Dye finishing agent kettle in supercritical carbon dioxide anhydrous dyeing and finishing equipment

A carbon dioxide and finishing agent technology, which is applied in the processing of textile materials, equipment configuration for processing textile materials, liquid/gas/steam textile material processing, etc., can solve problems such as difficult to dissolve, and achieve the effect of increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

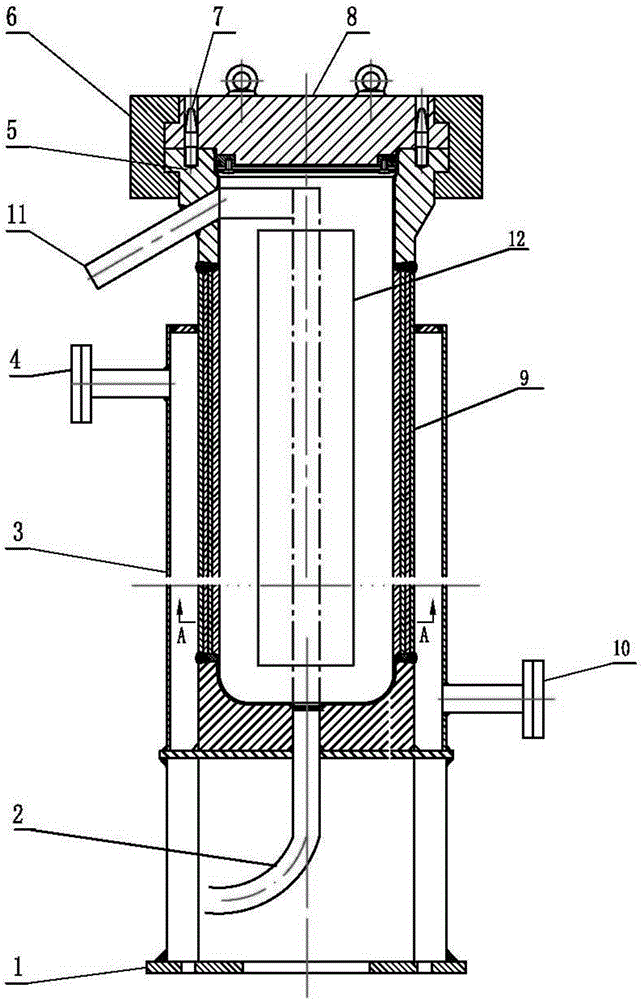

[0041] Place 1000g of Disperse Blue 60 in the sample chamber of the material unit in the dye finishing agent kettle. During the dyeing and finishing process, under the conditions of 120°C and 24MPa, supercritical carbon dioxide fluid enters the material unit 12 from the fluid inlet 101 and passes through the fluid distributor 102 After uniform distribution, it diffuses from the outside into the sample chamber composed of aggregation distributor I 103 and aggregation distributor II 104, blowing and dissolving the dye located therein. Carry the carbon dioxide that dyestuff enters fluid channel 105 through the hole that distributes on fluid channel 105 subsequently, flow through the fluid outlet 106 of material unit 12 and the carbon dioxide fluid outlet 11 of dye finishing agent kettle and enter into the dyeing and finishing tank that textiles is contained, realize its Dyeing of inner textiles. At the same time, the carbon dioxide fluid in the dyeing and finishing kettle flows o...

Embodiment 2

[0044] Place 500g of Disperse Red 60 in the sample chamber of the material unit in the dye finishing agent tank. During the dyeing and finishing process, under the conditions of 120°C and 30MPa, the supercritical carbon dioxide fluid enters the material unit 12 from the fluid inlet 101 and passes through the fluid distributor 102 After uniform distribution, it diffuses from the outside into the sample chamber composed of aggregation distributor I 103 and aggregation distributor II 104, blowing and dissolving the dye located therein. Carry the carbon dioxide that dyestuff enters fluid channel 105 through the hole that distributes on fluid channel 105 subsequently, flow through the fluid outlet 106 of material unit 12 and the carbon dioxide fluid outlet 11 of dye finishing agent kettle and enter into the dyeing and finishing tank that textiles is contained, realize its Dyeing of inner textiles. At the same time, the carbon dioxide fluid in the dyeing and finishing kettle flows o...

Embodiment 3

[0047] Place 100g of Disperse Yellow 119 in the sample chamber of the material unit in the dye finishing agent tank. During the dyeing and finishing process, under the conditions of 80°C and 15MPa, the supercritical carbon dioxide fluid enters the material unit 12 from the fluid inlet 101 and passes through the fluid distributor 102 After uniform distribution, it diffuses from the outside into the sample chamber composed of aggregation distributor I 103 and aggregation distributor II 104, blowing and dissolving the dye located therein. Carry the carbon dioxide that dyestuff enters fluid channel 105 through the hole that distributes on fluid channel 105 subsequently, flow through the fluid outlet 106 of material unit 12 and the carbon dioxide fluid outlet 11 of dye finishing agent kettle and enter into the dyeing and finishing tank that textiles is contained, realize its Dyeing of inner textiles. At the same time, the carbon dioxide fluid in the dyeing and finishing kettle flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com