Manual developing concentrated solution kit for industrial X-ray film

A concentrated solution and X-ray technology, applied in the field of industrial X-ray film manual processing of concentrated solution medicine, can solve the problems of failing to meet the requirements of non-destructive testing, poor film wetting effect, low film photographic performance, etc. Reduces water absorption and improves clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation

[0024] In order to understand the present invention, the present invention will be further described below in conjunction with embodiment: following embodiment is illustrative, not limiting, can not limit protection scope of the present invention with following embodiment.

[0025] A kind of industrial X-ray film manual washing concentrated solution kit, which is composed of developing concentrated solution and fixing concentrated solution. The specific composition and content of the above ingredients are as follows:

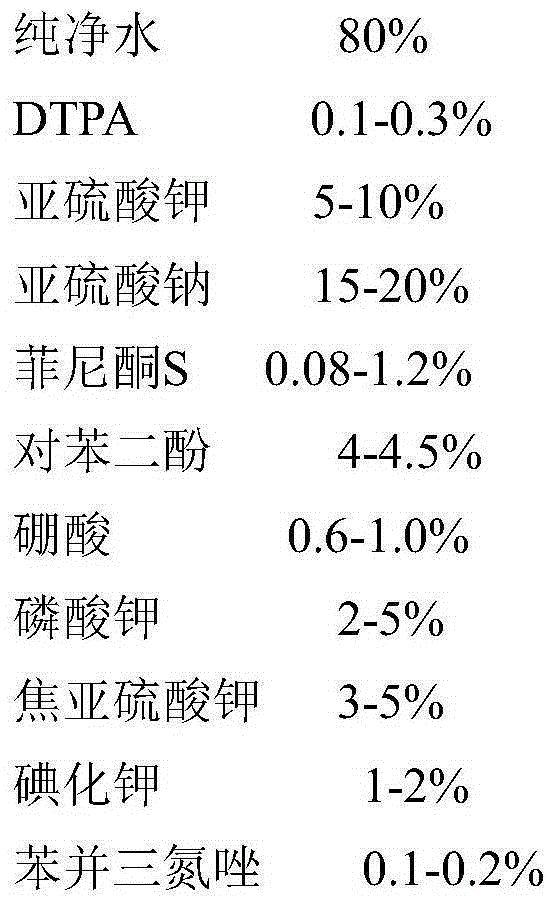

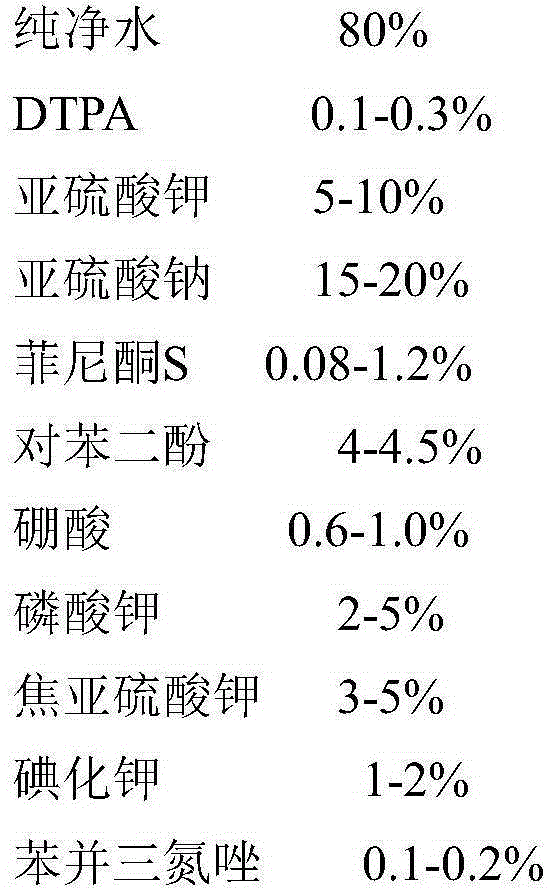

[0026] ⑴Development Concentrate

[0027]

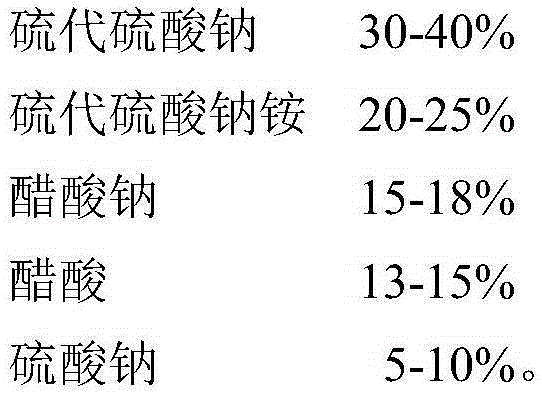

[0028] ⑵Fixer Concentrate

[0029]

[0030] Physical and chemical indicators

[0031] Sensitivity 2.7; contrast 6.0; fog: 0.08; maximum density >5.0, no crystallization at 0°C (-5°C to -10°C), suitable for low temperature transportation and storage.

[0032] Table 1 Measurement results of Agfa C7 industrial film photosensitive properties

[0033]

[0034]

[0035] The fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photosensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com