Preparation method for oxidized pellet ore raw materials and oxidized pellet ore

A technology of oxidizing pellets and raw materials, which is applied in the field of iron and steel smelting, can solve the problems of high iron content in iron oxide scale, unusable dust and sludge, and large investment in equipment, so as to achieve the effect of reasonable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Correspondingly, the present invention also provides a method for preparing oxidized pellets, which includes the following steps:

[0033] Step a: Provide the above-mentioned oxidized pellet raw materials, and fully mix the raw materials in a strong mixer to obtain a mixture;

[0034] Step b, pelletizing the mixture in a pelletizing tray to obtain green pellets;

[0035] Step c, drying, preheating, roasting, soaking, and then cooling the green balls to finally oxidize the pellets.

[0036] Preferably, in the step c,

[0037] The drying conditions are as follows: the temperature is 150-250°C, and the time is 15-30 min;

[0038] The preheating conditions are as follows: the temperature is 600-900°C, and the time is 8-10 minutes;

[0039] The baking conditions are as follows: the temperature is 1260-1290°C, and the time is 5-10 min;

[0040] The conditions of the soaking are as follows: the temperature is 800-1000°C, and the time is 3-5 min.

[0041] The invention provides an oxidized p...

Embodiment 1~2

[0043] Examples 1-2, comparative examples

[0044] 1. Provide the above-mentioned oxidized pellet raw materials, and fully mix the raw materials in a strong mixer to obtain a mixture; the raw material batching plan of each embodiment is listed in Table 1; the composition of each raw material is listed in Table 2;

[0045] 2. The mixture is pelletized in a pelletizing tray to obtain green balls; the water content and properties of the green balls are listed in Table 3;

[0046] 3. The green balls are dried, preheated, roasted, soaked, and then cooled to finally oxidize the pellets. Please refer to Table 4 for specific process parameters, the chemical composition of the prepared oxidized pellets is listed in Table 5, and the compressive strength is listed in Table 6.

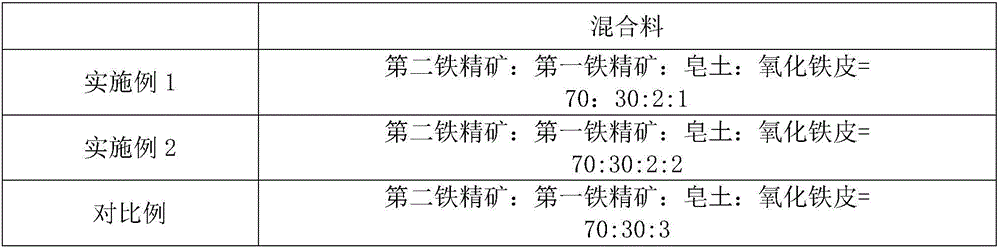

[0047] Table 1 Example raw material preparation scheme

[0048]

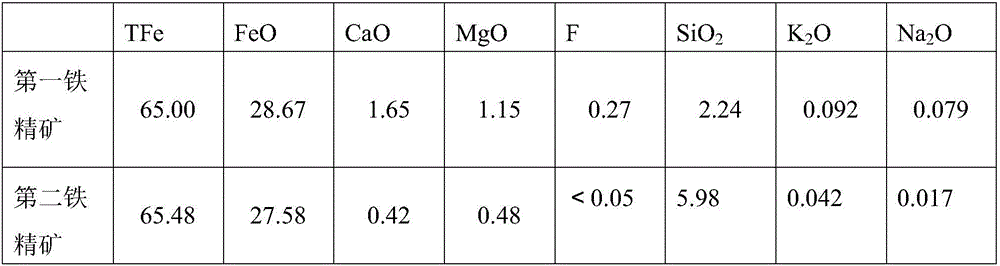

[0049] Table 2 Ingredients of raw materials in Examples

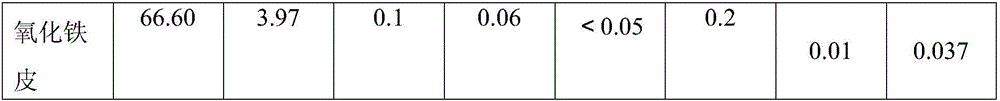

[0050]

[0051]

[0052] The first fine iron ore origin: Baotou Steel's Baiyun Obo Mine.

[0053] Th...

Embodiment 3~4

[0063] The firing temperature was 1260°C and 1290°C, and the other steps were the same as in Example 2. The compressive strength of the finished ball was tested, which is listed in Table 7.

[0064] Table 6 Example 2-4 Compressive strength of finished pellets

[0065] Compressive strength Example 2 2364N / P Example 3 2167N / P Example 4 2773N / P

[0066] From the above content, it can be seen that using the oxidized pellet raw materials provided by the present invention and the green pellets prepared by the above process, the drop strength, green pellet compressive strength, and dried pellet compressive strength can meet the technical requirements of pelletizing technology. The finally prepared oxidized pellets can meet the technical requirements of blast furnace production. The addition of iron oxide scale is conducive to the improvement of taste. Moreover, as the roasting temperature increases, the compressive strength of the finished pellets gradually increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com