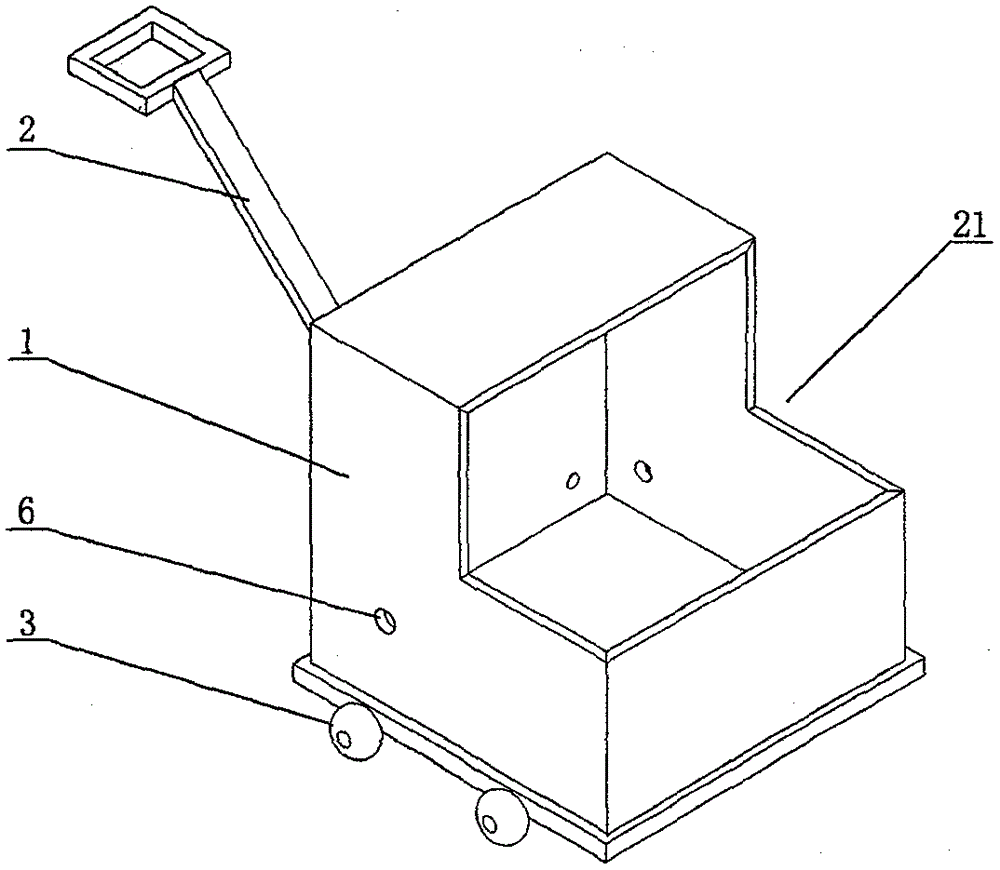

Multi-scale true-triaxial horizontal well hydrofracturing pressure bearing cylinder and using method

A hydraulic fracturing, true triaxial technology, applied in earthwork drilling, wellbore/well components, production fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

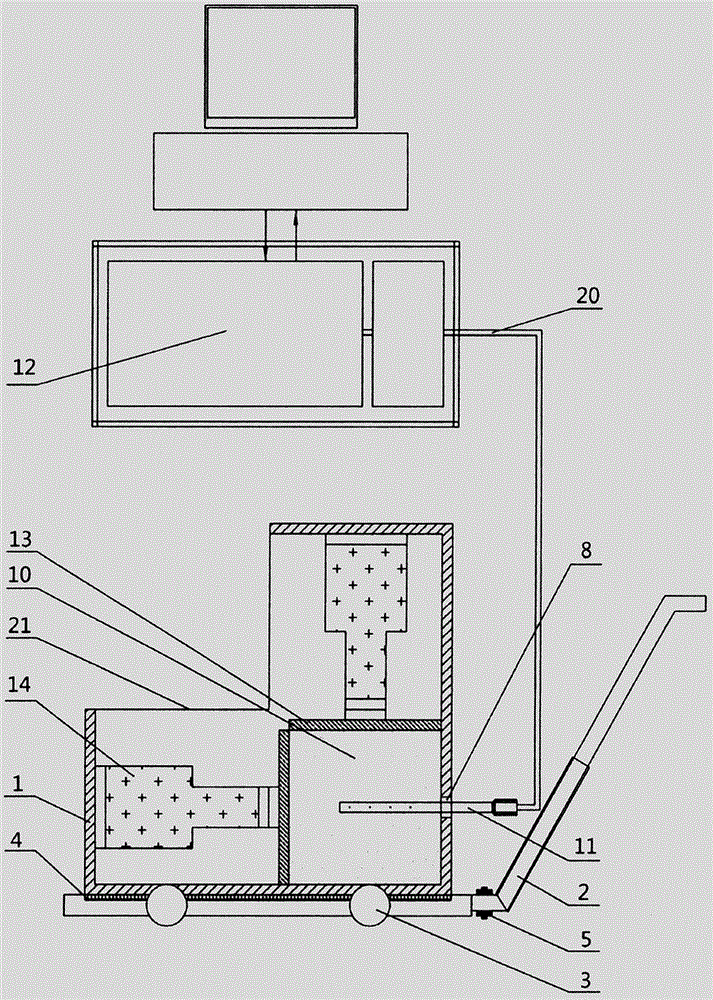

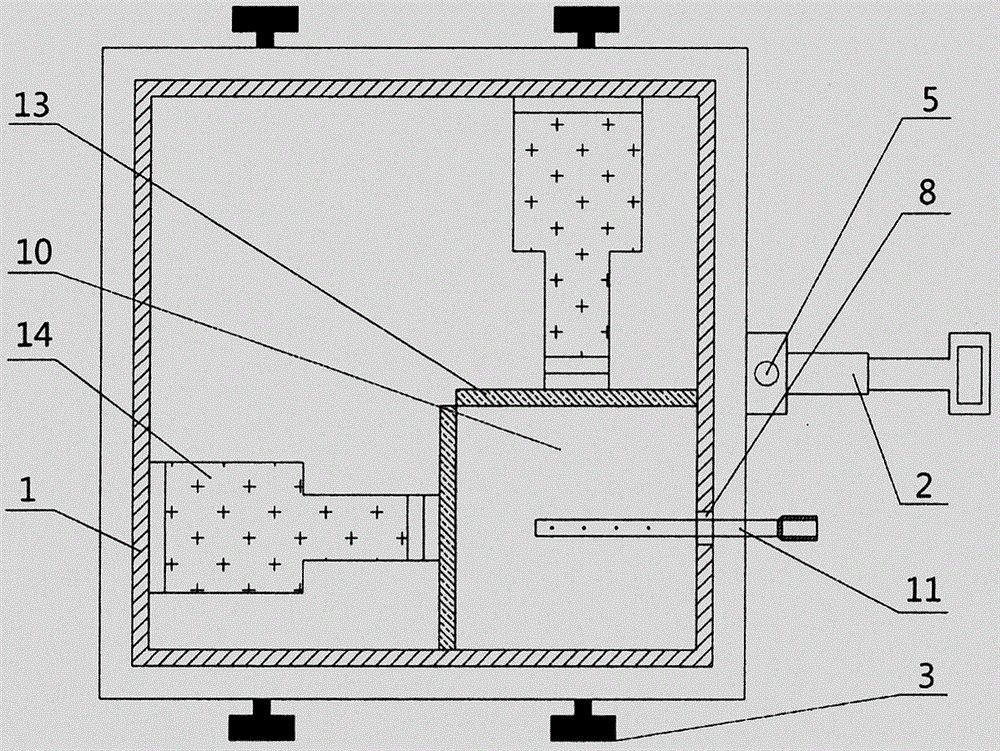

[0016] 1) Place the test rock sample (10) pre-buried with the horizontal wellbore (11) in the pressure-bearing cylinder (1), pass the horizontal wellbore through the corresponding passage hole, so that the three surfaces of the test rock sample (10) are in contact with the bearing The inner wall of the pressure cylinder (1) fits closely.

[0017] 2) Place the steel bearing plate (13) on the free surface on three sides of the test rock sample (10), connect the confining pressure loading system (14), and apply the set horizontal stress and vertical stress to the test rock sample.

[0018] 3) Connect the wellbore head (15) to the hydraulic fracturing control system (12) through the fracturing pipe (20), set the injection flow rate and flow rate, start the hydraulic fracturing control system (12), and monitor the hydraulic fracturing control system (12) at the same time. The pump pressure of the cracking system.

[0019] 4) After the test, observe the rock sample failure characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com