a gearbox mount

A gearbox and mount technology, applied in the field of auto parts, can solve the problems of poor vibration isolation effect of gearbox mounts, difficult to meet the NVH performance of the whole vehicle, etc. The effect of creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

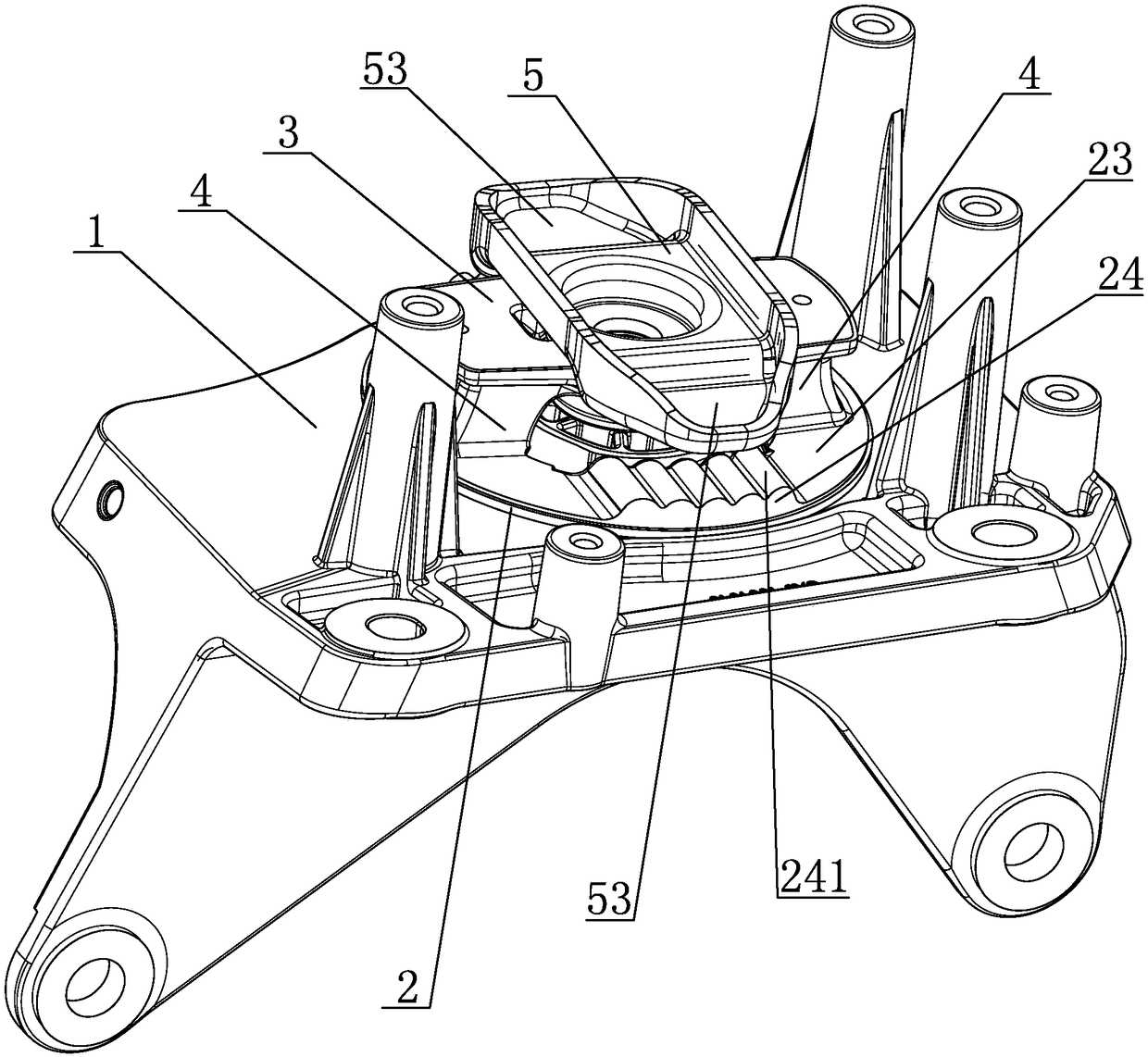

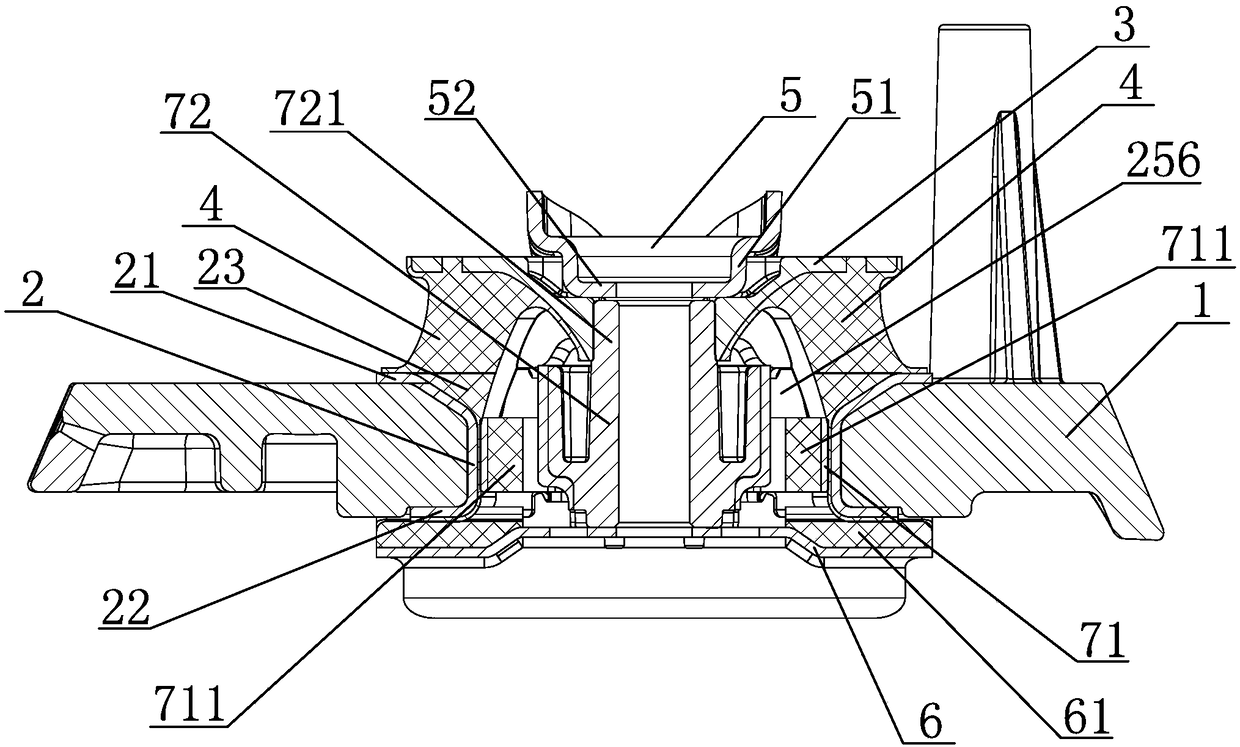

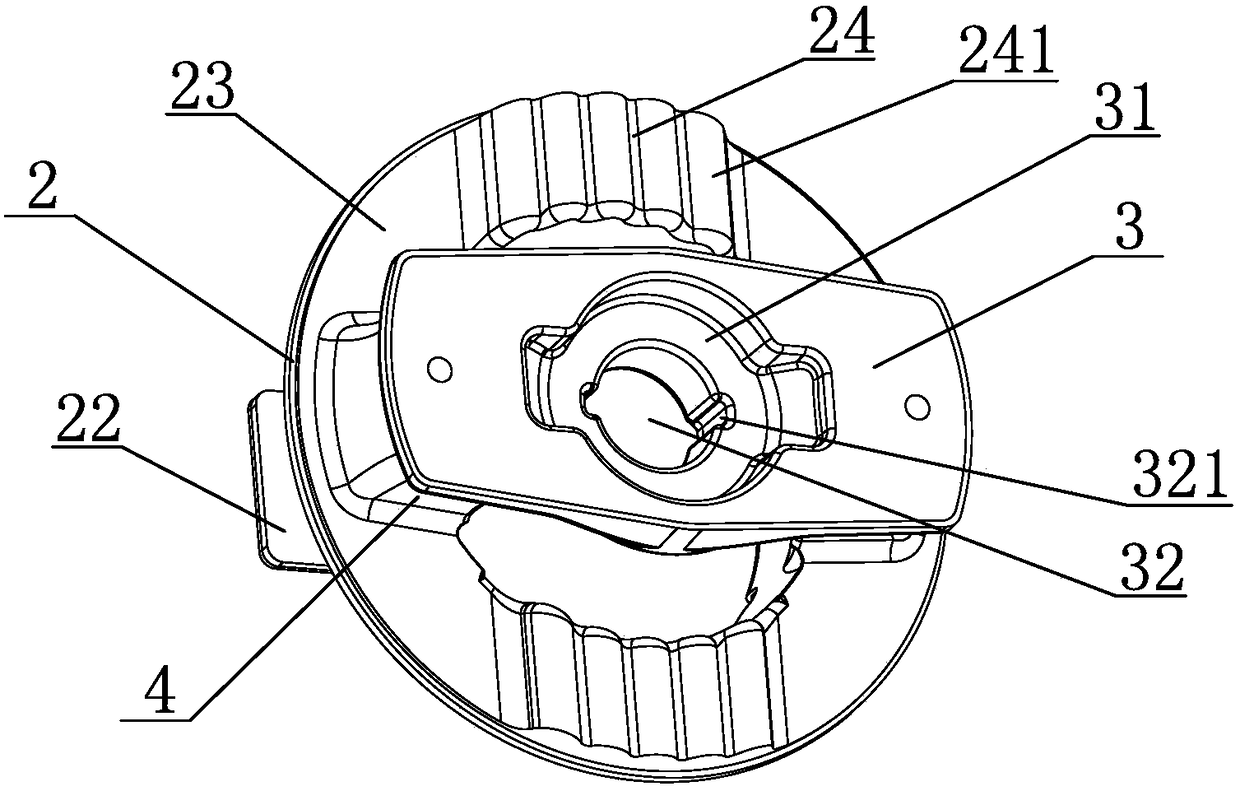

[0031] Embodiment one: Figure 1 to Figure 7 As shown, a gearbox suspension includes a bracket 1, and a first installation cavity 11 that penetrates up and down is arranged on the bracket 1. An outer frame 2 is arranged in the first installation cavity 11, and an inner frame 3 is arranged above the outer frame 2. The lower surfaces of the two ends of the inner frame 3 are symmetrically provided with supporting main springs 4, the upper end of the supporting main spring 4 is connected with the lower surface of the inner frame 3, and the lower end of the supporting main spring 4 is connected with the upper surface of the outer frame 2.

[0032] In this specific embodiment, the upper part of the outer frame 2 is turned outward to form an upper bent portion 21, and the upper bent portion 21 is arranged on the upper surface of the bracket 1, and the lower surface of the bracket 1 is provided with a limiting groove 12, and the outer frame 2 The lower part of 2 is turned outward to f...

Embodiment 2

[0046] Embodiment 2: other parts are the same as Embodiment 1, the difference is that the upper surface of the second rubber bumper 61 is composed of a plurality of upwardly protruding second arc-shaped surfaces 611 in a wave shape, as Figure 8 shown. The structural design has a small impact area to prevent abnormal noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com