Canned pear and preparation method thereof

A technology of canned pears and lye, applied in the field of canned pears and its preparation, can solve the problems of inability to achieve peeling effect, high production cost, and large loss of pears, so as to reduce pulp corrosion loss, labor cost, and raw material loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

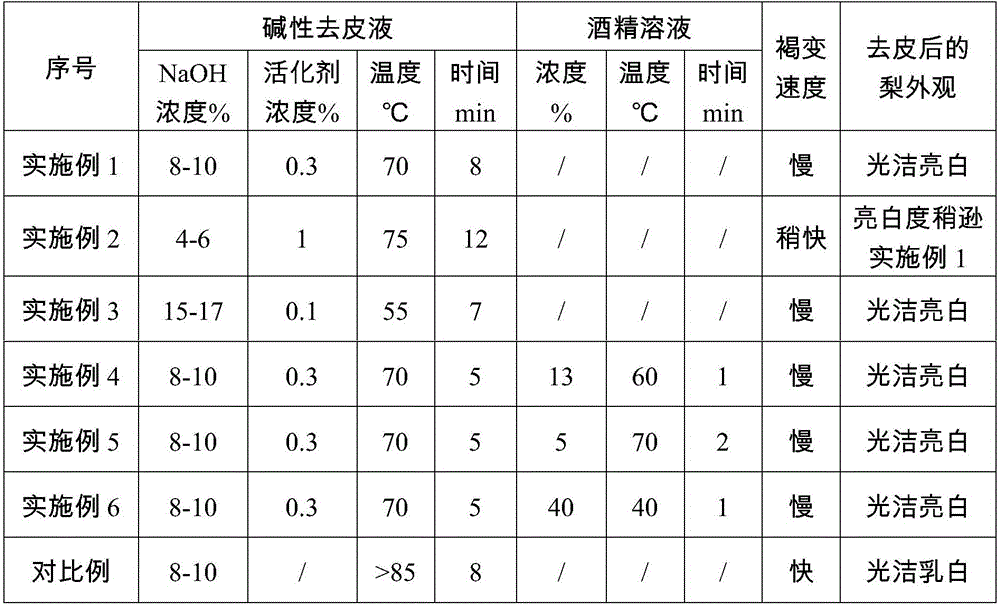

Embodiment 1

[0039] Alkaline preparation: prepare the lye whose concentration of sodium hydroxide is 8-10% (by weight), and add 0.3% (by weight of lye) of peeling activator to the lye to obtain alkaline peeling Skin fluid; in various embodiments of the present invention, the peeling activator includes a surfactant and an auxiliary agent with a weight ratio of 2:1; wherein, the surfactant includes lauric acid and Span- 20 (SP-20), the additive consists of citric acid, sodium carbonate and sodium chloride in a weight ratio of 2:2:1.

[0040] Alkaline corrosion: Soak the pears to be peeled in alkaline peeling solution for 8 minutes until the skin turns dark brown. The temperature of the alkaline peeling solution is controlled at about 70°C;

[0041] Friction peeling: The pears that have been etched by lye are quickly sent into the peeling drum with rubber rollers, so that the pears and pears and / or between the pears and the peeling drum rub against each other to remove the skin; at the same t...

Embodiment 2

[0046] Preparation of lye: preparation of lye with a sodium hydroxide concentration of 4-6% (by weight), and adding 1% (by weight) of peeling activator to the lye to obtain alkaline peeling solution ;

[0047] Alkaline erosion: Soak the pears to be peeled in alkaline peeling solution for 12 minutes until the skin turns dark brown, and control the temperature of the alkaline peeling solution at about 75°C;

[0048] Friction peeling: The pears that have been etched by lye are quickly sent into the peeling drum with rubber rollers, so that the pears and pears and / or between the pears and the peeling drum rub against each other to remove the skin; at the same time, use clean water Spray and rinse the pears to quickly wash off the lye on the surface;

[0049] Acid solution neutralization: transfer the pears obtained by friction peeling to the bubble cleaner, and use citric acid solution with a pH of 2.0 to neutralize the residual lye in the pears;

[0050] Color protection treatm...

Embodiment 3

[0052] Preparation of lye: preparation of lye with a sodium hydroxide concentration of 15-17% (by weight), and adding 0.1% (by weight) of peeling activator to the lye to obtain alkaline peeling solution ;

[0053] Alkaline corrosion: Soak the pears to be peeled in alkaline peeling solution for 7 minutes until the skin turns dark brown, and control the temperature of the alkaline peeling solution at about 55°C;

[0054] Friction peeling: The pears that have been etched by lye are quickly sent into the peeling drum with rubber rollers, so that the pears and pears and / or between the pears and the peeling drum rub against each other to remove the skin; at the same time, use clean water Spray and rinse the pears to quickly wash off the lye on the surface;

[0055] Acid solution neutralization: transfer the pears obtained by friction peeling to the bubble cleaner, and use citric acid solution with a pH of 2.0 to neutralize the residual lye in the pears;

[0056] Color protection t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com