Garbage conveying device

A garbage transportation and garbage technology, applied in the field of garbage collection, can solve the problems of poor air circulation, stagnation, and unfavorable operation efficiency of suction transfer equipment, and achieve the effect of reducing frictional resistance and improving suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

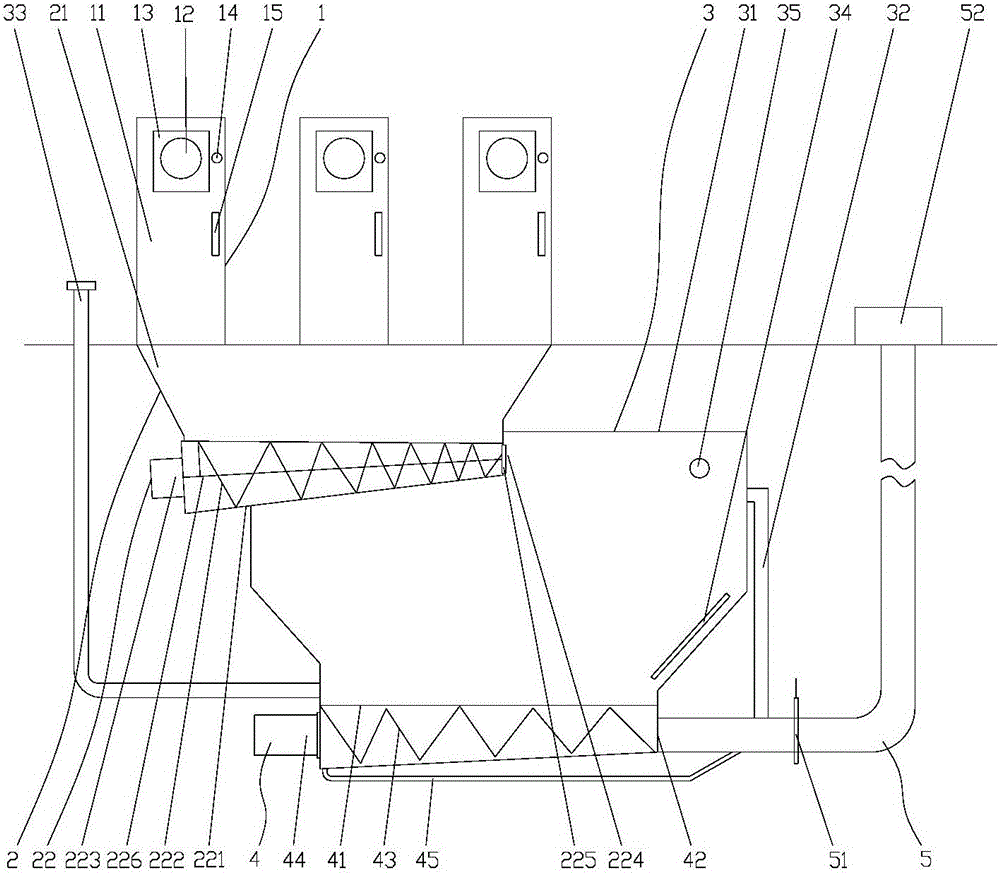

[0044] Such as figure 1 As shown, the garbage temporary storage and crushing mechanism 2 includes a garbage temporary storage bucket 21, the top of the garbage temporary storage bucket 21 is respectively connected with several garbage dispensing mechanisms 1, and the bottom of the garbage temporary storage bucket 21 is provided with a bucket for crushing and transporting garbage. To the screw crushing mechanism 22 in the garbage storage mechanism 3.

[0045] The spiral crushing mechanism 22 includes a variable-section spiral groove 221, and the top of the variable-section spiral groove 221 communicates with the garbage temporary storage bucket 21. At least one variable-pitch variable-diameter spiral blade 222 is arranged in the variable-section spiral groove 221. The diameter spiral blade 222 is driven to rotate by the second driver 223. One end of the variable cross-section spiral groove 221 is provided with a discharge port 224 communicating with the garbage storage mechanis...

Embodiment 2

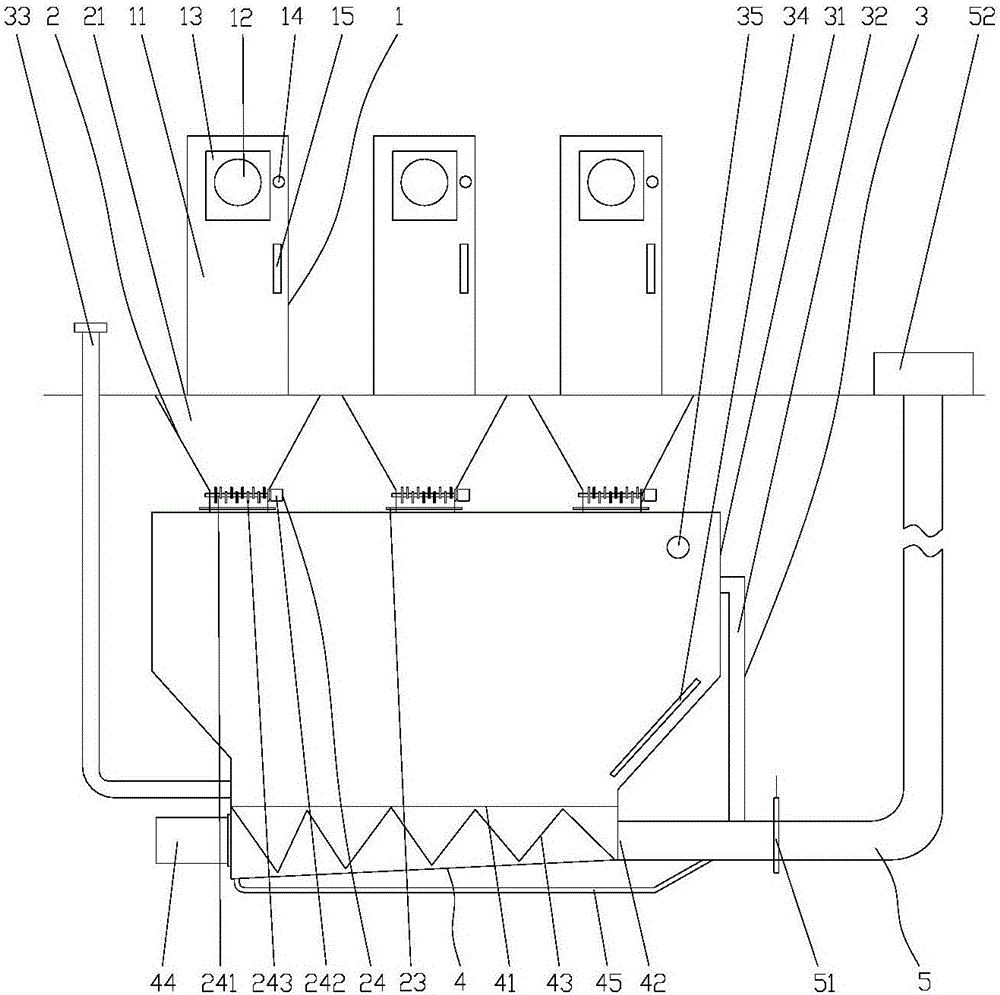

[0049] Such as figure 2 or image 3 As shown, the garbage temporary storage and crushing mechanism 2 includes several garbage temporary storage buckets 21, the tops of the several garbage temporary storage buckets 21 are respectively connected with several garbage delivery mechanisms 1, and the bottoms of the several garbage temporary storage buckets 21 are respectively connected to each other. Through the feeding valve 23, it communicates with the garbage storage mechanism 3, and a bag breaking mechanism 24 for breaking oversized garbage and garbage bags is provided in several temporary garbage storage buckets 21.

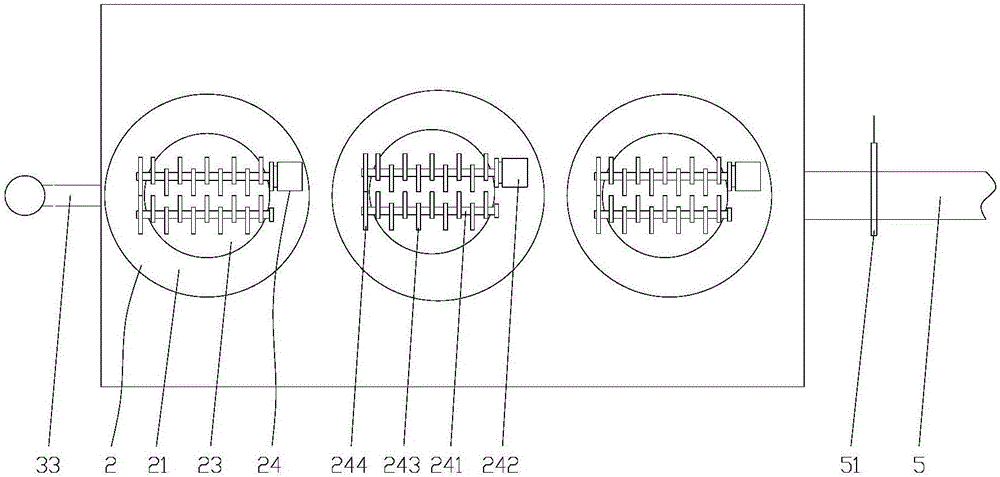

[0050] The bag breaking mechanism 24 includes at least one rotating shaft 241 , each rotating shaft 241 is driven to rotate by a first driver 242 , and each rotating shaft 241 is provided with several bag breaking knives 243 .

[0051] Such as image 3 As shown, the bag breaking mechanism 24 includes two rotating shafts 241 , and the two rotating shafts 241 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com