Fuel gradation homoenergetic sintering method

A combustion method and fuel grading technology, applied in the field of iron ore powder belt sintering, can solve the problems of sinter yield reduction, uneven sinter quality, and increased sintering energy consumption, etc., to achieve reduced solid fuel consumption, drum The strength and the average particle size of finished ore are improved, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

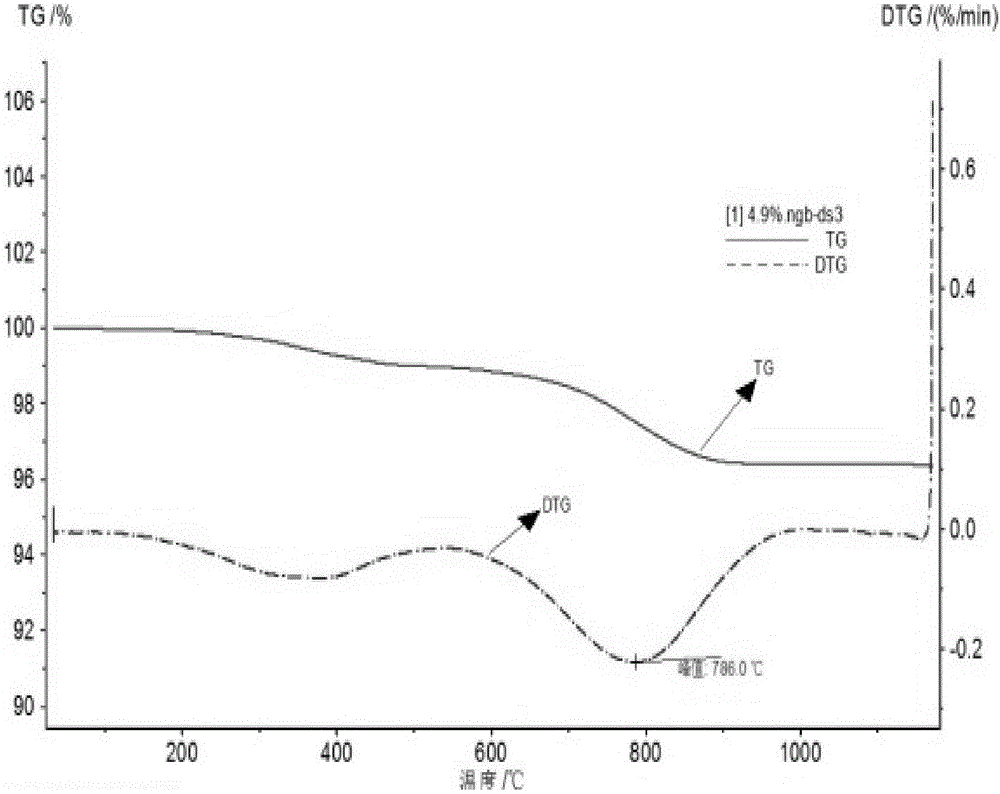

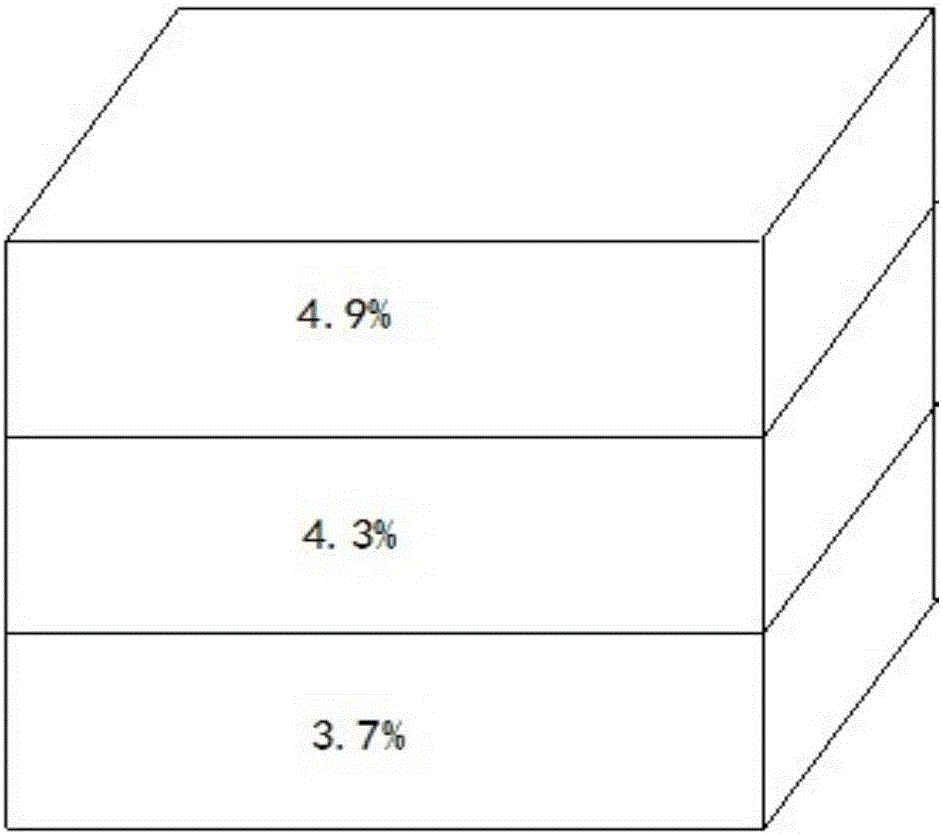

[0027] Such as figure 1 As shown in the figure, a method for sintering fuel graded, including batching, mixing, cloth ignition, draft sintering, cooling and screening, performance testing process. The present invention focuses on improving the material distribution stage, taking the sintering process of a certain steel factory as an example. In the material layer of the sintering machine trolley, it is evenly divided into three layers according to the mass fraction of solid fuel, and the proportions are 4.9%, 4.3%, and 3.7% respectively; the particle size ranges from the upper layer to the lower layer. -5mm, lower layer 6-15mm. In the sintering process, the "automatic heat storage" feature of the material layer can be used to reduce the consumption of solid fuel; the particle size of the solid fuel can be changed to improve the air permeability of the material layer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com