Aluminum strontium alloy production process

A production process, aluminum-strontium alloy technology, applied in the field of aluminum-strontium alloy production process, can solve the problems that the production process cannot be continuously extruded and the efficiency is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below by means of specific embodiments:

[0025] The production process of aluminum-strontium alloy includes four processes of batching, smelting, casting and extrusion. in:

[0026] Ingredients: select aluminum ingots and strontium ingots, weigh 100kg of strontium ingots and 1000kg of aluminum ingots according to the ratio of 1:10, and carry out ingredients.

[0027] Smelting:

[0028] Step 1), put the aluminum ingot into the smelting furnace, heat up to melt the aluminum ingot into aluminum liquid;

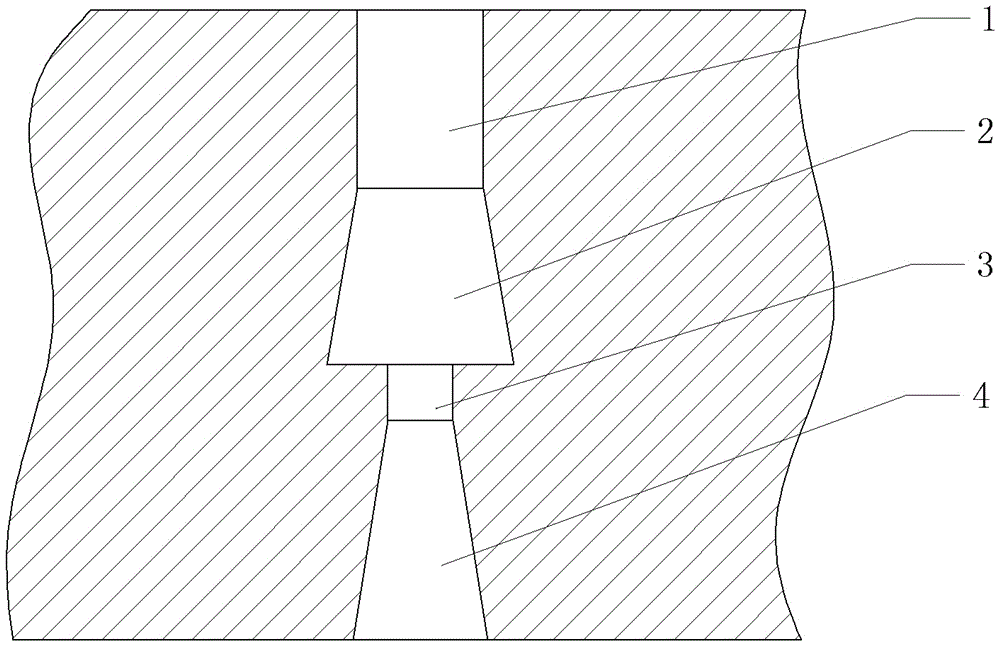

[0029] Step 2) Raise the temperature of the molten aluminum to 771-850°C, and press the strontium ingot into the molten aluminum with a special tool. The special tool includes a support rod. The air passage communicated with the cover, and a plurality of through holes are uniformly distributed on the wall of the cover. During the process of pressing the strontium ingots into the aluminum liquid to melt the stro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com