Ultra-high temperature low-fat light cream for making cake products and production process thereof

A production process and cream technology, applied in dairy products, cream preparations, applications, etc., can solve problems such as the taste of cakes or the taste of milk, market application reduction, complex operations, etc., to reduce production costs, avoid waste, Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of ultra-high temperature low-fat cream used for making pastry products, according to the production capacity of one ton, the ingredients are as follows in Table 1:

[0035]

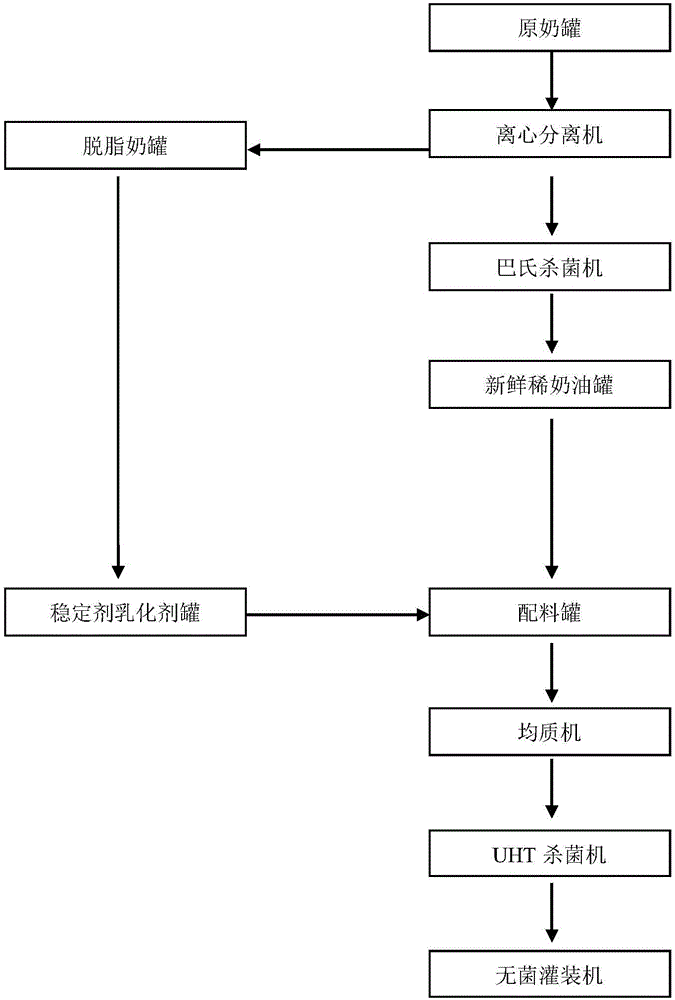

[0036] The production process of the prepared ultra-high temperature low-fat cream, such as figure 1 shown, including the following steps:

[0037] S1: Separation of fresh cream: Preheat the raw milk in the raw milk tank to 60-65°C, and centrifuge it into 40-46% fat cream and skimmed milk. The separated cream has a temperature of 85-95 ℃, temporarily store in the cream tank after sterilization for 16s, and temporarily store the separated skim milk in the skim milk tank;

[0038] S2: Dissolving stabilizer and emulsifier: pump skim milk heated to 60-65°C into the stabilizer and emulsifier tank, first put in liquid lecithin and Tween 80, then put in mixed powder additives, and stir for at least 15 minutes Dissolve completely and set aside;

[0039] S3: Mixing and homogenization: heat the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com