Preparation method of high-purity manganese monoxide

A manganese monoxide, high-purity technology, applied in the direction of manganese oxide/manganese hydroxide, electrochemical generators, electrical components, etc., can solve the problem that the impurity content is difficult to meet the requirements of high-purity manganese monoxide, and it is difficult to prepare high-purity mono Manganese oxide, high cost of use, etc., to achieve remarkable impurity removal effect, low raw material cost, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

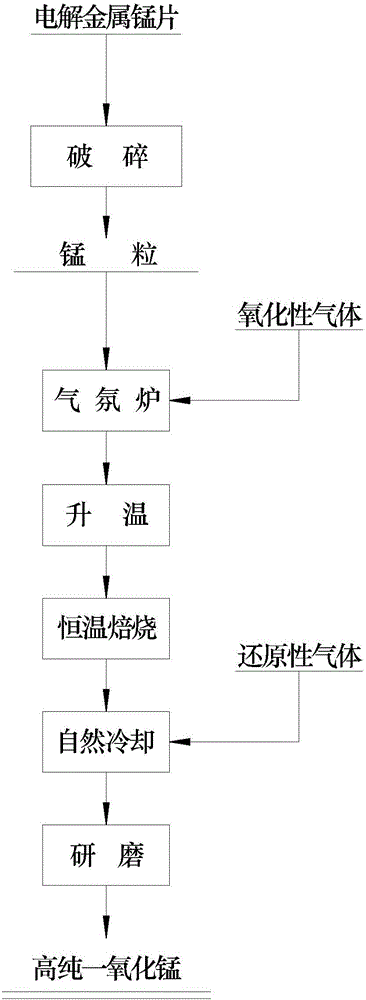

[0028] refer to figure 1 , a preparation method of high-purity manganese monoxide, comprising the following steps:

[0029] (1) Crushing electrolytic manganese metal flakes to obtain manganese particles, the particle size of which is less than 3 mm;

[0030] (2) placing the manganese particles in an atmosphere furnace;

[0031] (3) Pass oxidizing gas into the atmosphere furnace to drive out the air in the furnace;

[0032] (4) heating up the atmosphere furnace;

[0033] (5) When the temperature of the atmosphere furnace reaches 700°C to 750°C, enter the constant temperature roasting stage, and constant temperature roasting for a period of time;

[0034] (6) After the constant temperature roasting is completed, the reducing gas is introduced to cool the material naturally in the furnace;

[0035] (7) When the temperature of the material in the furnace is lowered, the material is taken out from the furnace;

[0036] (8) Grinding the material obtained in step (7) to obtain h...

Embodiment 1

[0038] The electrolytic manganese metal flakes are crushed to a particle size of 15 μm to obtain manganese particles; the obtained manganese particles are placed in a sagger, and then pushed into the atmosphere furnace with the sagger; carbon dioxide gas is introduced into the atmosphere furnace, Drive out the air in the atmosphere furnace, then raise the temperature of the atmosphere furnace at a rate of 5°C / min. When the temperature of the atmosphere furnace reaches 700° C. to 750° C., it enters the constant temperature roasting stage, and the constant temperature roasting is carried out for 2 hours. After the constant temperature roasting is finished, hydrogen gas is introduced, and the material is naturally cooled in the furnace, and the cooling time is 5 hours. When the temperature of the material in the furnace drops below 80°C, the sagger is taken out from the furnace, and then the material in the sagger is ground, and high-purity manganese monoxide can be obtained afte...

Embodiment 2

[0040] The electrolytic manganese metal flakes are crushed to a particle size of 14 μm to obtain manganese particles; the obtained manganese particles are placed in a sagger, and then pushed into the atmosphere furnace with the sagger; carbon dioxide gas is introduced into the atmosphere furnace, Drive out the air in the atmosphere furnace, then raise the temperature of the atmosphere furnace at a rate of 5°C / min. When the temperature of the atmosphere furnace reaches 700°C to 750°C, it enters the constant temperature roasting stage, and the constant temperature roasting is carried out for 2.5 hours. After the constant temperature roasting is finished, hydrogen gas is introduced, and the material is naturally cooled in the furnace, and the cooling time is 5.5 hours. When the temperature of the material in the furnace drops below 80°C, the sagger is taken out from the furnace, and then the material in the sagger is ground, and high-purity manganese monoxide can be obtained afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com