Semi-integrated seamless bridge structure adaptive to soft foundation

A semi-integral, seamless bridge technology, applied to bridges, bridge parts, bridge construction, etc., can solve the problem of increasing the axial force on the eccentricity of the center of gravity of the section, the increase of the arch deformation of the prefabricated beam section, and the span of the main beam. Problems such as cracking at the upper and middle edges can be eliminated, and the effects of reducing additional internal force, reducing material consumption, and simplifying the construction process can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

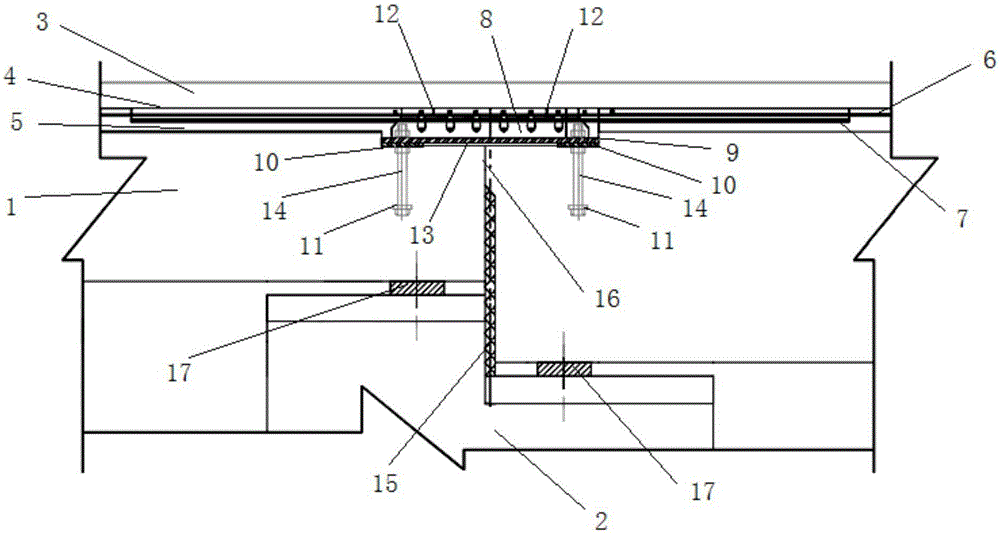

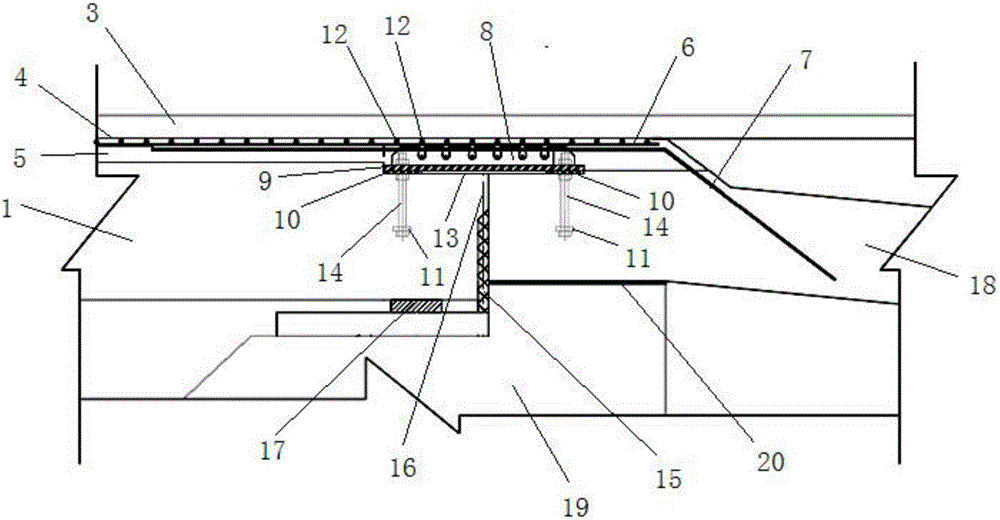

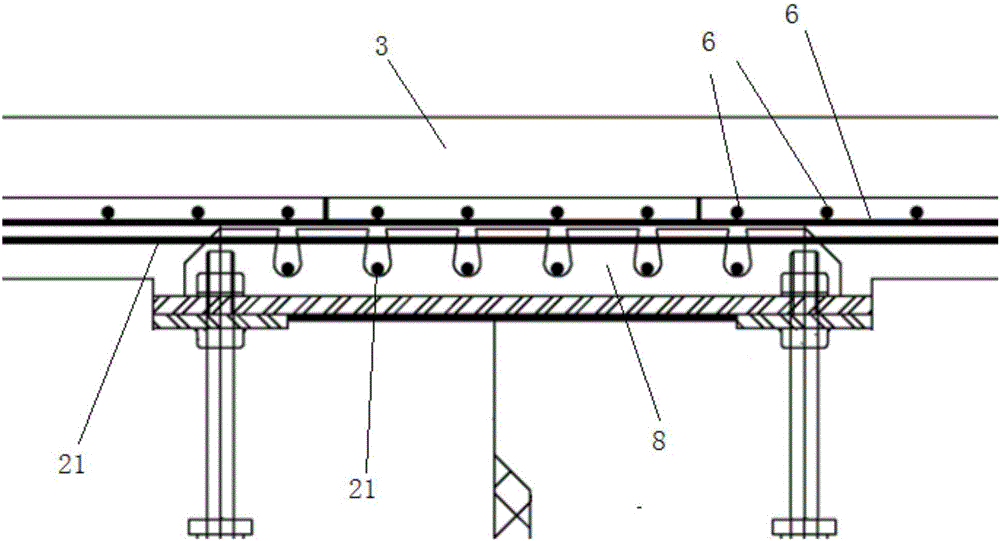

[0024] Such as Figure 1 to Figure 3 As shown, a semi-integral seamless bridge structure suitable for soft soil foundation includes main beam 1, bridge pier 2, slab 18, and abutment 19. The main beam 1 and the slab 18 are connected as a whole. Pave the leveling layer including the asphalt concrete paving 3, the waterproof layer 4, and the reinforced concrete paving layer 5 from top to bottom. The reinforced concrete paving layer 5 is provided with paving steel bars 6, and the main beam 1 includes several spans.

[0025] Among them, two adjacent spans are provided with tension and compression combination members, between the main beam 1 and the slab 18, there is a tension and compression combination member; there are tension and compression combination members including reinforcing steel bars 7, PBL shearing device openings Plate 8, perforated steel bars 21, tensile top plate 9, shallow embedded slab 10, deep embedded slab 11, and beam end trapezoidal bump compression rod 16.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com