Biological environment-friendly walling material and preparation method thereof

A wall material and bio-environmental protection technology, applied in the field of building materials, can solve the problem of high requirements for raw materials and processes in the manufacture of concrete aerated blocks, large volumes of clay solid bricks and cement hollow blocks, and clay and yellow sand that do not meet the requirements of energy saving and environmental protection. and other problems to achieve the effect of avoiding cracking, excellent physical properties, and reducing forest fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

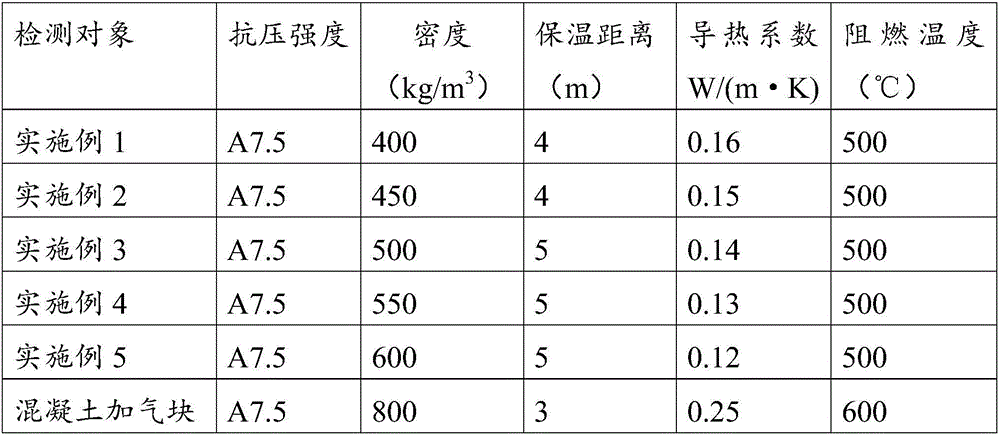

Examples

Embodiment 1

[0038] A bio-environmental protection wall material, made of the following raw materials in parts by weight: 80 parts of main materials, 16 parts of bone glue, and 24 parts of water; the main materials include cement, fine sand, wheat straw, and the cement, fine sand, The mass ratio of wheat straw is 16:8:56.

[0039] A method for preparing the bio-environmental protection wall material, comprising the following steps:

[0040] (1) Rolling the wheat straw into a fibrous shape, then cutting the fibrous wheat straw into a length of 8 cm, and drying until the water content is 10%, to obtain a fibrous material;

[0041] (2) mixing the cement, fine sand, bone glue and water according to the above parts by weight to obtain a slurry;

[0042](3) Stir the fibrous material in the above parts by weight and the slurry evenly, spread it flat, then feed it into a mold, and press it hydraulically for 4 minutes at 180 ° C and 0.8 MPa to obtain a wall blank with a thickness of 6 cm;

[0043...

Embodiment 2

[0045] A bio-environmental protection wall material is made of the following raw materials in parts by weight:

[0046] 90 parts of main ingredients, 18 parts of guar gum, and 27 parts of water; the main ingredients include cement, fine sand, and thatch, and the mass ratio of the cement, fine sand, and thatch is 18:9:63.

[0047] A method for preparing the bio-environmental protection wall material, comprising the following steps:

[0048] (1) Rolling the thatch into a fibrous shape, then cutting the fibrous thatch into a length of 9 cm, and then drying it until the water content is 9%, to obtain a fibrous material;

[0049] (2) mixing the cement, fine sand, guar gum and water according to the above parts by weight to obtain a slurry;

[0050] (3) Stir the fibrous material in the above weight portion with the slurry evenly, spread it flat, then feed it into a mold, and press it hydraulically for 4 minutes at 185° C. and 0.85 MPa to obtain a wall blank with a thickness of 10 c...

Embodiment 3

[0053] A bio-environmental protection wall material is made of the following raw materials in parts by weight:

[0054] 100 parts of main ingredients, 20 parts of stone glue, and 30 parts of water; the main ingredients include cement, fine sand, straw and thatch mixed in equal weight, and the mass of cement, fine sand, straw and thatch mixed in equal weight The ratio is 2:1:7.

[0055] A method for preparing the bio-environmental protection wall material, comprising the following steps:

[0056] (1) Rolling the straw and thatch mixed in equal weight into fibrous form, then cutting the fibrous straw and thatch into a length of 10 cm, and then drying until the water content is 8%, to obtain a fibrous material;

[0057] (2) mixing the cement, fine sand, stone glue and water according to the above parts by weight to obtain a slurry;

[0058] (3) Stir the fibrous material in the above parts by weight and the slurry evenly, spread it flat, then feed it into a mold, and press it hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com