Phosphate radical containing cotton modification material and preparation method and application thereof

A technology of modifying materials and phosphate radicals, which is applied in the field of analytical chemistry, can solve the problems of low modification amount of functional groups and the influence of adsorbent adsorption capacity, etc., and achieve the effects of less solvent consumption, increased practicability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

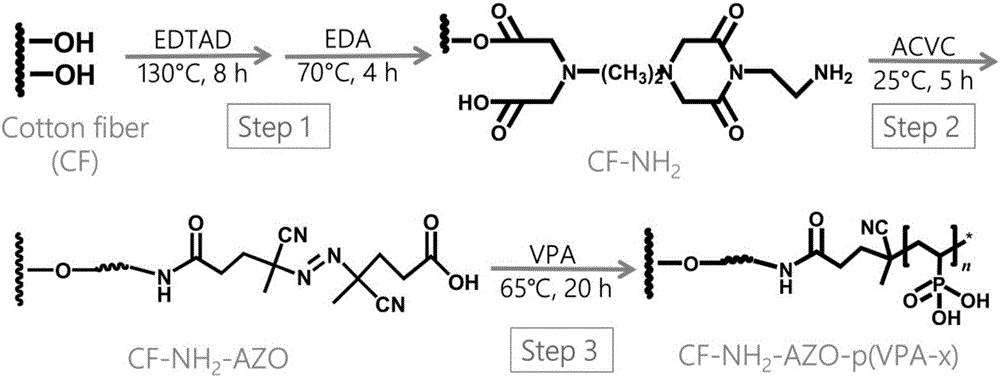

[0036] [Example 1] CF-NH 2 - Preparation of AZO-p(VPA-x)

[0037] First prepare amino-modified cotton to obtain CF-NH2 ; Then connect the free radical initiator to CF-NH 2 On, get CF-NH 2 -AZO; then surface-initiated polymerization in CF-NH 2 -AZO surface modified phosphate to get CF-NH 2 -AZO-p(VPA-x), as attached figure 1 shown.

[0038] where CF-NH 2 The preparation method is as follows: Weigh 0.5g of ethylenediaminetetraacetic dianhydride (EDTAD) into a 500mL round bottom flask, add 300mL of anhydrous N’N-dimethylamide (DMF), and then add 1.0g of absorbent cotton. After thorough mixing, react at 130° C. for 6 h under the condition of magnetic stirring. After the reaction was completed, it was cooled for a period of time, and the reaction liquid was poured out, and 300 mL of DMF was added again, and then 0.5 mL of ethylenediamine was added, and the reaction was carried out at 70° C. for 4 h under magnetic stirring conditions. The product was washed successively with...

Embodiment 2

[0041] [Example 2] CF-NH 2 -AZO-p(VPA-x)-M n+ preparation of

[0042] Prepare titanium sulfate aqueous solution (0.1M), zirconium oxychloride aqueous solution (0.1M), ferric chloride aqueous solution (0.1M) each 20mL, add 0.2g CF-NH to these three solutions respectively 2 -AZO-p(VPA-2), shake at room temperature for 5 hours. The product was washed successively with ethanol, water and acetone, and dried under vacuum at 60°C.

Embodiment 3

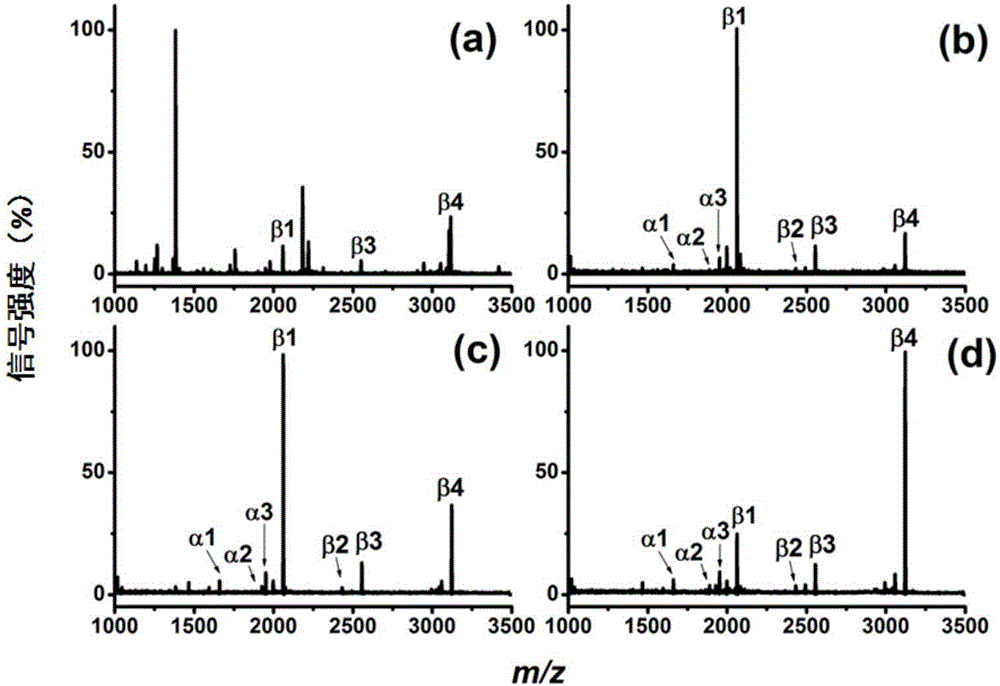

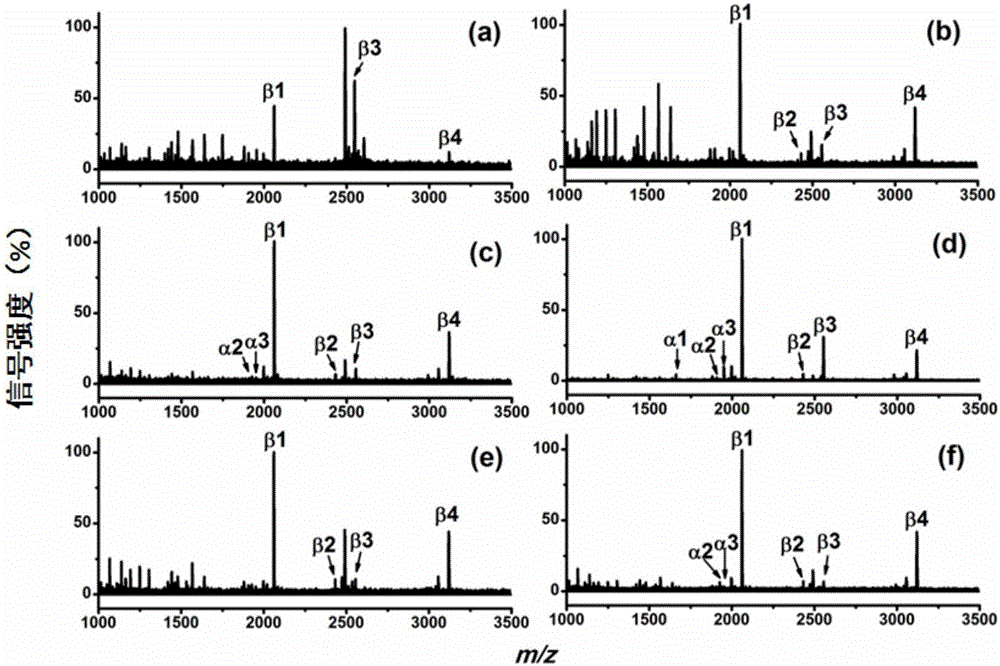

[0043] [Example 3] Three kinds of CF-NH 2 -AZO-p(VPA-2)-M n+ (M n+ = Ti 4+ , Zr 4+ ,Fe 3+ ) were applied to the selective enrichment of phosphorylated peptides in β-casein hydrolyzate

[0044] β-casein was prepared into a 1 mg / mL solution with 100 mM Tris-HCl (pH 8.5). Add trypsin to the above solution according to the ratio of enzyme to substrate ratio of 1:50 (w / w), and react at 37°C for 16h. The polypeptide product after enzymatic hydrolysis was drained by a vacuum centrifugal concentrator and stored in a -20°C refrigerator for later use.

[0045] Accurately weigh 5mg CF-NH2-AZO-p(VPA-2)-M n+ Extractions were performed in 1-mL disposable syringe needles. Use already balanced CF-NH 2 -AZO-p(VPA-2)-M n+ Repeatedly extract 100 μL of the mixture containing the peptide (3% TFA-50% ACN (v / v)). After washing twice with the sample solution, the analytes on the material were desorbed with 100 μL desorption solution (2.5% NH 3 ·H 2 O) Desorb into a centrifuge tube. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com