Variable gap type fiber bundle filter and application method thereof

A fiber bundle and filter technology, applied in the field of variable gap fiber bundle filters, can solve the problems of difficult removal of suspended solids in water, slow filtration flow rate, low filtration precision, etc., achieve low cost, reduce side flow degree, and improve filtration effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

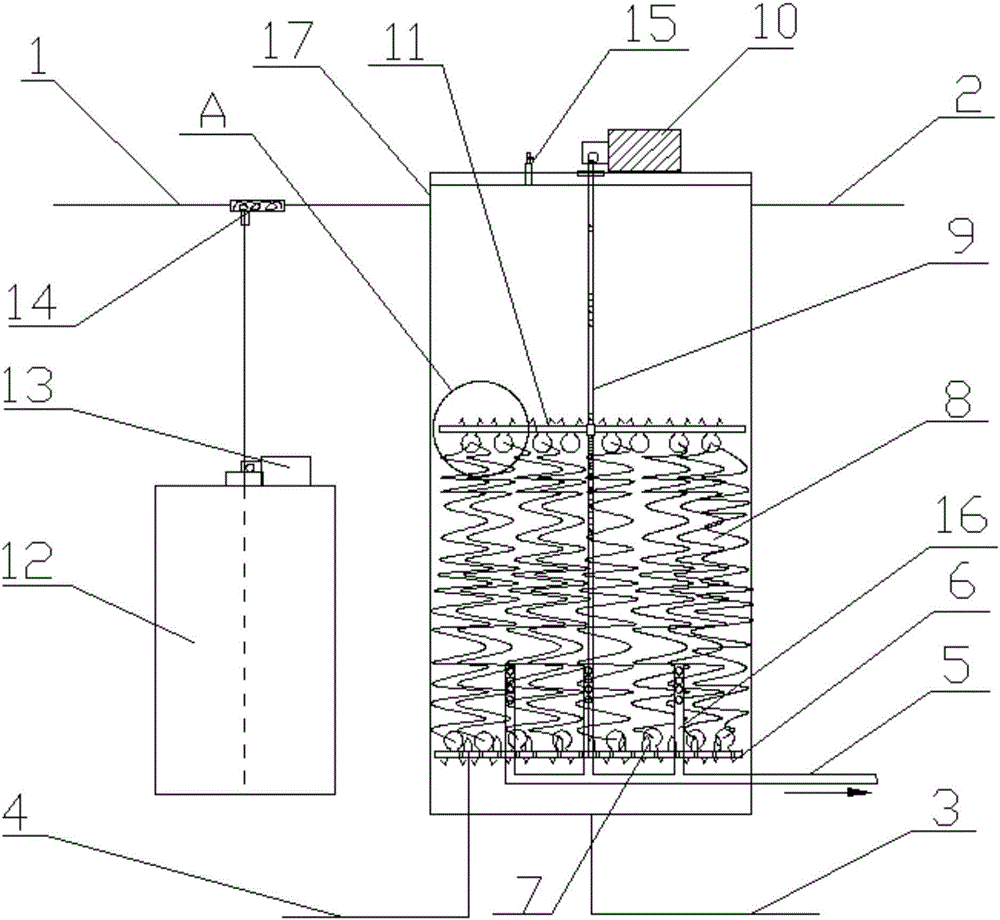

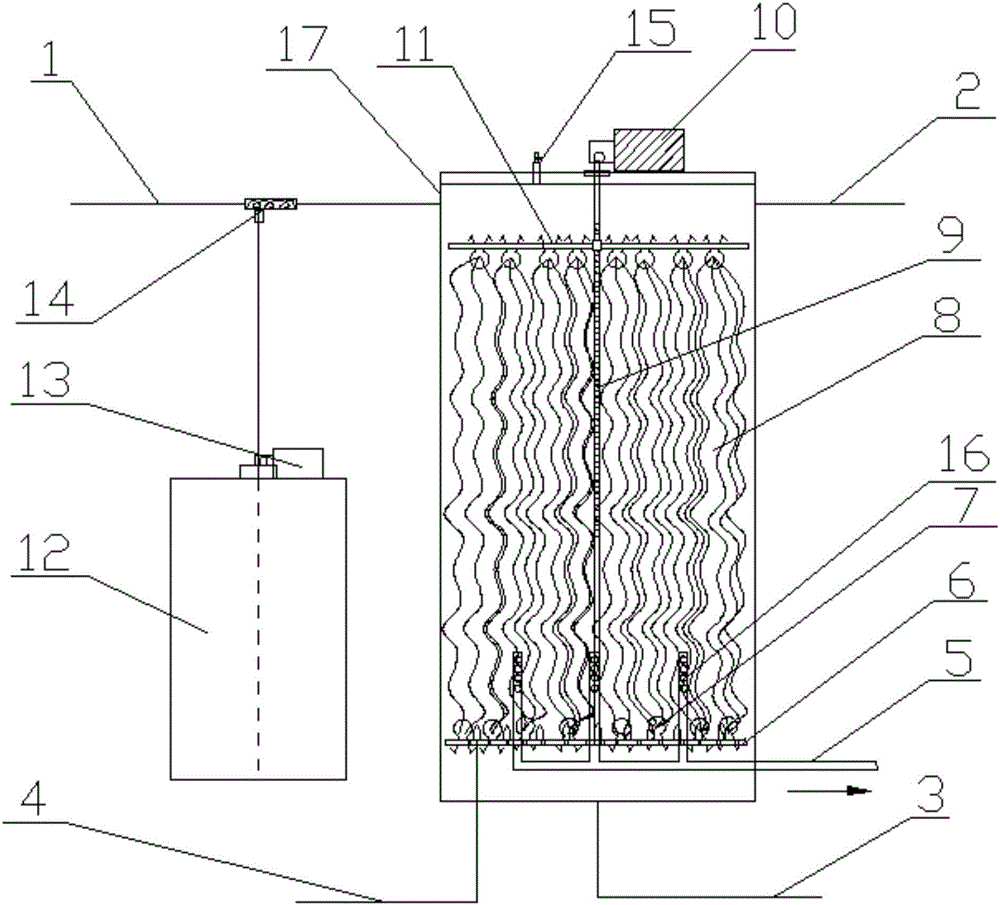

[0064] Embodiment one: if image 3 As shown, the flocculation device is a flocculant adding device. The flocculant adding device includes a pipeline mixer 14, a dosing box 12 and a metering pump 13. The pipeline mixer 14 is installed on the filter inlet pipe 1, and the metering pump 13 is installed on the On the dosing box 12 , the flocculant in the dosing box 12 is transported to the inline mixer 14 through the operation of the metering pump 13 and fully mixed with the water source to be filtered in the filtered water inlet pipe 1 . The amount of flocculant added is controlled by the metering pump 13 to avoid wasting the dosage and improve the flocculation effect. By adding the flocculant in advance to the water source to be filtered, the impurities in the water source can be flocculated and the filtration effect is improved.

Embodiment 2

[0065] Embodiment two: if Figure 4 As mentioned above, the flocculation device is an electrocoagulation device, and the electrocoagulation device includes a box body 22. The water outlet end of the box body 22 is connected to the filter water inlet pipe 1, and the filter water inlet pipe 1 is provided with a raw water pump 19. In order to ensure that the raw water pump 19 sucks strength, the casing 22 is a sealed structure. The box body 22 is provided with a central shaft 21, and the box body 22 is provided with a motor 20 that drives the central shaft 21 to rotate. The motor 20 is a micro motor, which is small in size and takes up little space, but can provide enough power to drive the central shaft 21. turn. The central shaft 21 is spirally wound with auger blades 24 along its axial direction, and the auger blades 23 can be helically fixed on the central shaft 21 by welding, or the auger blades 23 and the central shaft 21 are integrally formed. The box body 22 is provided...

Embodiment 3

[0066] Embodiment three: as Figure 5 As shown, the flocculation device is an electrocoagulation device, and the electrocoagulation device includes a cylinder 25, which is provided with a positive electrode net 26 concentric with the cylinder 25, and a negative electrode is arranged between the cylinder 25 and the positive electrode net 26. net 27, and the negative electrode net 27 and the positive electrode net 26 are concentrically arranged, the filter water inlet pipe 1 stretches into the center of the cylinder 25, the outside of the cylinder 25 is provided with a driving motor 28 that drives the positive electrode net 26 to rotate, and the bottom of the cylinder 25 is provided with Drainage pipe 29 is arranged, is convenient to fully drain surplus water. The positive electrode net 26 and the negative electrode net 27 both adopt a cylindrical structure, and the ends can adopt a closed structure, so that the water source must pass through the electric field formed by the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com