Mechanical continuous threshing device for agricultural harvesting

A threshing device and mechanical technology, which is applied in agricultural machinery and equipment, agricultural machinery and tools, agriculture, etc., can solve the problems of seed doping residue, insufficient screening effect, and fast moving speed of sunflowers, so as to improve the threshing effect and improve Vibration frequency, the effect of improving the screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

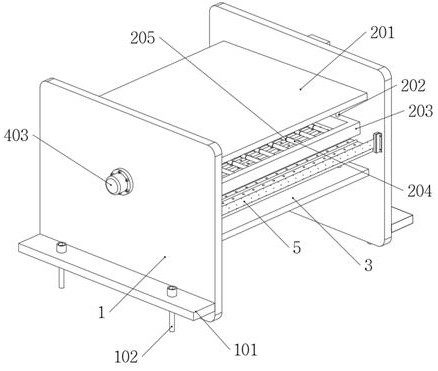

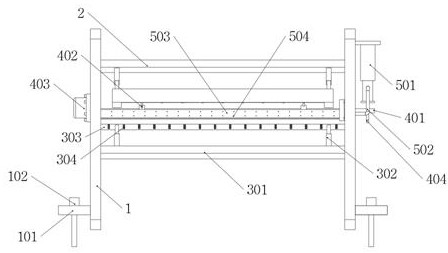

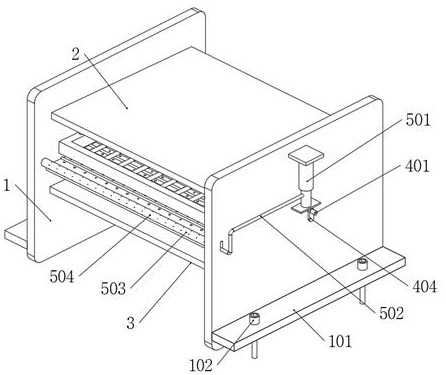

[0038] Example: please refer to Figure 1 to Figure 8 :

[0039] The present invention provides a mechanical continuous threshing device for agricultural harvesting, comprising: a casing 1, a threshing part 2, a screening part 3, a driving part 4 and a cleaning part 5;

[0040] Two fixed seats 101 are symmetrically welded on the shell 1;

[0041] The threshing part 2 is composed of a top plate 201, an elastic telescopic rod A202, a mounting seat 203, a blocking rod 204 and a protrusion A205, and the top plate 201 is fixedly connected to the casing 1 by bolts;

[0042] The screening part 3 is composed of a bottom plate 301, an elastic telescopic rod B302, a screening plate 303, a through hole 304 and a protrusion B305, and the bottom plate 301 is fixedly connected to the casing 1 by bolts;

[0043]The driving part 4 is composed of a rotating shaft 401, a toggle rod 402, a driving motor 403 and a toggle block 404, and the rotating shaft 401 is rotatably connected to the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com