Multifunctional filling machine and filling method thereof

A filling machine, multi-functional technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of increasing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

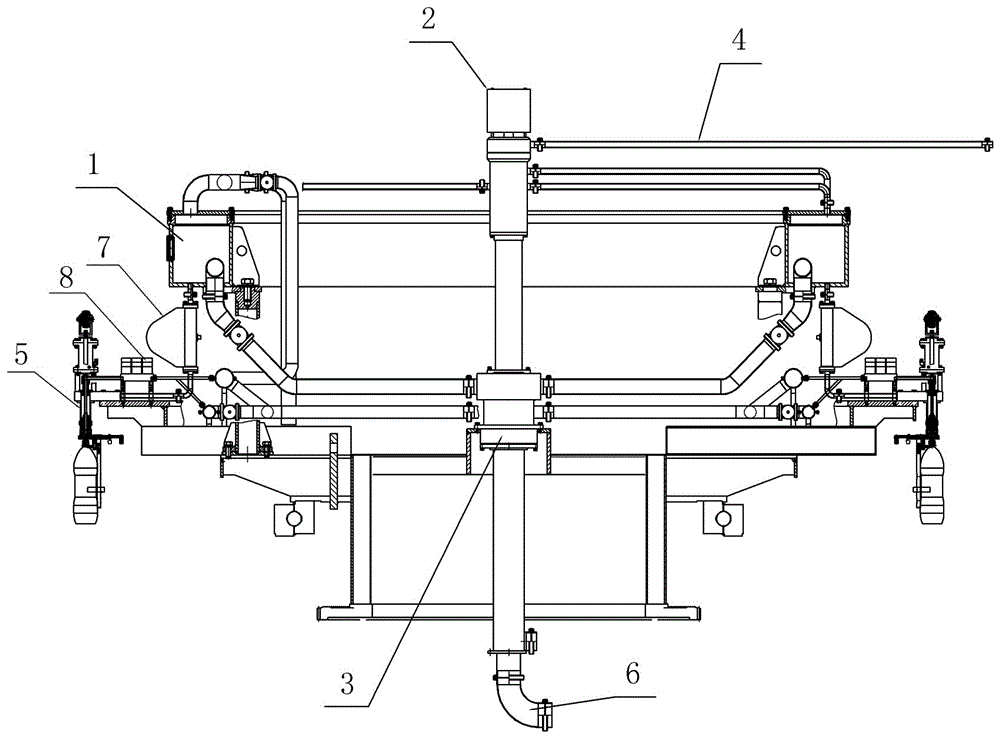

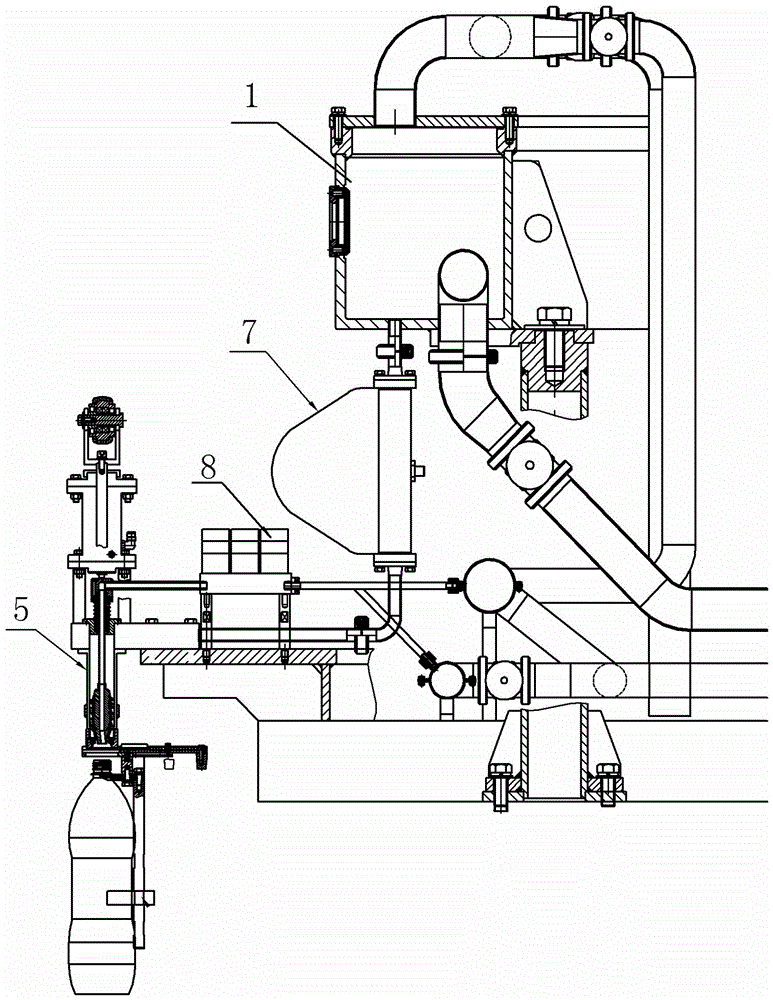

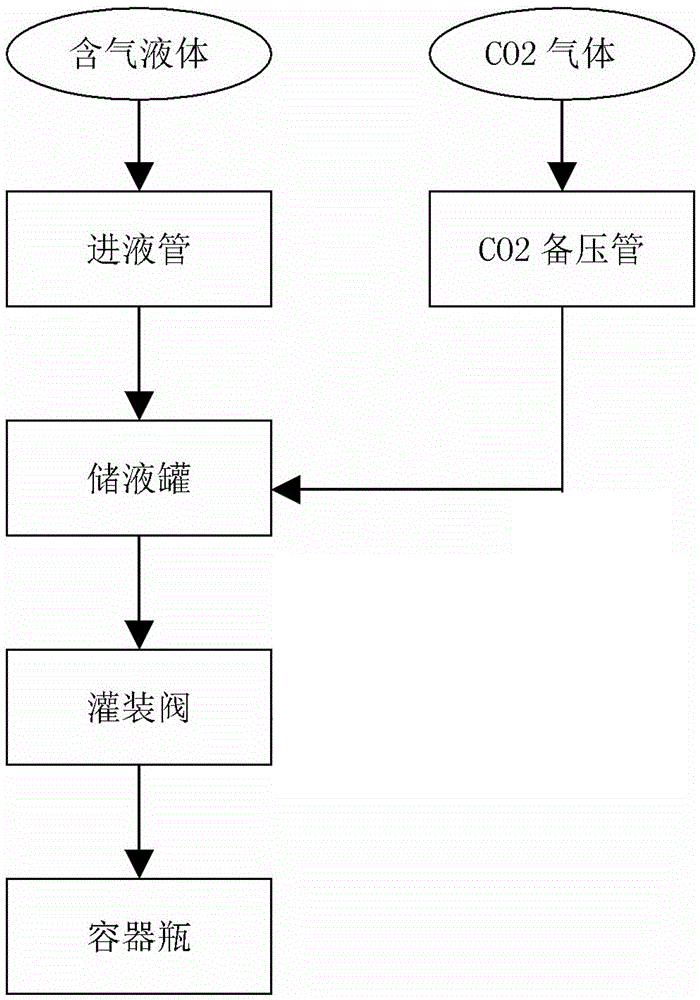

[0013] Such as figure 1 As shown, a multifunctional filling machine includes a liquid storage tank 1 for storing liquid, an upper distributor 2 and a lower distributor 3 for controlling the conveying channel, a CO2 backup pressure tube 4 for inputting carbon dioxide gas, and a container for filling The filling valve 5, the liquid inlet pipe 6 where the liquid enters and the return pipe with the switch valve; the upper distributor is respectively connected with the liquid storage tank and the CO2 backup pressure pipe through the pipeline, and the lower distributor is respectively connected with the liquid storage and filling The valve and the liquid inlet pipe, also, the liquid storage tank and the lower distributor are also connected through the return pipe, and the bottom and top of the liquid storage tank are respectively connected to the filling valve through the pipeline; several proportional valves are installed on the CO2 backup pressure pipe. valve. The CO2 backup pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com