An embedded rail vibration-damping fastener and its preparation method

A technology of embedded rails and vibration-absorbing fasteners, applied in the directions of rails, roads, fixed rails, etc., can solve the problem that aging resistance affects the service life of fasteners, aggravates the aging and service life of elastic parts, and the vibration reduction effect cannot be unsatisfactory. Satisfaction and other problems, to achieve the effect of enhancing anti-fatigue aging, solving poor vibration damping effect, and solving low lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

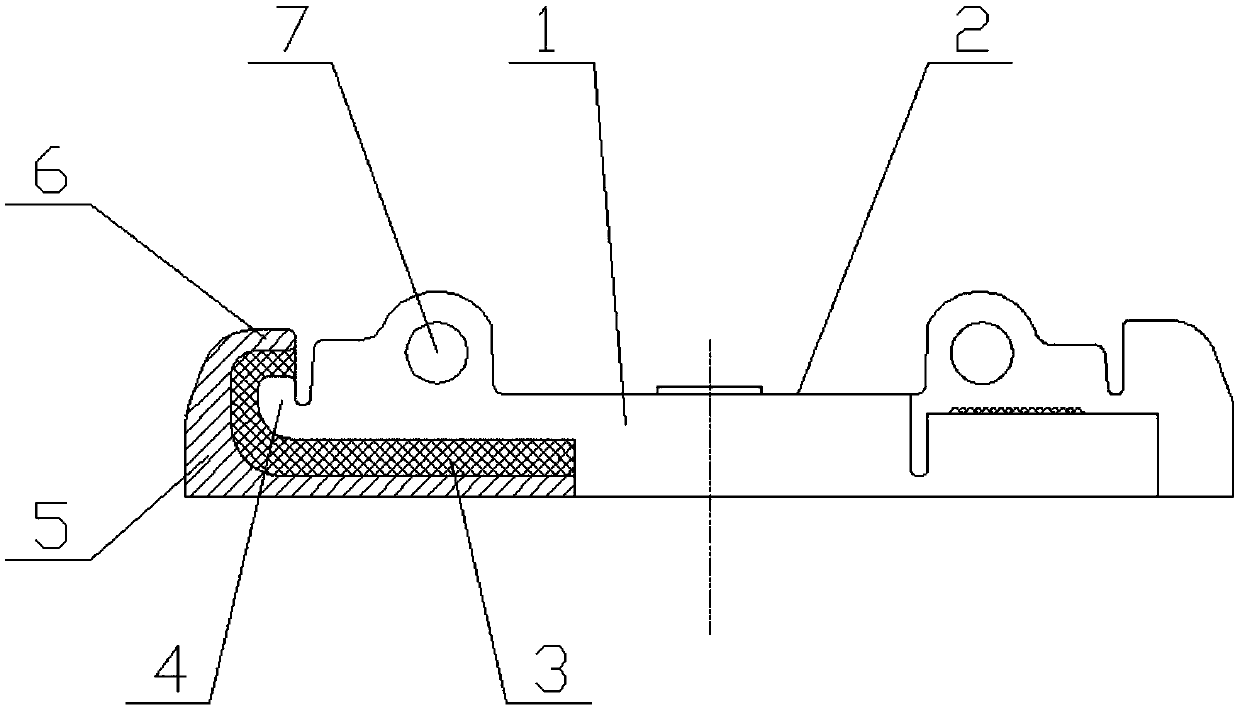

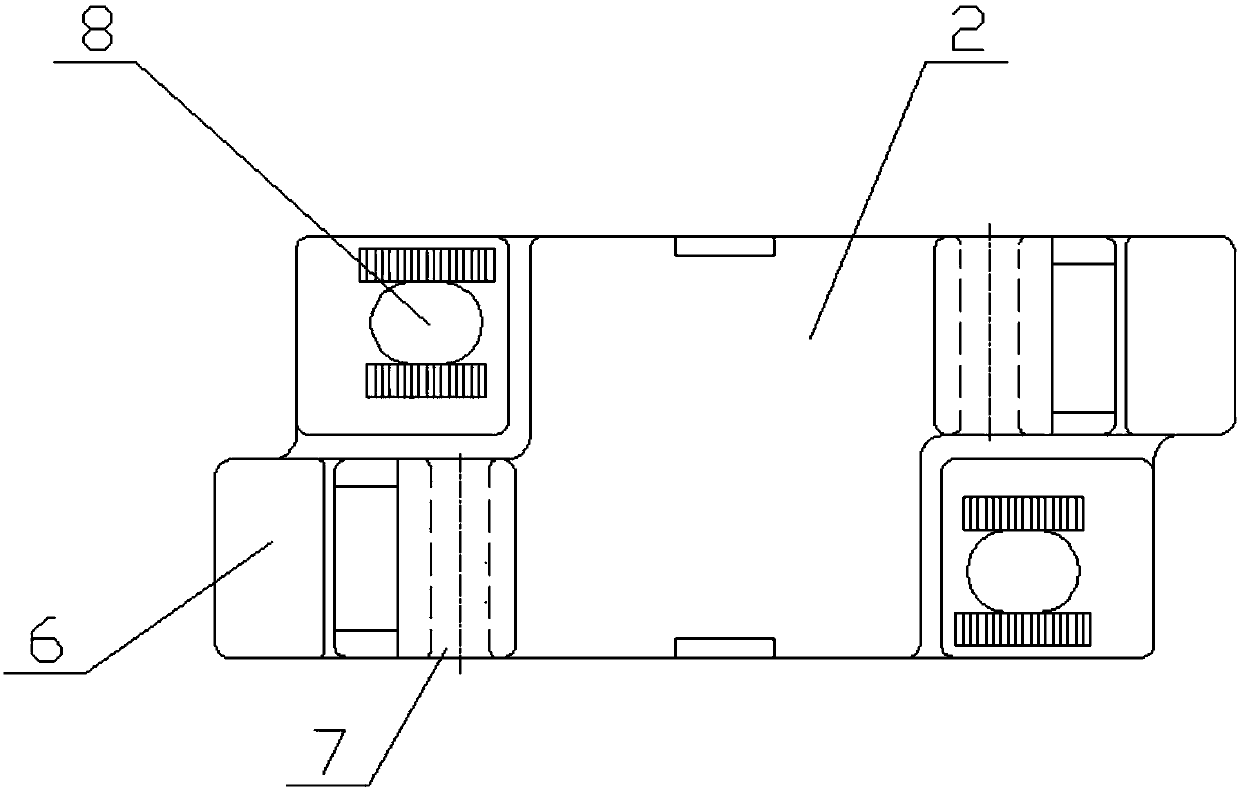

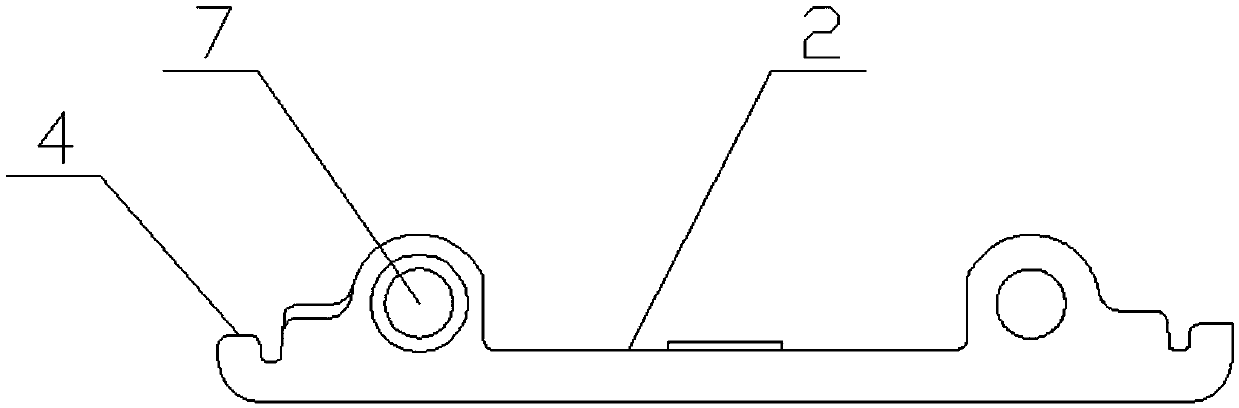

[0034] Such as Figure 1 to Figure 6 As shown, an embedded rail vibration-damping fastener of this embodiment includes a rail-supporting plate 1, a rail-supporting plate base 5, and an elastic member 3, wherein the elastic member 3 is specifically rubber; The top of the rail plate base 5 is fixedly connected with the elastic part 3, and the top of the elastic part 3 is provided with the rail plate 1; The design is different from the traditional rubber pad between the parts, but the elastic part 3, the rail plate 1 and the rail plate base 5 are vulcanized into a whole by two layers of adhesive under high temperature and high pressure.

[0035] The rail bearing plate 1 is a rectangular plate body structure, and a group of diagonals of the rail bearing plate 1 are concaved toward the middle of the rail bearing plate 1 to form a structure of a missing corner 9, wherein the edge shape of the missing corner 9 is a right angle; The middle part of the rail plate 1 is a rail bearing g...

Embodiment 2

[0049] The same features of this embodiment and embodiment 1 will not be repeated. The difference between this embodiment and embodiment 1 is that the thickness of the rail support plate is 16 mm, the thickness of the base of the rail support plate is set to 8 mm, and the width of the gap is 14 mm. , so that the thickness of the rubber filled in the gap is 14mm.

Embodiment 3

[0051] The same features of this embodiment and Embodiment 1 will not be repeated. The different features of this embodiment and Embodiment 1 are: the thickness of the rail support plate is 16.5mm, the thickness of the base of the rail support plate is set to 8.5mm, and the width of the gap is 14.5mm, so that the thickness of the rubber filled in the gap is 14.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com