A method for preparing standard samples of more than ten elements such as as, se, and p in polyvinyl chloride and various phthalates

A technology of phthalates and standard samples, which is applied in the field of preparation of standard samples for analysis, can solve problems such as difficulty in ensuring uniform distribution of elements, digestion of substances that are difficult to add, and inability to implement processing and production, etc., to achieve the goal of manufacturing Uniform sample, easy operation, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] The standard samples that need to be prepared contain target elements, phthalates, and their concentrations as shown in Table 1:

[0051] Table 1

[0052]

[0053] S1, S2. According to the content in Table 1, select the substance in Table 2 as the source of the compound containing the target element, and perform concentration conversion to calculate its addition amount; the formula of the entire high-concentration masterbatch is shown in Table 2:

[0054] Table 2

[0055]

[0056] S3. Use a ball mill to grind the compounds in Table 2, pass through a 200-mesh sieve after grinding, and use a laser particle size analyzer to test the particle size and agglomeration of the compound after grinding to ensure that the compound after grinding will not agglomerate. From the results, it can be seen that the target added substances after grinding meet the production requirements, and no agglomeration occurs. The average particle size of the particles is between 30 and 50 μm...

Embodiment 2

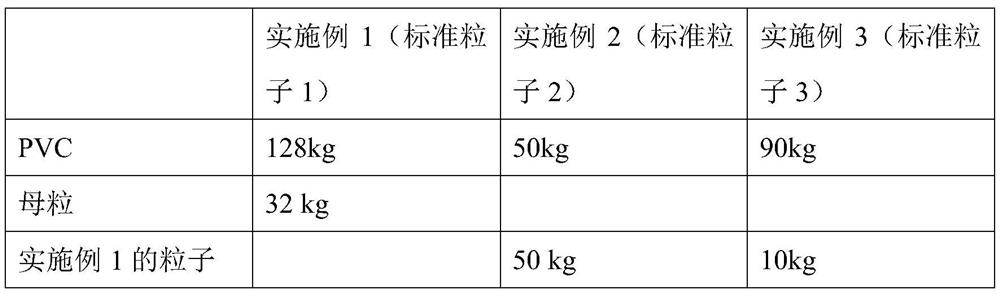

[0064] The preparation method of the standard particle of embodiment 2 and embodiment 3, S1~S7 is identical with embodiment 1, and difference is, after the standard particle that S7 obtains, then according to the amount of table 3, adopt the standard particle that S7 obtains (as high Concentration masterbatch B) is mixed evenly with blank PVC again, and the fifth extrusion granulation is carried out.

[0065] S9. Carry out the sixth extrusion granulation to the particle of the fifth extrusion granulation; And according to the time required for the fifth extrusion granulation, carry out multiple interval sampling during the sixth extrusion granulation , to verify the uniformity between adjacent samples, and complete the preparation after the uniformity is qualified.

Embodiment 3

[0078] Table 7 Example 3 standard sample homogeneity verification

[0079]

[0080] Table 8 Verification of uniformity of prepared masterbatches in comparative examples

[0081]

[0082] It can be seen that if only one granulation is used, even if the uniformity of the small sample is verified during the preparation process, the concentration of the prepared masterbatch will fluctuate greatly between different batches, so this masterbatch is not suitable for standard samples preparation. However, the two-time granulation method of the present invention can well ensure the uniformity between batches.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com