Flash memory structure and manufacturing method thereof

A manufacturing method and flash memory technology, which are applied to semiconductor devices, electrical components, circuits, etc., can solve problems such as reducing the performance of flash memory structures and adverse effects of gate structures, and achieve the effects of avoiding adverse effects, improving competitiveness, and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

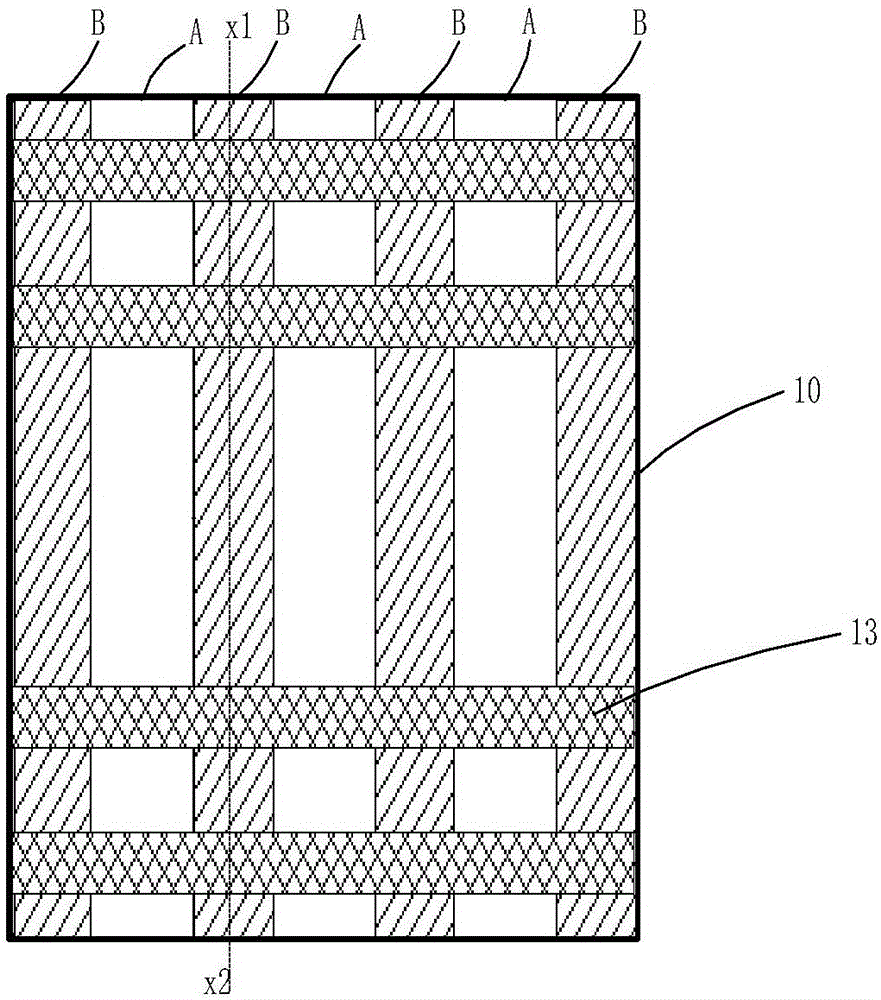

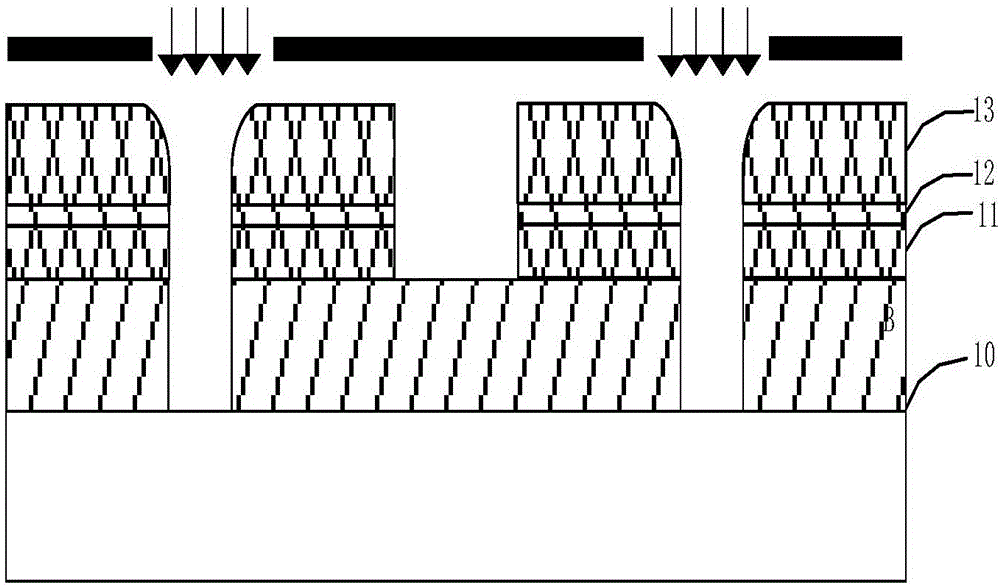

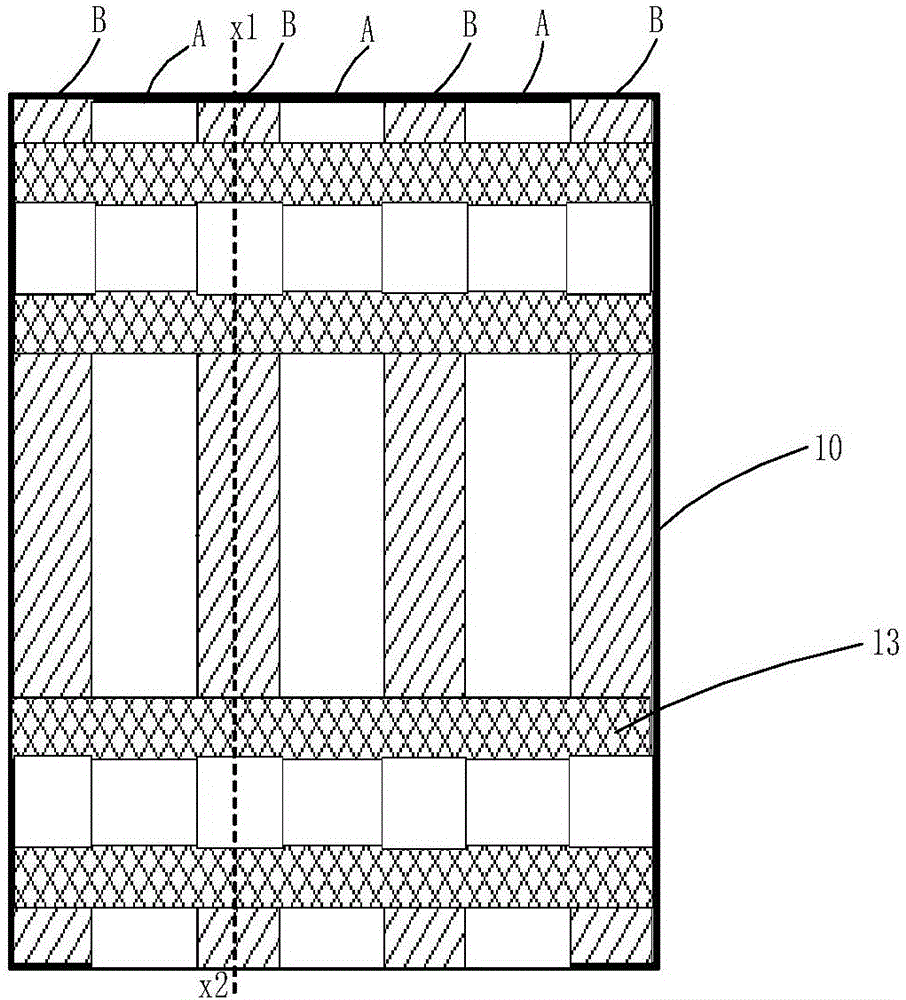

[0036] see Figure 1 to Figure 5 , is a top view and a cross-sectional structure diagram of a conventional flash memory structure manufacturing method well known to the inventor, and the flash memory structure manufacturing method includes: providing a substrate 10; forming an active region A and a shallow flash memory structure in the substrate 10 Trench isolation structure (STI) B, the active regions A are isolated by the shallow trench isolation structure B, and the shallow trench isolation structure B is filled with silicon dioxide; then, in the A gate structure is formed on the substrate 10, and the gate structure includes a floating gate layer 11 deposited on the substrate 10, a control gate layer 13 stacked on the floating gate layer 11, and a control gate layer on the control gate layer. 13 and the floating gate layer 11 is provided with an ONO (oxide-nitride-oxide) layer 12, such as figure 1 and 2 Shown; Next, adopt self-aligned source process (SAS) to form source 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com