AMT clutch actuating mechanism for diesel fork lift truck

A technology for actuators and internal combustion forklifts, applied to clutches, mechanical equipment, lifting devices, etc., can solve problems such as difficult maintenance, complex transmission structure, and high technical requirements, and achieve reasonable design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

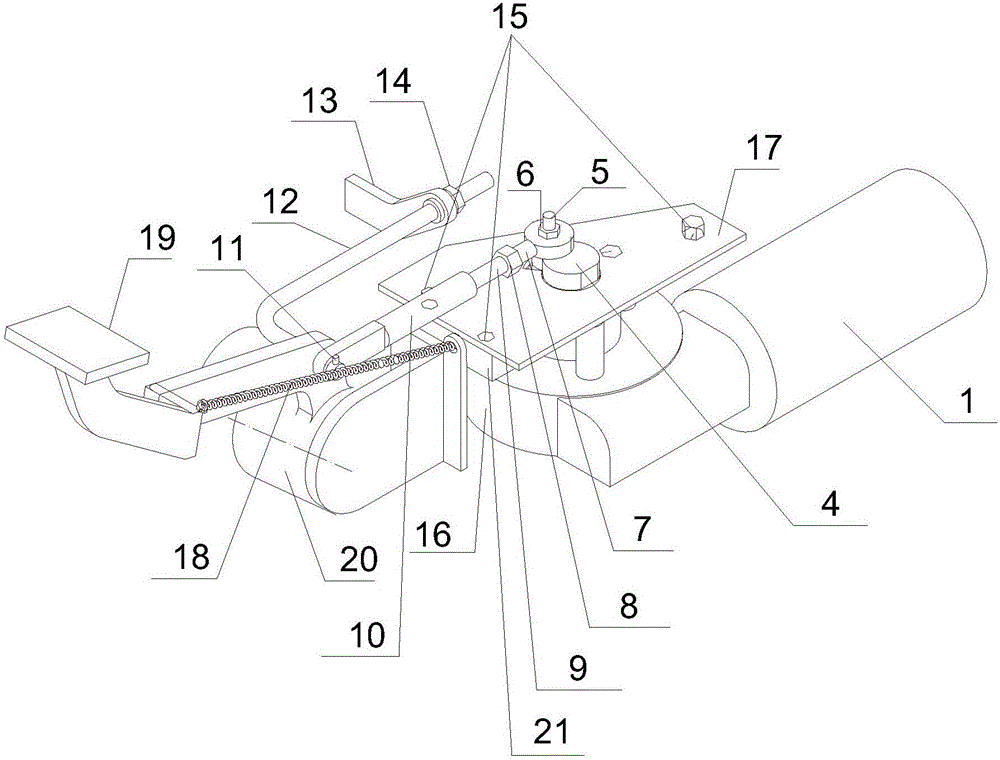

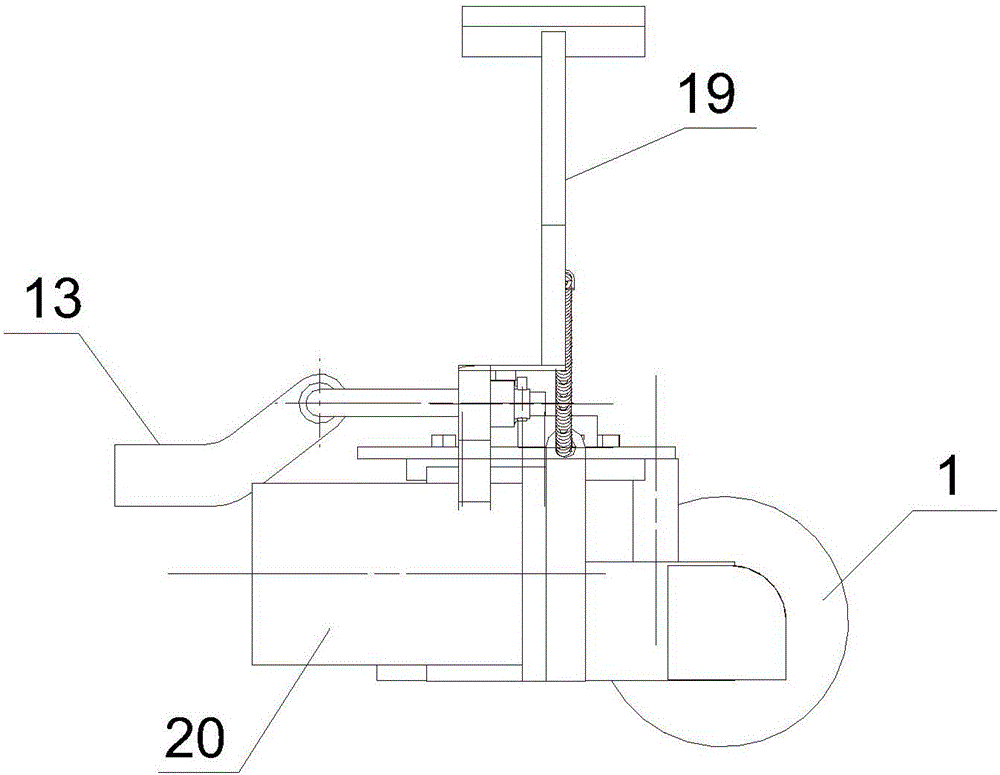

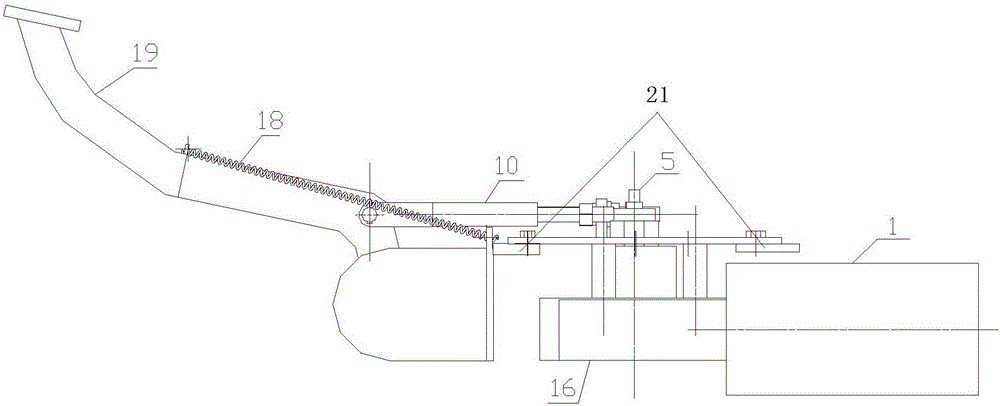

[0027] see Figure 1-6 , an AMT clutch actuator for an internal combustion forklift, comprising a motor 1, a worm gear mechanism, an eccentric wheel 4, a power output rod and a sliding rod mechanism, a connecting rod and a clutch fork mechanism, and a fixed connection plate 17;

[0028] The worm gear mechanism includes a worm gear housing 16, a worm 2, a turbine 3 and a turbine rotating shaft 24; the motor output shaft 22 of the motor 1 passes through the worm gear housing 16, and the motor output shaft 22 is movably connected with the worm gear housing 16, and The motor output shaft 22 is fixedly connected to the worm 2 through a coupling 23, the worm 2 is externally engaged with the turbine 3, and the turbine 3 is fixedly connected to the turbine shaft 24 through a key 25, both the worm 2 and the turbine 3 are located inside the worm casing 16, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com