Interpenetrating polymer network jelly and preparation method and application thereof

A technology of polymer and jelly, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of inability to withstand formation water scouring, affecting the effect of plugging agents, shortening gel time, etc. Good blocking effect, good blocking ability and wide temperature adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Preparation of interpenetrating polymer network jelly with different polyacrylamide mass concentrations

[0051] Prepare 4 sets of interpenetrating polymer network jelly gels, the mass concentrations of PAM are 0.8%, 1.0%, 1.2%, 1.4%, water-soluble phenolic resin 0.9wt%, acrylamide 7.0wt%, starch 3.0wt% %, ammonium persulfate 0.1wt%, N,N-methylenebisacrylamide 0.04wt%, the preparation method is as follows:

[0052] (1) Weigh 47.7g of distilled water, draw 0.8g, 1.0g, 1.2g, and 1.4g of polyacrylamide dropwise along the tangential direction with a syringe according to the ratio during stirring, and add water-soluble 0.9 g of phenolic resin.

[0053] (2) Weigh 40g of each of the four groups of distilled water, dissolve 3g of starch in the four groups of boiling water, stir until completely dissolved, then cool to room temperature and then add 7g of acrylamide, 0.1g of ammonium persulfate and 0.04g of N to each group according to the proportion, N-methylenebisa...

Embodiment 2

[0058] Example 2: Preparation of interpenetrating polymer network gels with different acrylamide mass concentrations

[0059] Prepare 4 sets of interpenetrating polymer network jelly gel solutions, the mass concentrations of acrylamide are 5%, 6%, 7%, 8%, polyacrylamide 1.4wt%, water-soluble phenolic resin 0.9wt%, starch 3.0wt%, ammonium persulfate 0.1wt%, N,N-methylenebisacrylamide 0.04wt%, the preparation method is as follows:

[0060] (1) Weigh 47.7g of four groups of distilled water, draw 1.4g of polyacrylamide with a syringe according to the ratio during the stirring process and drop them in along the tangential direction, stir evenly and add 0.9g of water-soluble phenolic resin to each group according to the ratio.

[0061] (2) Weigh 40g of each of the four groups of distilled water, dissolve 3g of starch in the four groups of boiling water, stir until completely dissolved, then cool to room temperature and then add 5g, 6g, 7g, 8g of acrylamide and 0.1g of supernatant to...

Embodiment 3

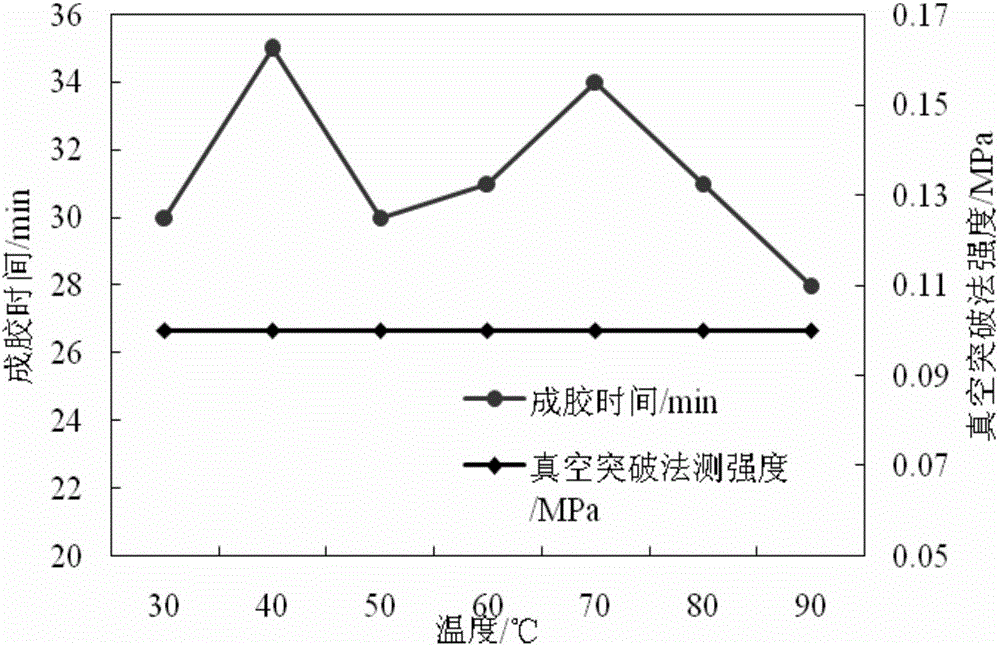

[0067] Example 3: Changes in gelation time of interpenetrating polymer network jelly under different temperature environments

[0068] Prepare 7 groups of interpenetrating polymer network jelly gels, polyacrylamide 1.4wt%, water-soluble phenolic resin 0.9wt%, starch 3.0wt%, acrylamide mass concentration 7%, ammonium persulfate 0.1wt %, N,N-methylenebisacrylamide 0.04wt%, the preparation method is as follows:

[0069] (1) Weigh 47.7g of 7 groups of distilled water, and add 1.4g of polyacrylamide dropwise with a syringe along the tangential direction during the stirring process, and add 0.9g of water-soluble phenolic resin to each group according to the ratio after stirring evenly.

[0070] (2) Weigh 40g of 7 groups of distilled water, dissolve 3g of starch in 7 groups of boiling water, stir until completely dissolved, then cool to room temperature and add 7g of acrylamide, 0.1g of ammonium persulfate, 0.04g of N, N-methylenebisacrylamide ensures that all pharmaceuticals are co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| ionicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com