Preparation device of graphene composite dispersion liquid

A graphene composite and preparation device technology, applied in the directions of carbon compounds, inorganic chemistry, non-metallic elements, etc., to reduce labor intensity, be easy to popularize and use, and improve preparation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

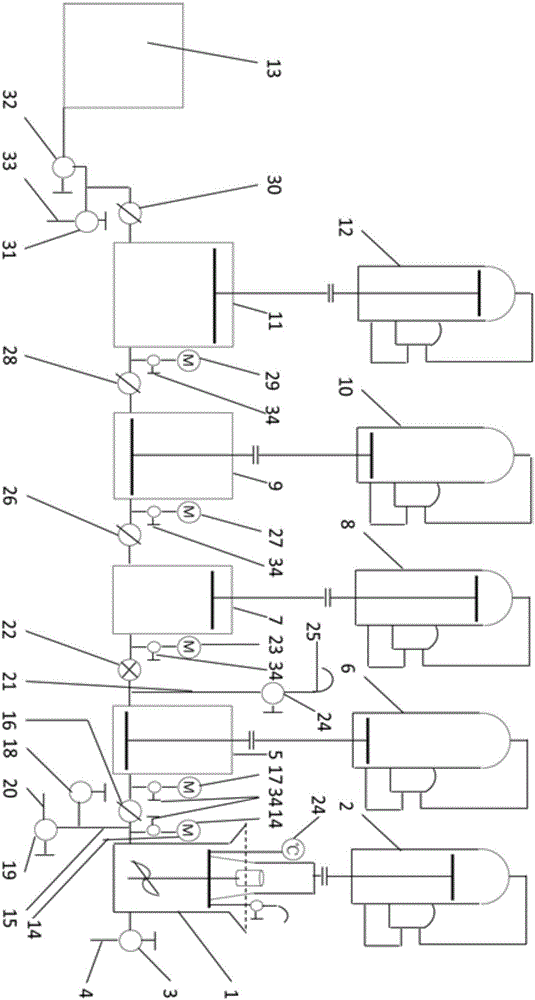

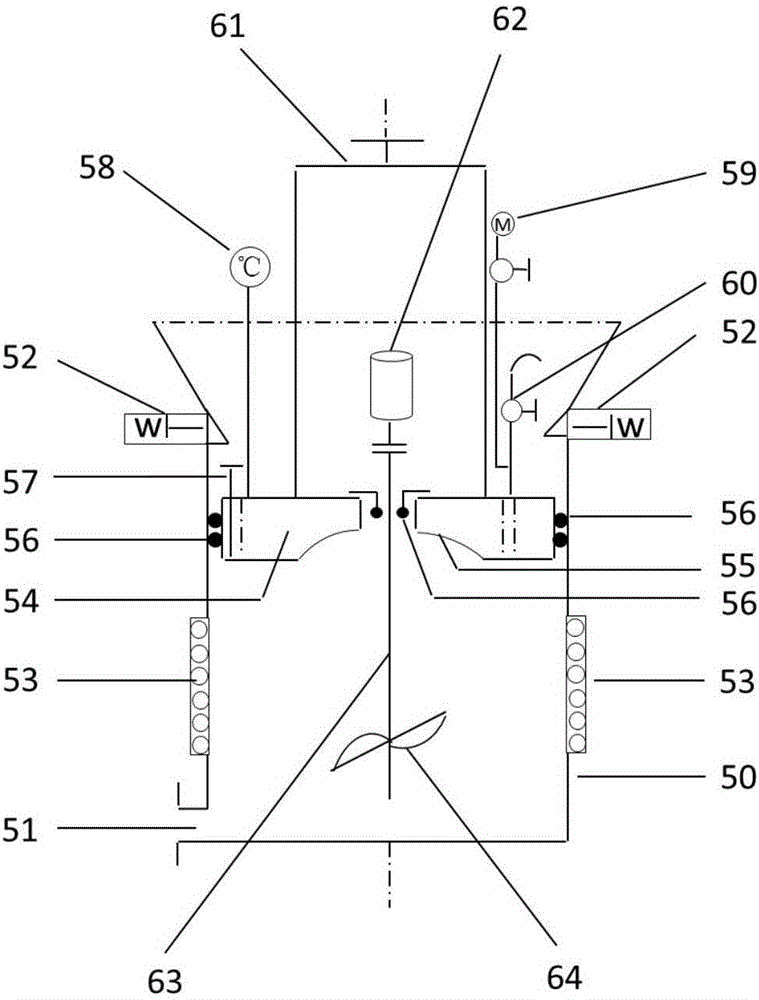

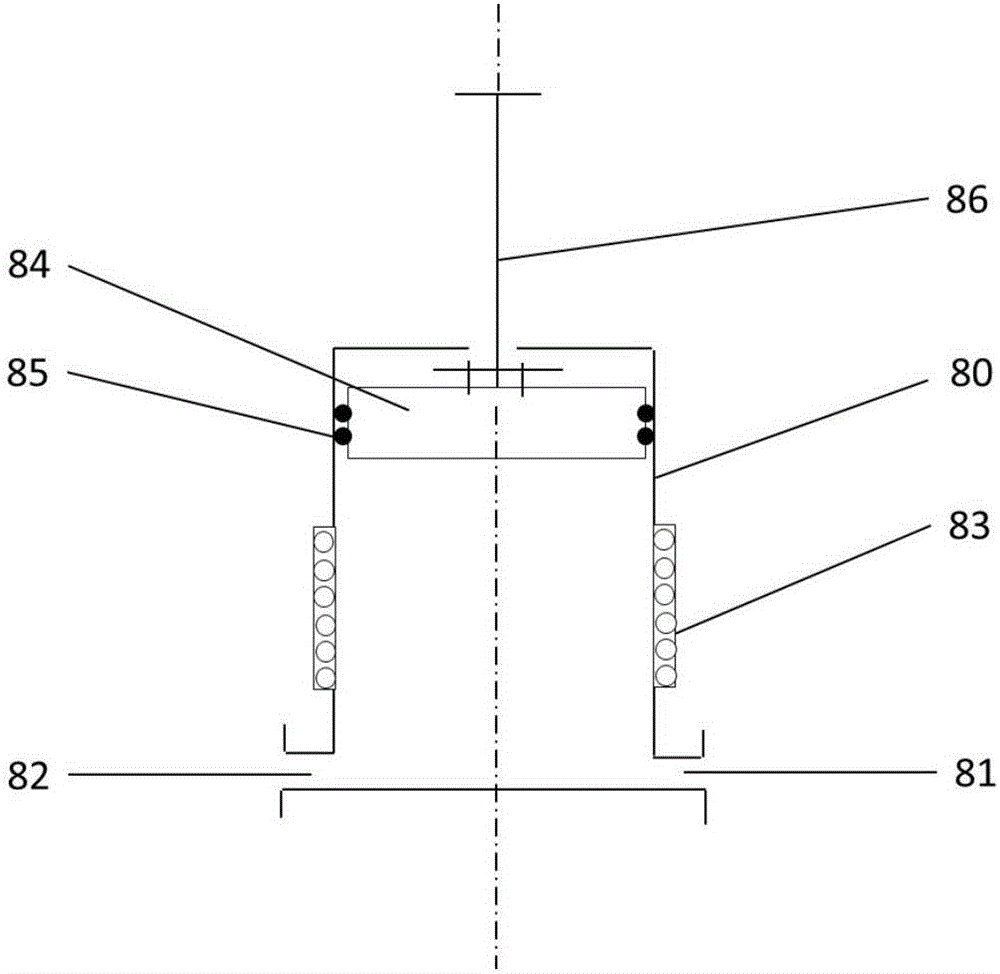

[0025] The main structure of the graphene composite dispersion liquid preparation device involved in this embodiment includes a reaction kettle 1, a No. 1 electro-hydraulic servo mechanism 2, a No. 1 sampling valve 3, a No. 1 sampling port 4, a No. Hydraulic servo mechanism 6, No. 2 pressure cylinder 7, No. 3 electro-hydraulic servo mechanism 8, No. 1 decompression cylinder 9, No. 4 electro-hydraulic servo mechanism 10, No. 2 decompression cylinder 11, No. 5 electro-hydraulic servo mechanism 12, Storage container 13, No. 1 pressure gauge 14, No. 1 branch pipe 15, No. 1 one-way jet valve 16, No. 2 pressure gauge 17, safety valve 18, liquid filling valve 19, liquid filling port 20, No. 2 branch pipe 21, Two-way jet valve 22, No. 3 pressure gauge 23, No. 2 sampling valve 24, No. 2 sampling port 25, No. 2 one-way jet valve 26, No. 4 pressure gauge 27, No. 3 one-way jet valve 28, No. 5 pressure gauge 29 , No. 4 one-way jet valve 30, No. 3 sampling valve 31, discharge valve 32, No. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com