An all-in-one machine for reducing ash, nitrogen, and temperature in flue gas of a straw-fired boiler and its implementation method

A straw boiler and boiler flue gas technology, which is applied in the direction of combustion methods, non-flammable liquid/gas transportation, combustion equipment, etc., can solve the problems of increasing boiler pipeline maintenance costs, large wear of straw boiler pipelines, waste of connecting flue materials, etc. , to achieve the effect of reducing raw material and labor costs, saving connecting flue, and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

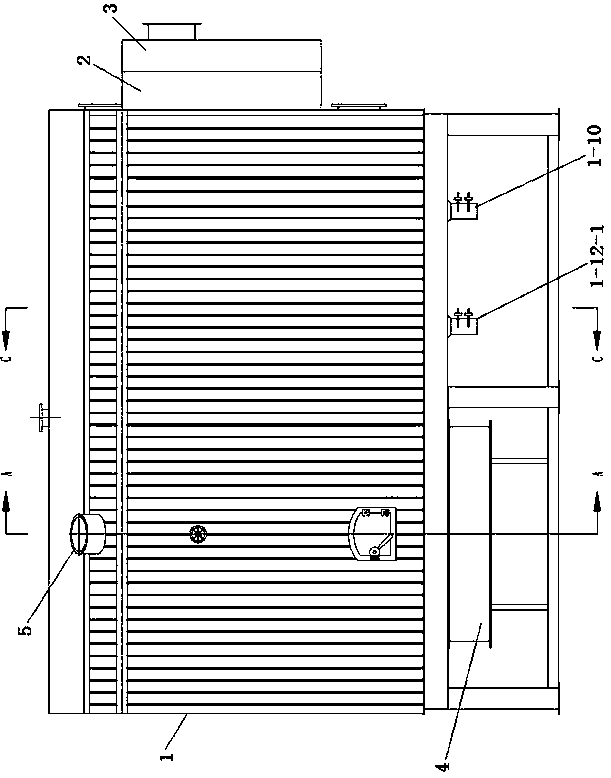

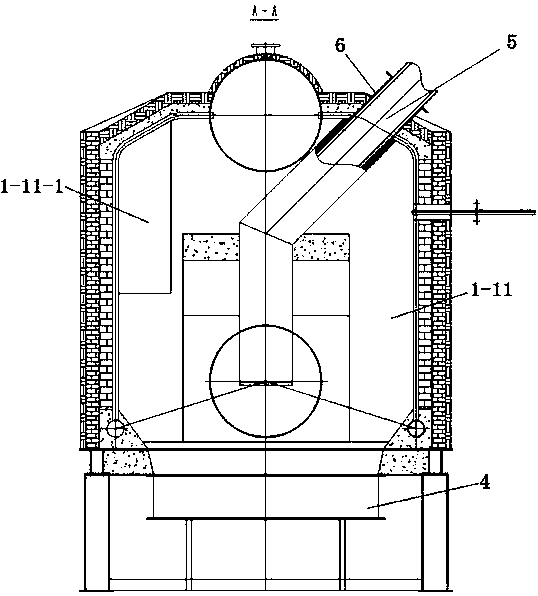

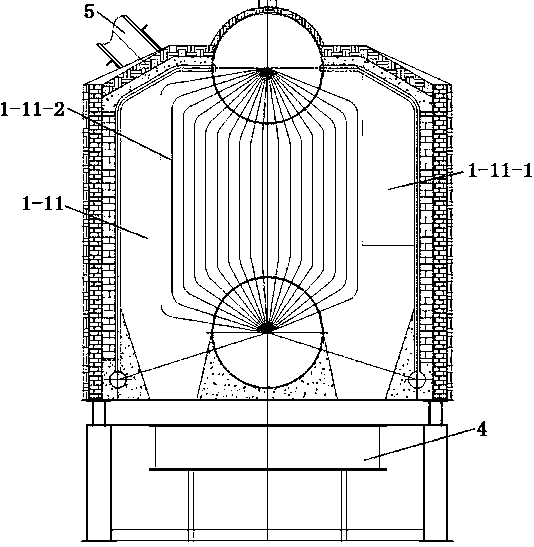

[0052] Such as Figure 1 to Figure 15 As shown, an integrated machine for reducing ash, nitrogen, and temperature in a straw-fired boiler includes a straw boiler body 1 , a low-temperature nitrogen removal device 2 , a heat exchange device 3 , a straw burner 4 , and a fuel feeding device 5 .

[0053] The fuel feeding device 5 includes a feeding pipe 5-1, an annular blocking plate 5-2, a secondary air duct pipe 5-3, a secondary air pan 5-4, and refractory concrete 5-5.

[0054] The secondary air disk 5-4 includes an upper ring disk 5-41, a lower ring disk 5-42, and an air distribution plate 5-43. The inner diameter of the upper ring disk 5-41 is larger than the inner diameter of the lower ring disk 5-42, and several air distribution plates 5-43 intervals are arranged to form several sub-air ducts between the upper ring plate 5-41 and the lower ring plate 5-42.

[0055] The lower end of the feed pipe 5-1 is a straight pipe, and the upper end is an inclined pipe. A secondary air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com