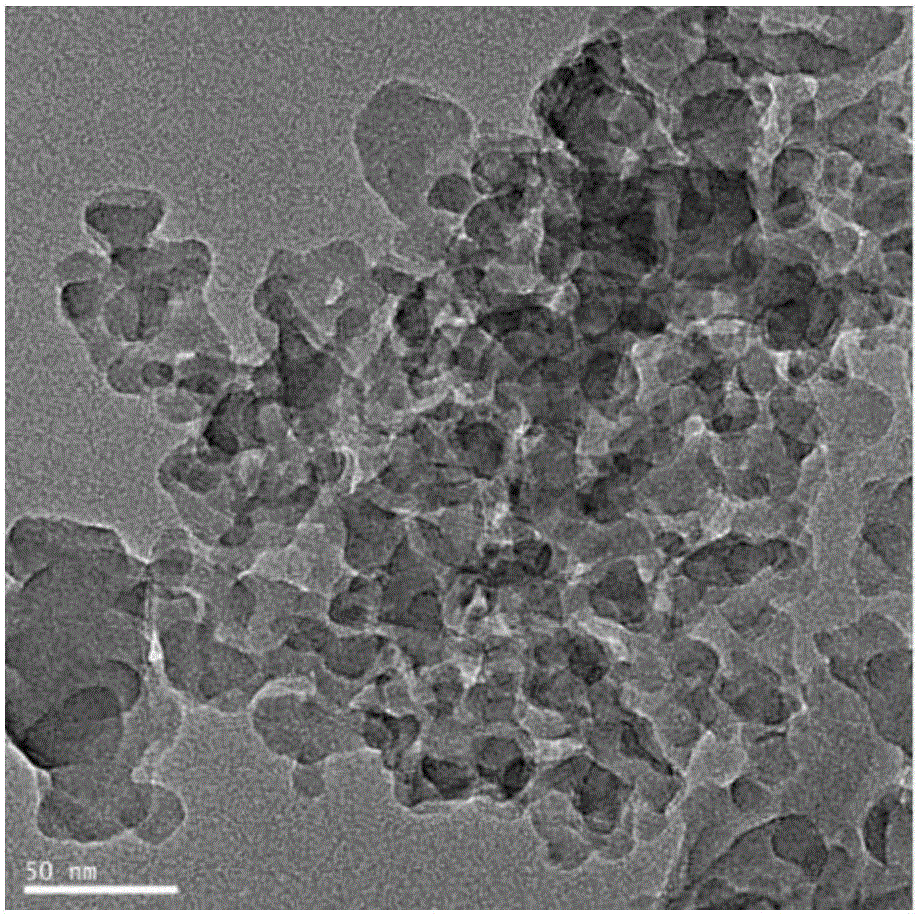

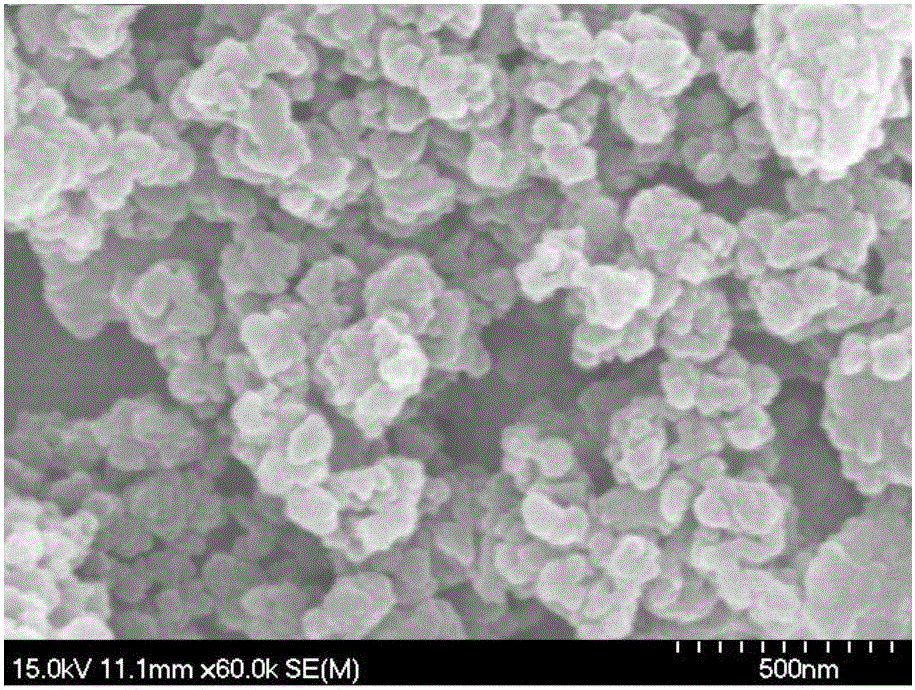

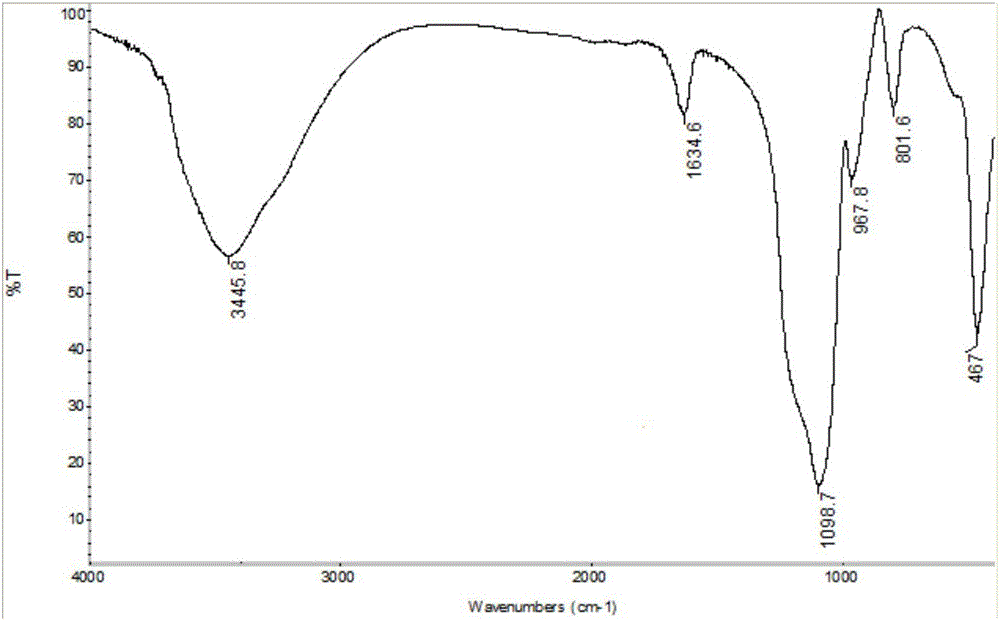

Supergravity gas-liquid precipitation method for preparing silica nanoparticles based on rice hull ash

A silicon dioxide and nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of low product quality, large product particle size, low activity, etc., and achieve the production cycle The effect of shortening, increasing conversion rates, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 100g of crushed rice husk ash and place it in a 1L three-necked flask, and pour 1L of 1mol / L hydrochloric acid solution into 1L of 1mol / L hydrochloric acid solution according to the amount of acid solution added based on the mass of the rice husk ash, and put condensing reflux on the three-necked flask device, placed in boiling water for 2h. Immediately after the reaction was completed, filter and wash with deionized water until the washing was neutral. Take the filter residue and dry it at 120°C to obtain the treated rice husk ash for future use.

[0032] (2) Weigh 30g of treated rice husk ash and place it in a 500mL three-necked flask, and pour 150ml of 2.5mol / L Na 2 CO 3 solution, install a condensing reflux device on the three-neck flask, and place it in boiling water for 4 hours. Immediately after the reaction, filter, wash with 150mL 85°C deionized water, combine the filtrates to form a water glass solution, keep it warm, and reserve it for the acidif...

Embodiment 2

[0037] (1) Weigh 100g of crushed rice husk ash and place it in a 1L three-necked flask, and pour 1L of 1mol / L hydrochloric acid solution into 1L of 1mol / L hydrochloric acid solution according to the amount of acid solution added based on the mass of the rice husk ash, and put condensing reflux on the three-necked flask device, placed in boiling water for 2h. Immediately after the reaction was completed, filter and wash with deionized water until the washing was neutral. Take the filter residue and dry it at 120°C to obtain the treated rice husk ash for future use.

[0038] (2) Weigh 30g of treated rice husk ash and place it in a 500mL three-necked flask, and pour 10mL / g into 300mL 1.5mol / L Na 2 CO 3 solution, install a condensing reflux device on a three-necked flask, and place it in boiling water for 3 hours. Immediately after the reaction, filter and wash with 300mL 95°C deionized water, combine the filtrate, keep it warm, and save it for the acidification precipitation m...

Embodiment 3

[0041] (1) Weigh 100g of pulverized rice husk ash and place it in a 1L three-necked flask, pour 500mL of 5mol / L hydrochloric acid solution into 500mL of 5mol / L hydrochloric acid solution according to the amount of acid solution added in terms of rice husk ash mass, and put condensing reflux on the three-necked flask device, placed in boiling water for 1h. Immediately after the reaction was completed, filter and wash with deionized water until the washing was neutral. Take the filter residue and dry it at 120°C to obtain the treated rice husk ash for future use.

[0042] (2) Weigh 30g of processed rice husk ash and place it in a 500mL three-necked flask, and pour 15mL / g into 450mL 0.1mol / L NaOH solution according to the amount of alkaline solution added in terms of the mass of the solid product, and put condensate on the three-necked flask Reflux device, placed in boiling water for 5h. Immediately after the reaction, filter and wash with 450mL 90°C deionized water, combine th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com