Gutter system for an IS machine

A technology for forming machines and glass bottles, which is applied in the field of groove systems and can solve problems such as the complexity of refitting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

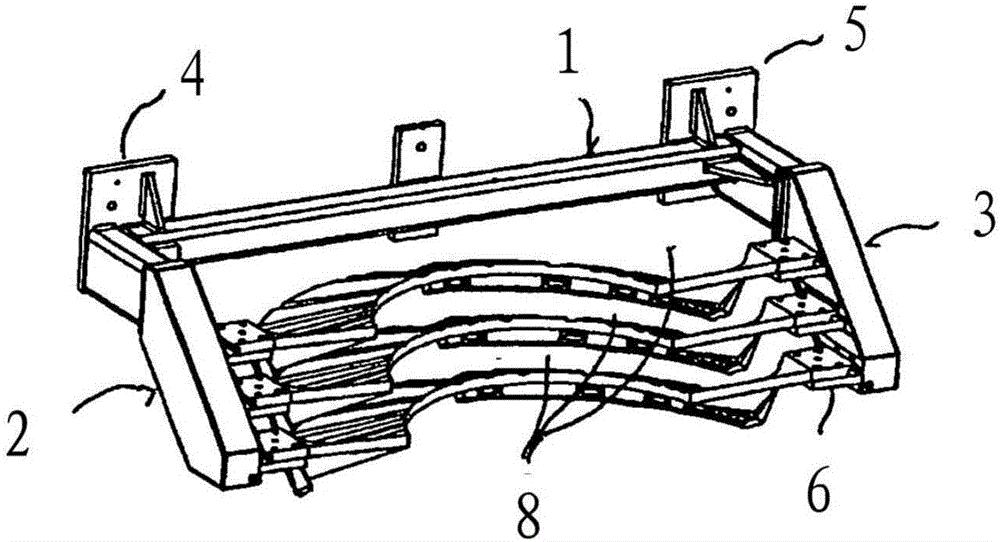

[0041] In order to illustrate the prior art, reference is first made to the accompanying drawings 1 to 5 , wherein a conventional structure defining an assembly for holding a guide plate as part of a groove system of a glass bottle forming machine is explained with reference to FIGS. 1 to 3 . These assemblies each consist of a base 1, on the two ends of which support arms 2, 3 are arranged, wherein the base 1 is provided for fixing to an The shown bucket beam is fastened to the machine frame of the glass forming machine.

[0042] The support arms 2 , 3 extend perpendicularly to the longitudinal extension of the base 1 in mutually parallel planes and are provided on their facing sides with holding plates 6 on which the mounting parts 7 each are formed. A guide plate 8 is placed below the middle arrangement structure. Depending on whether the assembly is used in single-, double- or triple-forming operation, one ( FIG. 3 ), two ( FIG. 2 ) or three are arranged on the support arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com