Special epoxy resin potting adhesive for ignition coils and preparation method thereof

A technology of epoxy resin and ignition coil, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of high water absorption rate and lower water absorption rate, and achieve excellent heat resistance, excellent electrical performance, and excellent hygroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

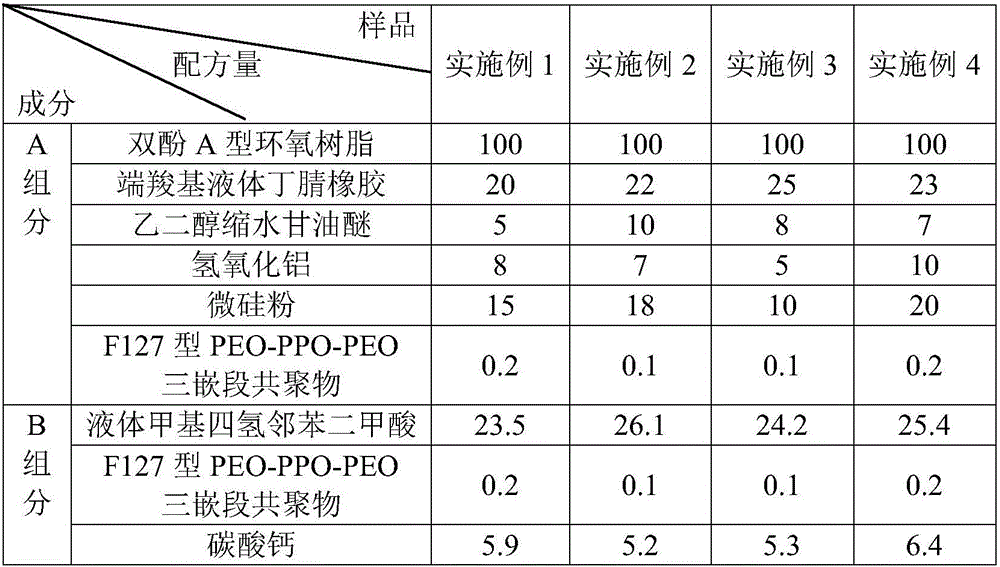

[0032] Embodiment 1-4 is a special epoxy resin potting glue for ignition coil, which is prepared by the following method:

[0033] Step 1, preparation of component A:

[0034] Mix the bisphenol A type epoxy resin, carboxyl-terminated liquid nitrile rubber and ethylene glycol glycidyl ether in the formulated amount, heat up to 130°C and dry for 1-1.5 hours, then add the formulated amount of uniformly dispersed aluminum hydroxide, micro The mixture of silicon powder and F127 type PEO-PPO-PEO tri-block copolymer is stirred and dispersed evenly, and then sand-milled and exhausted in turn to obtain it; the particle size of the obtained component A is 50-100 μm;

[0035] Step 2, preparation of component B:

[0036] Mix the liquid methyltetrahydrophthalic acid in the formula quantity and the PEO-PPO-PEO triblock copolymer of the F127 type, stir and disperse evenly, then gradually add the calcium carbonate in the formula quantity, exhaust gas treatment, and obtain; Particle size of ...

Embodiment 5

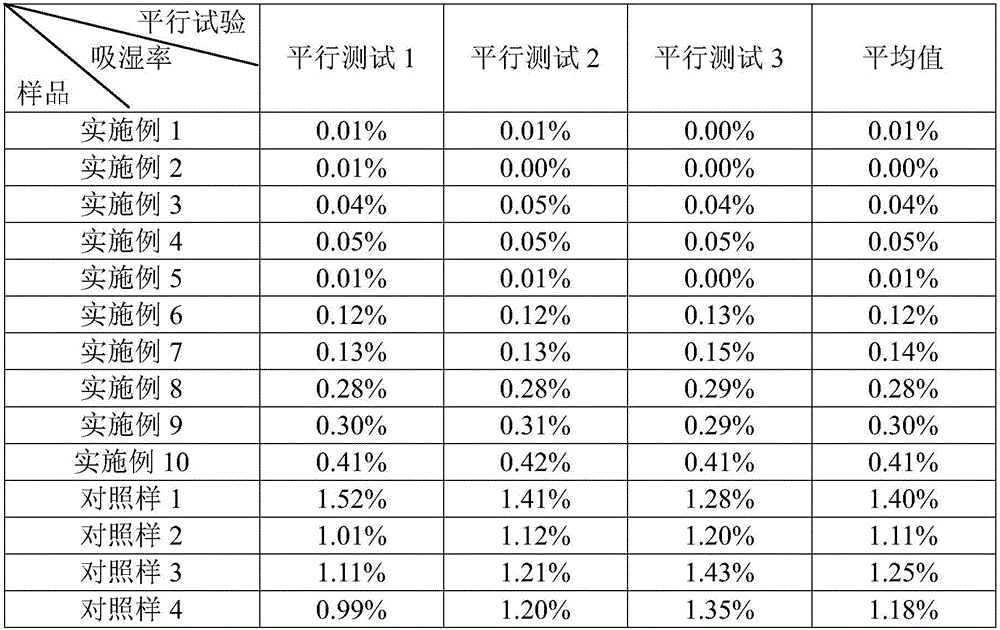

[0041] Embodiment 5 is an epoxy resin potting compound specially used for ignition coils. The difference from Embodiment 1 is that the PEO-PPO-PEO tri-block copolymer is selected as F68 type.

Embodiment 6

[0042] Embodiment 6 is an epoxy resin encapsulant specially used for ignition coils. The difference from Embodiment 1 is that the PEO-PPO-PEO triblock copolymer is of L64 type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com