Method and system for combined treatment of household rubbish and fly ash

A domestic garbage and combined treatment technology, applied in the field of environmental engineering, can solve the problems of high entry cost, increase and transfer of heavy metal content, and achieve the effects of reducing energy consumption, high level of reduction, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

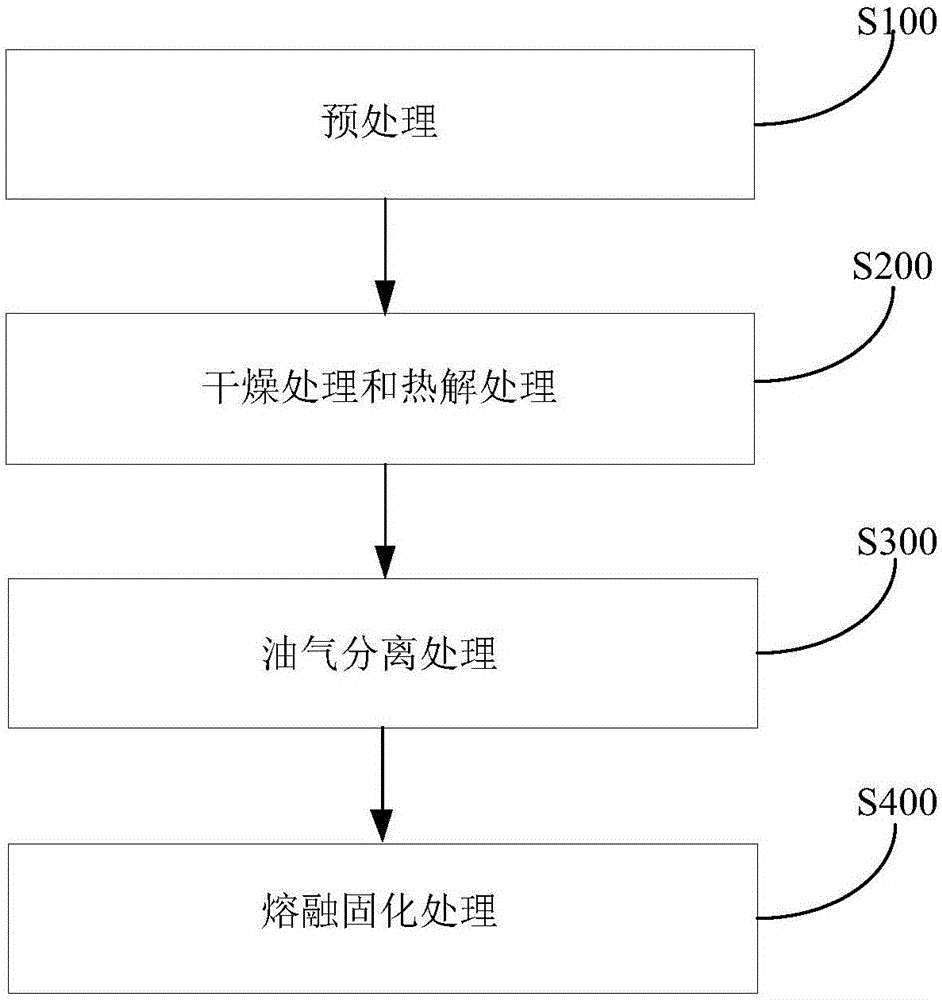

Image

Examples

Embodiment

[0063] The moisture content of domestic garbage to be treated is 55wt%, and its composition is shown in Table 1. The composition of fly ash to be treated is shown in Table 2.

[0064] Table 1 Household garbage composition (wt%)

[0065] name the fabric plastic Paper wood bamboo Kitchen waste muck glass, metal total wet base 3.53 25.96 14.94 7.44 28.91 11.58 7.64 100

[0066] Table 2 Composition characteristics of fly ash

[0067] Element Value / wt% heavy metal Content / mg / L Fe 2 o 3

5.49 Ni 92.6 MgO 1.87 Cd 52.9 CaO 12.19 Pb 883.5 TiO 2

1.16 Cu 598.3 Al 2 o 3

20.42 Zn 7294.7 SiO 2

48.95 Cr 101.2 K 2 o

2.03 Na 2 o

1.72

[0068] refer to Figure 5 , the domestic waste is pretreated, and the inorganic substances such as fabrics, plastics, glass and metals mixed in it are sorted out, and after being crushed, they are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com