High-heat-dissipation semiconductor laser

A semiconductor and laser technology, applied in the field of lasers, can solve the problems of chip mounting components damage, low heat dissipation efficiency, etc., and achieve the effect of fast heat dissipation, high heat dissipation efficiency, and easy disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

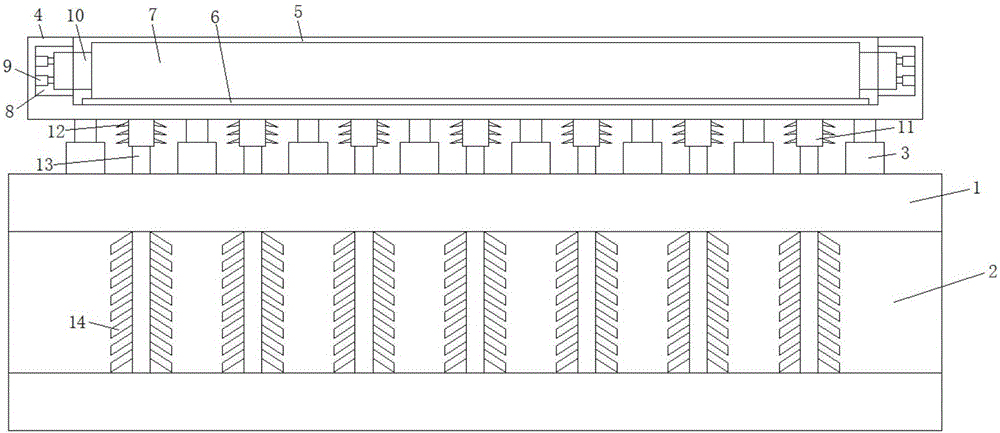

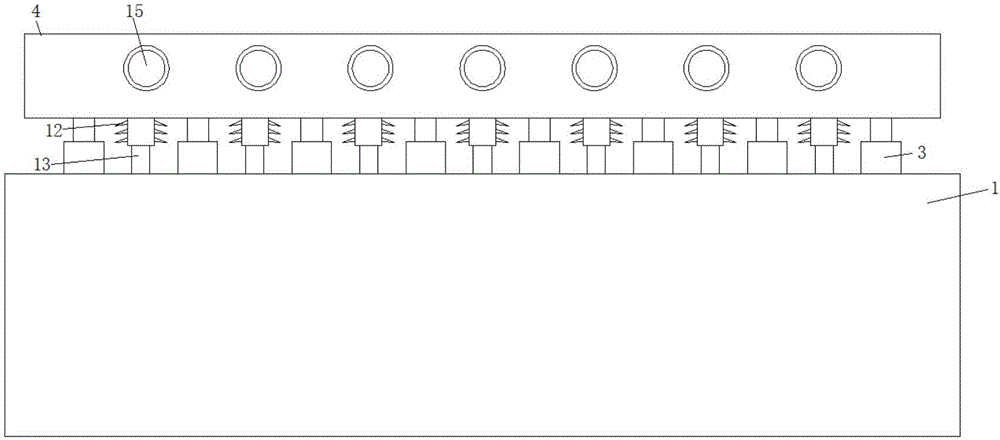

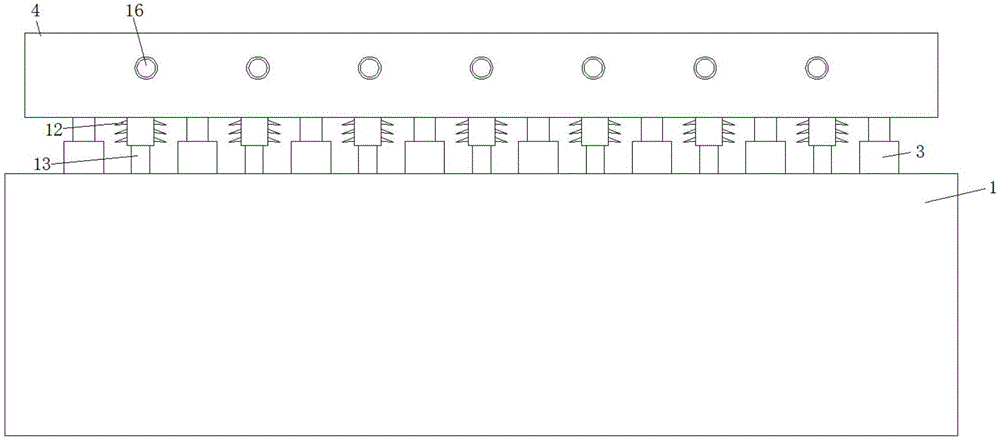

[0020] refer to Figure 1-4 , this embodiment proposes a high heat dissipation semiconductor laser, including a cooling base 1, a cooling passage 2 arranged along the length direction of the cooling base 1 is opened on the cooling base 1, and one end of a buffer mechanism 3 is welded on the top of the cooling base 1, The other end of the buffer mechanism 3 is welded with a placement seat 4, and the buffer mechanism 3 is used to buffer the vibration force transmitted between the cooling seat 1 and the placement seat 4. The top of the placement seat 4 is provided with a placement groove 5, and the bottom of the placement groove 5 A heat conduction plate 6 is fixedly installed on the inner wall, and a semiconductor laser chip mounting assembly 7 located in the placement groove 5 is placed on the heat conduction plate 6, and the inner walls of both sides of the placement groove 5 are provided with card slots 8, and the card slots 8 are far away from the card slots. 8 On the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com