High-precision automatic power control circuit with temperature compensation

An automatic power control and temperature compensation technology, which is applied in the direction of amplification control, gain control, and improvement of amplifiers to reduce temperature/power supply voltage changes. It can solve the problems of power amplifier power consumption, output power drop, and large fluctuations. The effect of maintaining stable output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

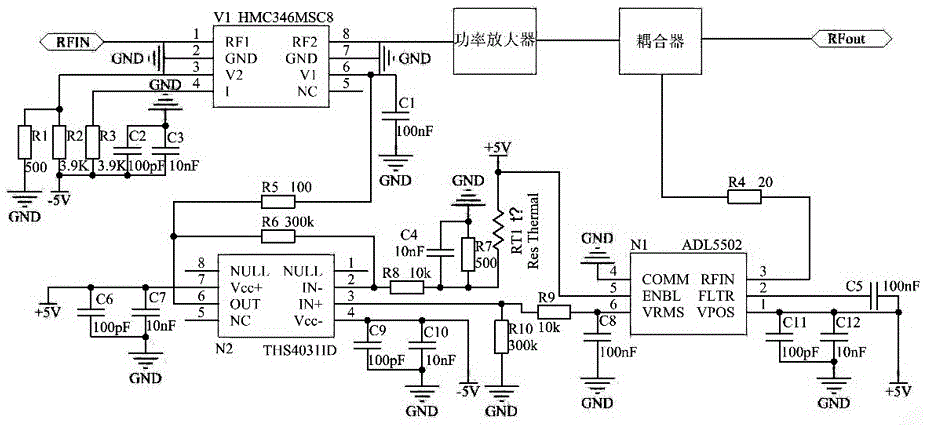

[0017] Such as figure 1 As shown, a high-precision automatic power control circuit with temperature compensation of the present invention includes a voltage-controlled attenuator, a power amplifier, a coupler, a high-precision RMS detector, a low-noise operational amplifier and a thermistor, and the voltage control The input terminal of the attenuator is used as the input terminal of the automatic power control circuit, the output terminal of the voltage control attenuator is connected with the input terminal of the power amplifier, the output terminal of the power amplifier is connected with the input terminal of the coupler, and one output terminal of the coupler is used as the output terminal of the automatic powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com