Lubricating oil circuit structure for heavy-duty transmission gear bearings of aeroengine

An aero-engine, heavy-duty transmission technology, applied in the direction of gear lubrication/cooling, transmission parts, belts/chains/gears, etc., can solve the reliability reduction of gear transmission system, insufficient injection lubrication scheme, and unsatisfactory lubrication effect, etc. problem, to achieve the effect of simple and ingenious structure, good lubrication effect and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

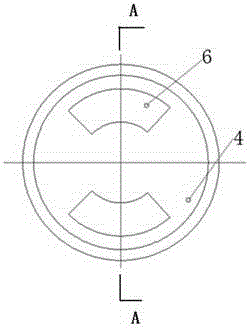

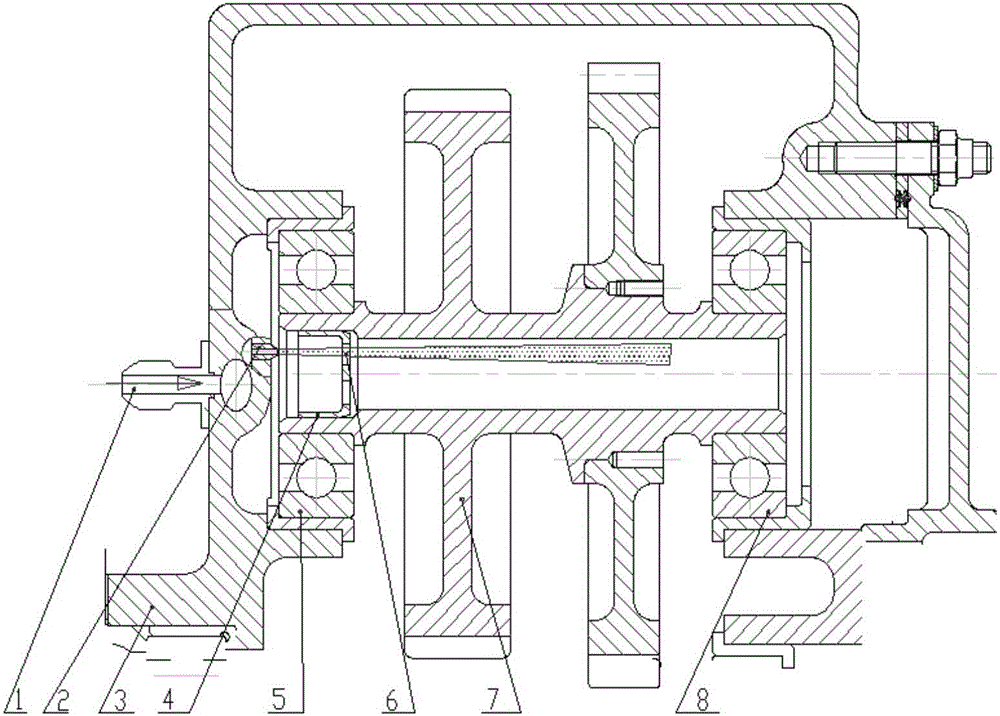

[0021] The lubricating oil circuit structure of the aero-engine heavy-duty transmission gear bearing described in this embodiment is as follows: figure 1 , Figure 3-1 , Figure 3-2 , Figure 4 and Figure 5 , which is composed of: a chamber is designed at one end of the shaft hole of the hollow gear shaft 7 installed in the gearbox 3 through bearings, and a lubricating oil flow distributor 4 is placed in the chamber, and the lubricating oil flow distributor is opposite to the gearbox. The lubricating oil nozzle 2 is set at the position, and the flow distributor 4 is a bushing sleeve designed with a through-flow hole 6 at the bottom of the cylinder. On the rotating annular surface of the bottom of the tube, the shape of the flow hole is a structure hole of the fan ring surface. There are two flow holes on the fan ring surface of the same shape, which are symmetrically arranged on the ring surface of the same diameter at the bottom of the cylinder. The area of the torus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com