in pouch;

[0067] The material of the optical...

Embodiment 3

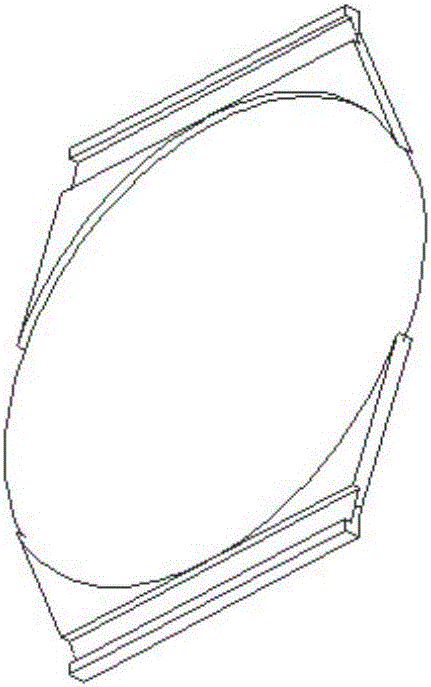

[0072] refer to Figure 8 , the variable trifocal intraocular lens is an assembled intraocular lens, the trifocals are 10D, 20D, and 30D respectively, and its preparation method is as follows:

[0073] (1) First make an intraocular lens disc (13 mm in diameter) containing a multi-focus optical surface;

[0074] (2) Carve the wafer made in step (1) into a one-piece lens through mechanical carving, then cut it into an optical body and two haptics, and make the silicone connector through compression molding;

[0075] (3) Coat the convex grooves at both ends of the optical body and the convex grooves of the two haptics with medical glue, and then insert them into the grooves at both ends of the silicone connector, so that the overall assembly of the three parts is completed, and finally implanted into the human body. in the pouch inside the eye;

[0076] The material of the optical body is hydrophobic polyacrylate, the diameter of the effective optical zone of the optical body i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com