Cooling control system of liquid cooling server and control method thereof

A control system and server technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve problems such as repeated debugging, and achieve the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

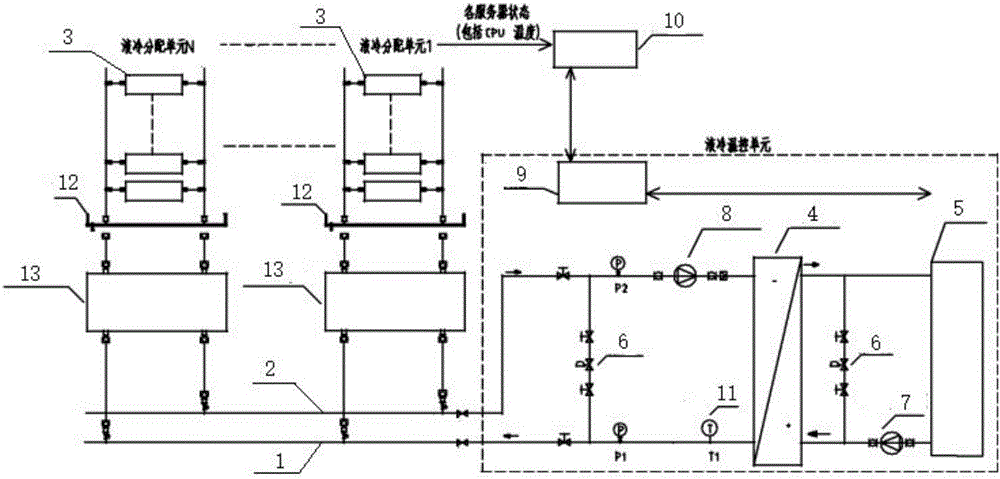

[0020] In order to allow those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with schematic diagrams.

[0021] Such as figure 1 , a heat dissipation control system for liquid-cooled servers, including a liquid supply pipeline 1, a number of liquid-cooled servers 3, and a liquid return pipeline 2 connected in sequence, and a plate heat exchanger is connected between the liquid supply pipeline 1 and the liquid return pipeline 2 4, cooling tower 5 and bypass valve 6, the external circulation frequency conversion pump 7 is arranged on the liquid supply pipeline, and the external circulation frequency conversion pump 7 is located between the plate heat exchanger 4 and the cooling tower 5, and the liquid return pipeline 2 is provided with There is an internal circulation frequency conversion pump 8, and the internal circulation frequency conversion pump 8 is located betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com