Slow wave structure for high-power output of traveling wave tubes

A slow-wave structure and high-power technology, which is applied in the field of slow-wave structures, can solve problems such as hindering the development of helical traveling wave tubes, difficult processing, and complex structures, and achieve the goals of improving high-power output, easy processing, and expanding application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

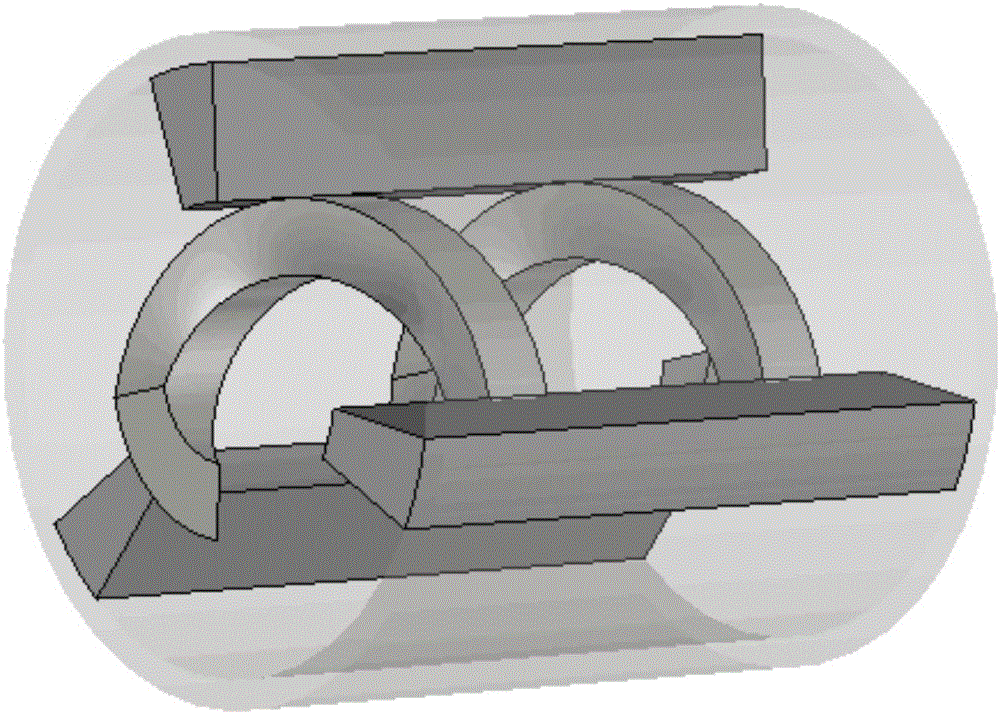

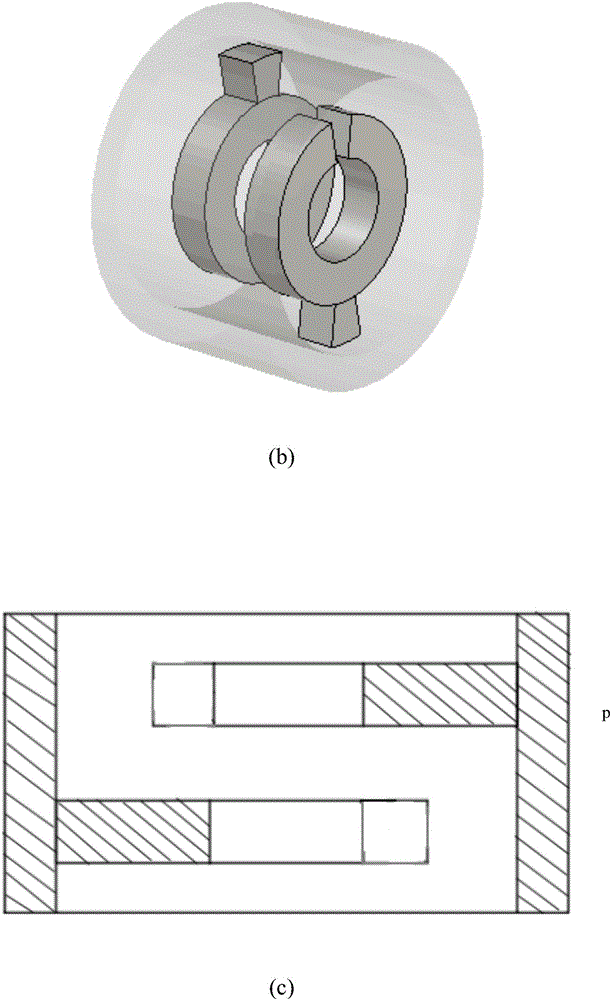

[0018] This embodiment is a design and application of a slow wave structure for high power output of a traveling wave tube in the Ka band.

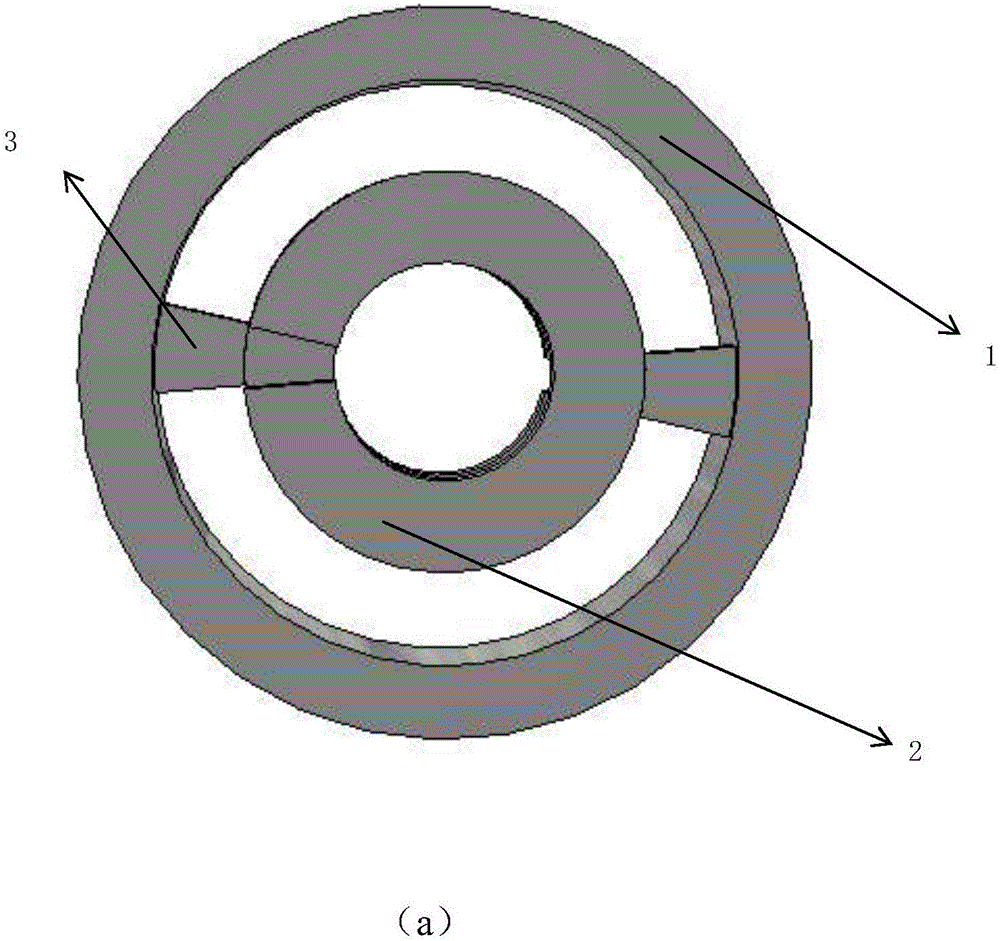

[0019] The slow wave structure described in this embodiment includes a cylindrical metal shell, a number of concentric open metal rings arranged in the shell, and a support structure for fixing the metal rings. The support structures of two adjacent metal rings are arranged symmetrically. on both sides.

[0020] The material of the supporting structure is metallic copper, its cross section is fan-shaped, the thickness is 0.25mm, and the angle is 18°. The inner diameter of the metal case is 0.80mm and the thickness is 0.20mm. The material of the concentric metal ring is metal copper, the inner diameter is 0.30mm, the thickness is 0.25mm, the distance between the two concentric metal rings is 0.30mm, the distance between the metal ring and the inner wall of the shell is 0.15mm, the metal ring The cross section of the ring opening is fan-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com