A kind of medical titanium-based metal material and its manufacturing method

A metal-based, medical technology, which is applied in the field of manganese-doped medical titanium metal materials and its manufacturing, can solve the problems of insufficient antibacterial and osteogenic healing performance, and achieve improved antibacterial and osteogenic performance, good antibacterial performance, and stable preparation process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] After a 10mm×10mm×1mm pure titanium sheet was ultrasonically treated twice (5 minutes each time) with mixed acid (hydrofluoric acid: nitric acid: deionized water = 1:5:34), it was washed with acetone, ethanol and deionized water in sequence. Ultrasonic cleaning was performed twice for 5 minutes each time. Using plasma immersion ion implantation technology, the manganese element is implanted into the titanium substrate. The specific process parameters are shown in Table 1:

[0043] Table 1 Manganese ion implantation parameters

[0044] Injection voltage (kV)

30

Pulse width (μs)

500

Injection time (h)

1h

Background vacuum (Pa)

5×10 -3

Frequency (Hz)

5

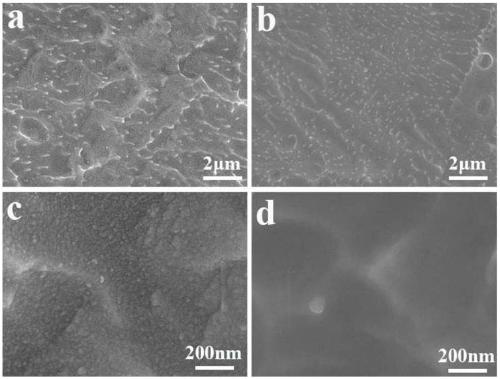

[0045] figure 1 It is a comparison diagram of the scanning electron microscope morphology of the titanium metal material obtained through the modification treatment of this embodiment and the pure titanium surface. In the figure: a / c is pure titanium, and b / d is...

Embodiment 2

[0048] After a 10mm×10mm×1mm pure titanium sheet was ultrasonically treated twice (5 minutes each time) with mixed acid (hydrofluoric acid: nitric acid: deionized water = 1:5:34), it was washed with acetone, ethanol and deionized water in sequence. Ultrasonic cleaning was performed twice for 5 minutes each time. Using plasma immersion ion implantation technology, the manganese element is implanted into the titanium substrate. The specific process parameters are shown in Table 2:

[0049] Table 2 Manganese ion implantation parameters

[0050] Injection voltage (kV)

30

Pulse width (μs)

800

Injection time (h)

1h

Background vacuum (Pa)

5×10 -3

Frequency (Hz)

5

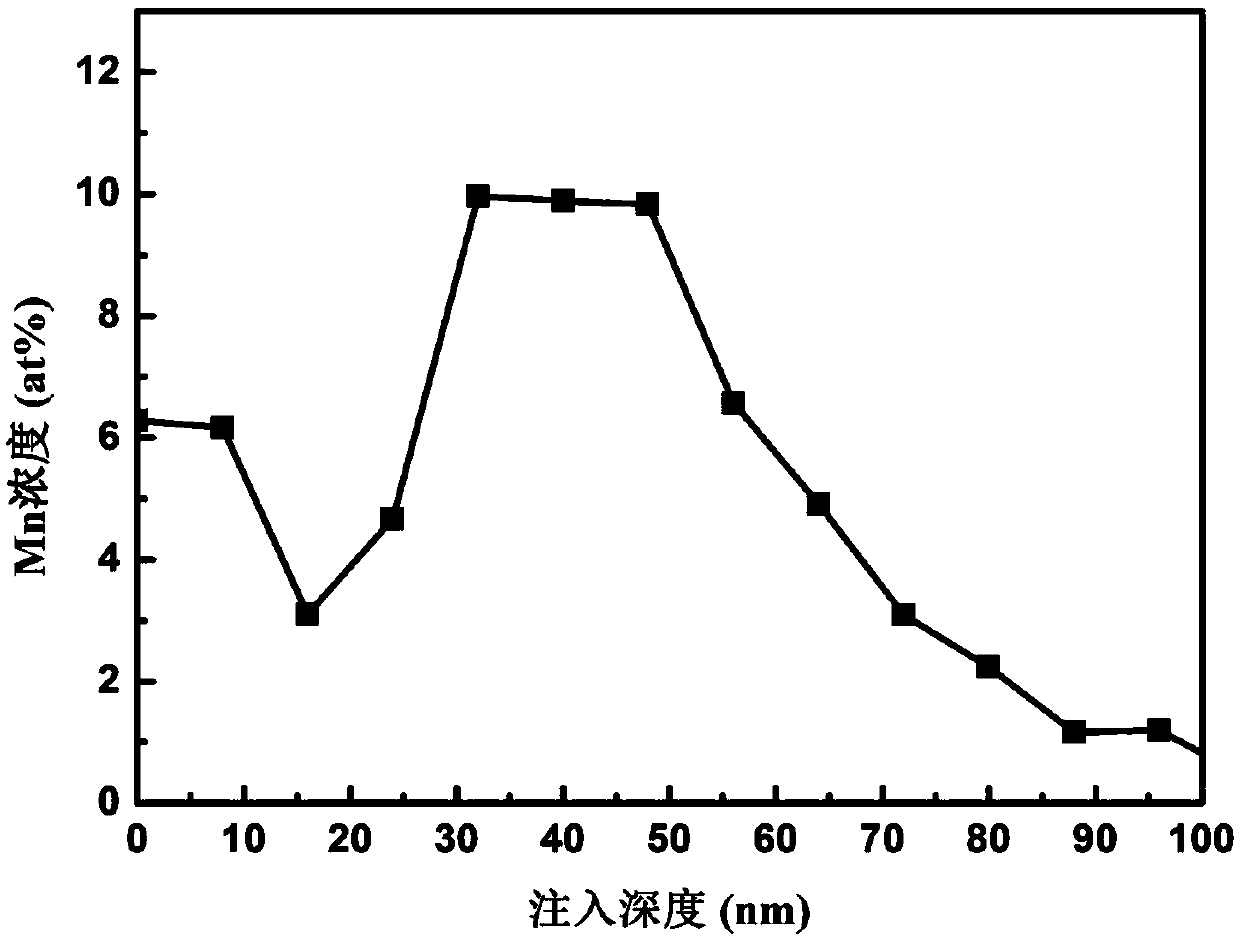

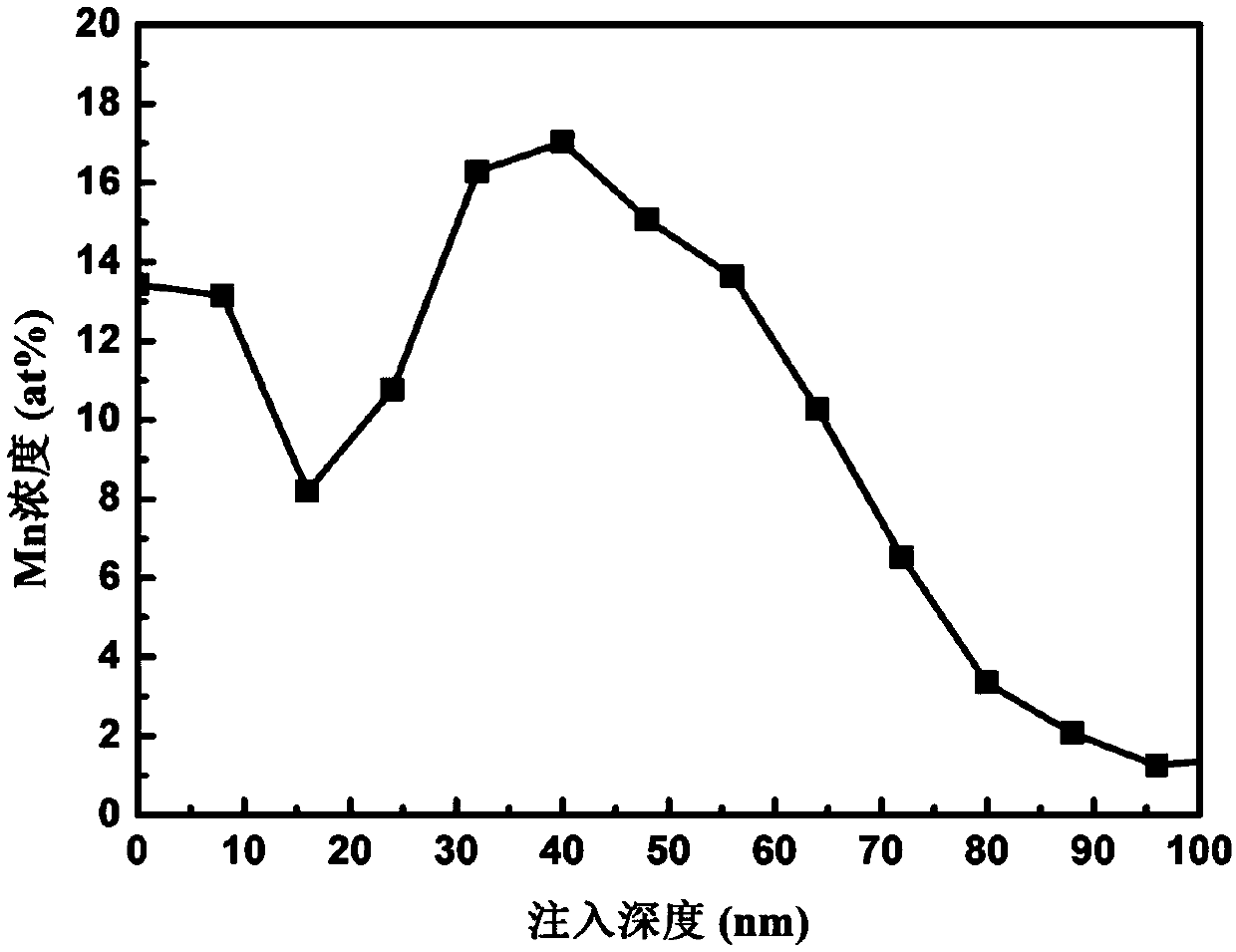

[0051] image 3 It is the manganese element XPS depth distribution diagram of the manganese doped modified layer obtained through the modification treatment of this embodiment. Depend on image 3 It can be seen that the manganese ion implantation depth of the ...

Embodiment 3

[0055] After a 10mm×10mm×1mm pure titanium sheet was ultrasonically treated twice (5 minutes each time) with mixed acid (hydrofluoric acid: nitric acid: deionized water = 1:5:34), it was washed with acetone, ethanol and deionized water in sequence. Ultrasonic cleaning was performed twice for 5 minutes each time. Using plasma immersion ion implantation technology, the manganese element is implanted into the titanium substrate. The specific process parameters are shown in Table 3:

[0056] Table 3 Manganese ion implantation parameters

[0057] Injection voltage (kV)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com