Compound-eye light homogenization system, optical engine and light source optimization device

A technology of optical system and compound eye, which is applied in the direction of photolithography exposure device, optics, microlithography exposure equipment, etc., can solve the problems of uneven energy distribution and high scrap rate of PCB boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

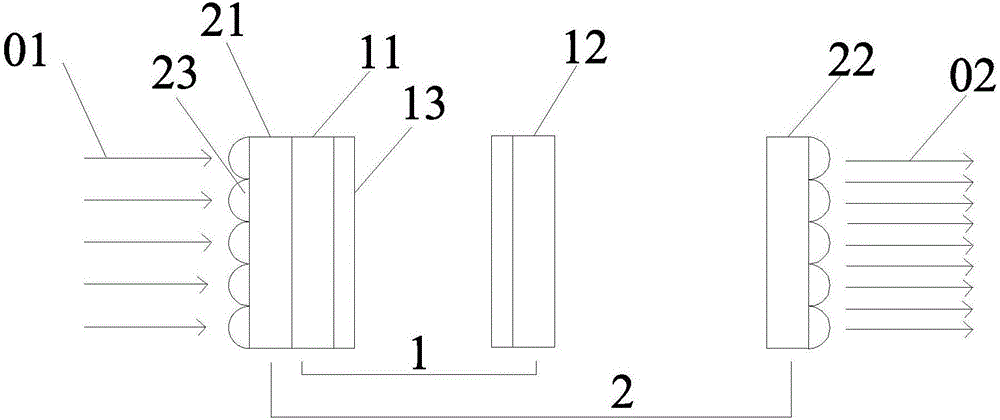

[0038] Such as figure 1 As shown, the compound eye homogenization system provided by the present invention includes a first lens group 1 and a second lens group 2, the first lens group 1 includes a second lens 11 and a third lens 12, and the second lens group 2 includes a first lens 21 and the fourth lens 22 .

[0039] The parallel incident light 01 passes through the first lens 21 , the second lens 11 , the third lens 12 and the fourth lens 22 in sequence.

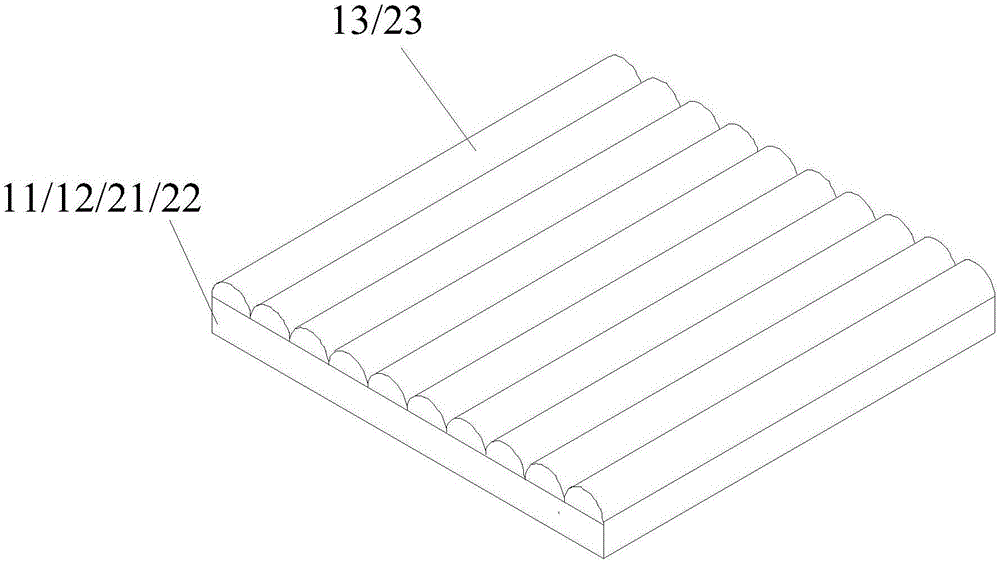

[0040] The light exit surface of the second eyeglass 11 and the light entrance surface of the third eyeglass 12 are all provided with a first fly-eye lens array 13; the light entrance surface of the first eyeglass 21 and the light exit surface of the fourth eyeglass 22 are all provided with a second fly eye lens array 23 ; the first fly-eye lens array 13 is perpendicular to the second fly-eye lens array 23 .

[0041] The focus of each small lens in the second fly-eye lens array 23 of the first eyeglass 21 coincides with...

Embodiment 2

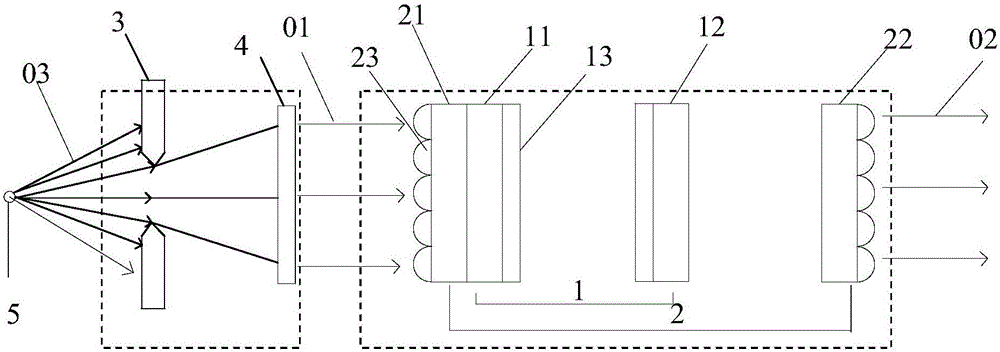

[0047] A DI device often contains more than two similar optical engines. The optical engine provides the source of light energy for DI. After the optical engine, it will go through a series of optical components. The differences between the optical engine itself and the subsequent optical devices will Causes the difference in energy reaching the exposure surface workbench. The optical engine can adjust this difference without affecting other performance of the device.

[0048] Most DI equipment adopts DMD imaging technology, limited to the size of the DMD frame, a DI equipment often needs multiple identical optical lens modules, which puts higher requirements on the optical engine contained in each lens module, requiring optical The engine performance is stable, and the energy is flexible and adjustable. Finally, it is ensured that the energy is uniform within the range of the DI imaging exposure area. The invention provides an optical engine with adjustable energy.

[0049...

Embodiment 3

[0062] A DI device often contains more than two similar light source optimization devices, which provide light energy sources for DI, and then pass through a series of optical components. The light source optimization device has its own differences. And the difference of subsequent optical devices will cause the difference of imaging quality reaching the exposure surface workbench. The light source optimization device can optimize this difference without affecting other performances of the equipment.

[0063] DI equipment involves DMD projection technology and optical imaging system. In optical imaging, the imaging quality of different wavelengths has certain differences. If the wavelength bandwidth of the light source is narrow enough, the imaging quality will be better, which has a better effect on the light source before reaching the imaging system. demanding. It is required that the wavelength of the light source is single and the performance is stable, so as to finally e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com