Power battery cooling and heating integrated system and batteries

A power battery and integrated system technology, applied in the field of new energy vehicle batteries, can solve the problems of poor reliability, low heat utilization rate and short service life, and achieve good heating and cooling effect, high heat utilization rate and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

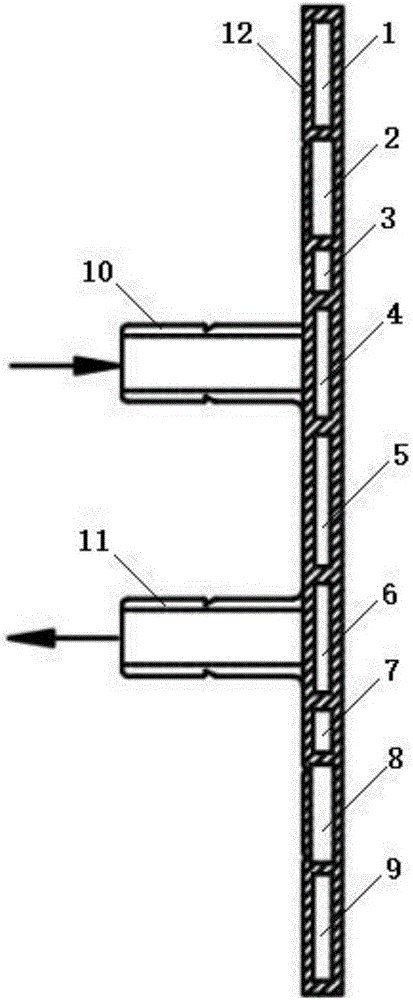

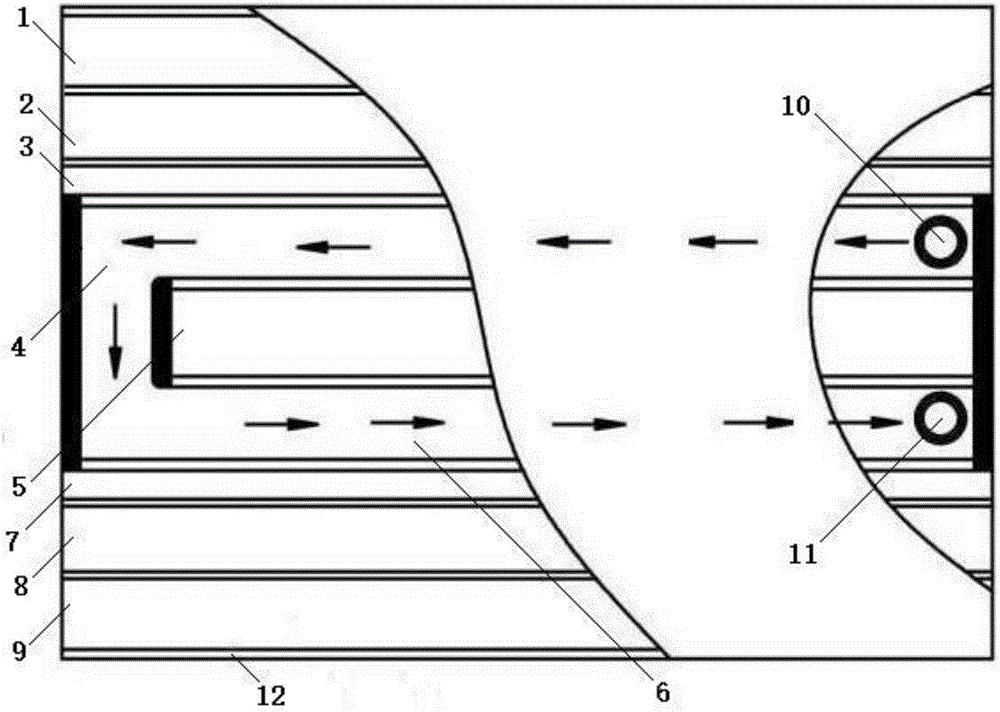

[0052] Such as Figure 1-3 , Figure 12A power battery cooling and heating integrated system is shown, including a coolant tank, a circulation pump and a radiator, the coolant tank is connected to the circulation pump, the circulation pump is connected to the radiator, one end of the battery pack heating and cooling integrated board is connected to the radiator, and the battery pack is heated The other end of the cooling integrated board is connected to the coolant tank; the heating and cooling integrated board of the battery pack includes a first PTC heating cavity 1, a second PTC heating cavity 2, a first heat insulation cavity 3, a first Coolant cavity 4, cavity 5, second coolant cavity 6, second heat insulation cavity 7, third PTC heating cavity 8, fourth PTC heating cavity 9, coolant inlet joint 10 and coolant outlet Connector 11, the first PTC heating cavity 1 is connected to the second PTC heating cavity 2, the second PTC heating cavity 2 is connected to the first heat...

Embodiment 2

[0054] Such as Figure 4 As shown, on the basis of Example 1, the first cooling liquid cavity 4 and the second cooling liquid cavity 6 are changed in parallel to set up dual channels. The dual-channel cooling liquid cavity doubles the refrigeration rate, and the channels are changed according to requirements. Quantity, adjust cooling power.

Embodiment 3

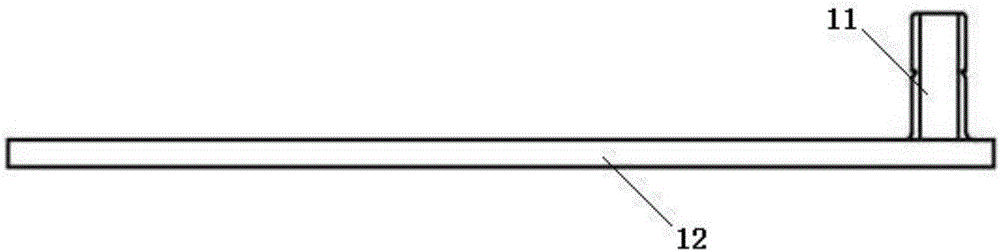

[0056] Such as Figure 5-7 As shown, a first PTC heating cavity 1, a second PTC heating cavity 2, a first heat insulation cavity 3, a first cooling liquid cavity 4, a cavity 5, and a second cooling liquid cavity are provided on the heat conducting substrate 12 6. The second heat insulation cavity 7, the third PTC heating cavity 8, the fourth PTC heating cavity 9, the coolant inlet connector 10 and the coolant outlet connector 11, the first PTC heating cavity 1 is connected to the second PTC heating cavity Body 2, the second PTC heating cavity 2 is connected to the first heat insulation cavity 3, the first heat insulation cavity 3 is connected to the first cooling liquid cavity 4, the first cooling liquid cavity 4 is connected to the cavity 5, and the cavity 5 is connected to the second Two cooling liquid chambers 6, the second cooling liquid chamber 6 is connected to the second heat insulating chamber 7, the second heat insulating chamber 7 is connected to the third PTC heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com