Method for increasing co-liquefaction conversion rate of low-rank coal/naphthenic base vacuum residue and diesel fraction content

A technology of vacuum residue and naphthenic group, which is applied in the preparation of liquid hydrocarbon mixture, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of low conversion rate of binary co-liquefaction, etc. Distillate content of diesel oil and the effect of preventing coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

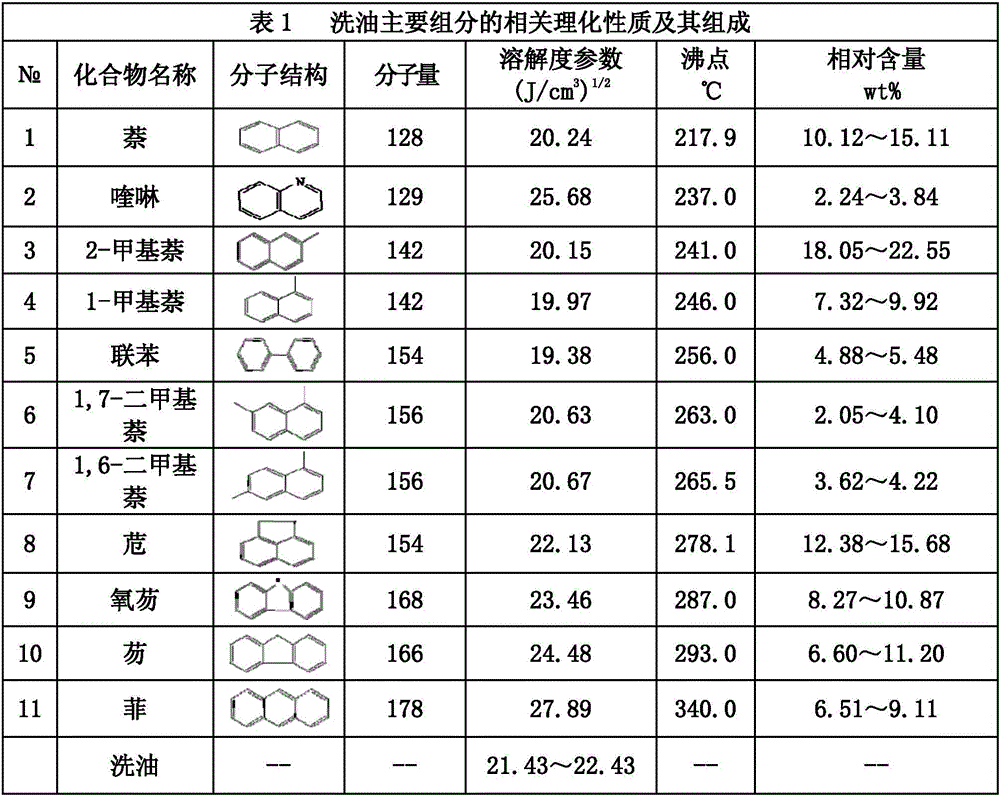

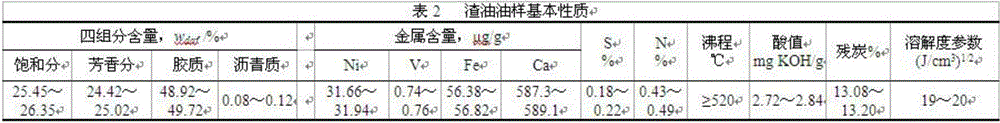

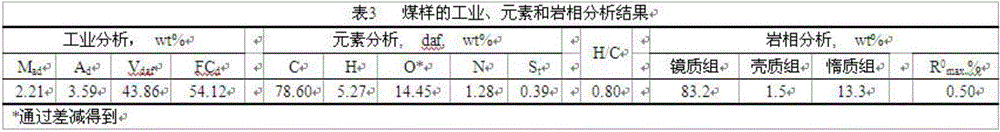

[0014] Embodiment 1, the method for improving the co-liquefaction conversion rate of low-rank coal / naphthenic vacuum residue and the content of diesel fractions, the raw materials include 7 to 13 parts of low-rank coal, naphthenic vacuum residue 7 parts to 13 parts and 15 parts to 25 parts of washing oil, the method for improving the co-liquefaction conversion rate of low-rank coal / naphthenic vacuum residue and the content of diesel fraction is carried out as follows: the first step, the required amount The naphthenic vacuum residue and wash oil are mixed and stirred to obtain a mixed oil sample; in the second step, the required amount of low-rank coal and catalyst are added to the mixed oil sample and stirred to prepare a low-rank coal / naphthenic Vacuum residue / wash oil ternary mixed oil coal; the third step, add low-rank coal / naphthenic vacuum residue / wash oil ternary mixed oil coal and agate balls into the ball mill tank on the ball mill, and add Low-rank coal / naphthenic va...

Embodiment 2

[0028] Embodiment 2, the method for improving the co-liquefaction conversion rate of low-rank coal / naphthenic vacuum residue and the content of diesel fraction, the raw materials include 7 or 13 parts of low-rank coal, naphthenic vacuum residue 7 parts or 13 parts and 15 parts or 25 parts of washing oil, the method for improving the co-liquefaction conversion rate of low-rank coal / naphthenic vacuum residue and the content of diesel fraction is carried out as follows: the first step, the required amount The naphthenic vacuum residue and wash oil are mixed and stirred to obtain a mixed oil sample; in the second step, the required amount of low-rank coal and catalyst are added to the mixed oil sample and stirred to prepare a low-rank coal / naphthenic Vacuum residue / wash oil ternary mixed oil coal; the third step, add low-rank coal / naphthenic vacuum residue / wash oil ternary mixed oil coal and agate balls into the ball mill tank on the ball mill, and add Low-rank coal / naphthenic vac...

Embodiment 3

[0029] Embodiment 3, as the optimization of above-mentioned embodiment, in the second step, catalyzer is ferric oxide and sulfur, and wherein ferric oxide is 0.9 part to 1.1 part by weight, and sulfur is 0.4 part by weight to 0.6 share.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com