Automatic feeding type cutting and labelling mechanism

A technology of automatic feeding and racking, which is applied in labeling machines, labels, thin material processing, etc., can solve the problems of unreusable and wasteful release paper, and achieve the effect of high paste efficiency, waste reduction and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

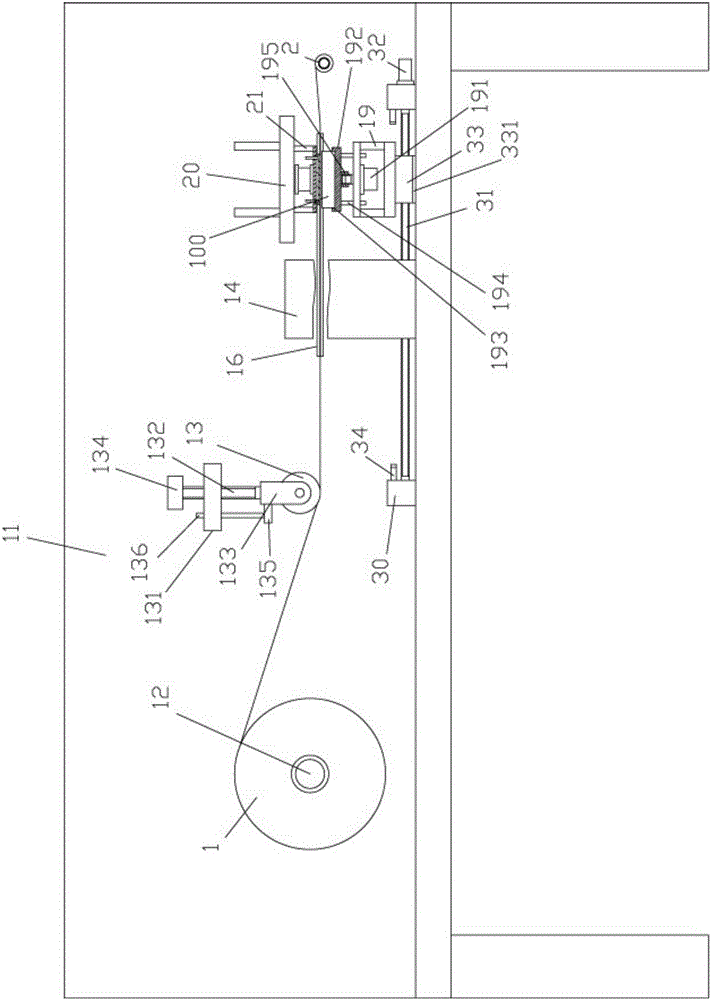

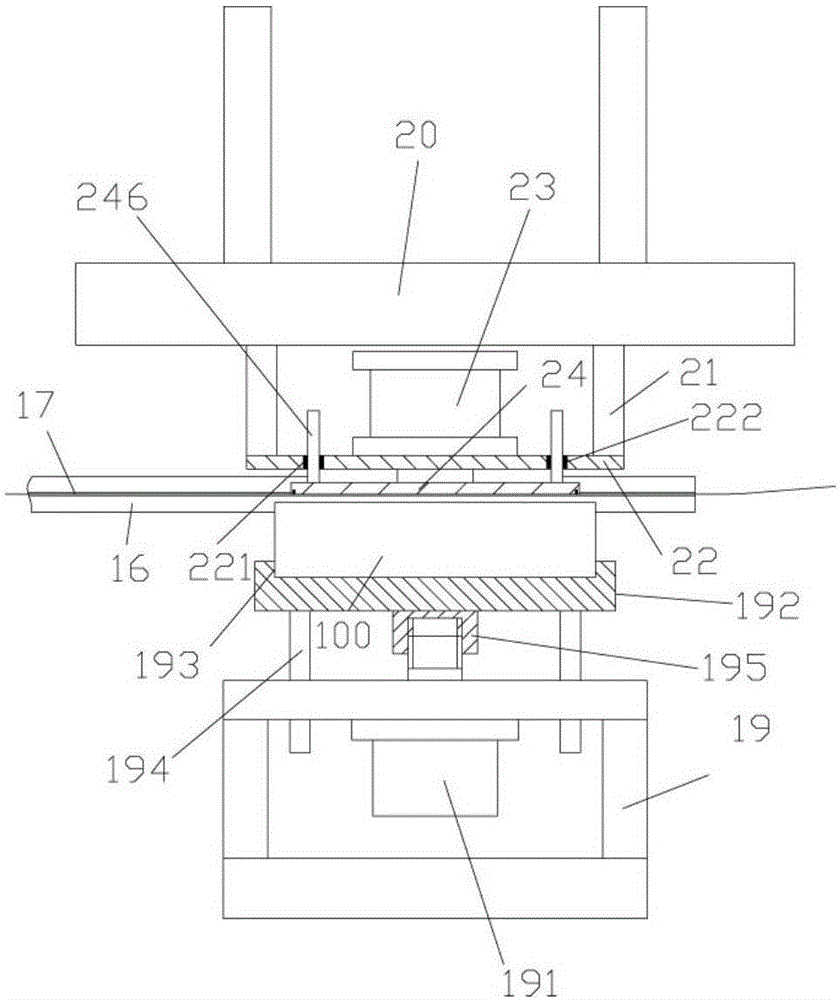

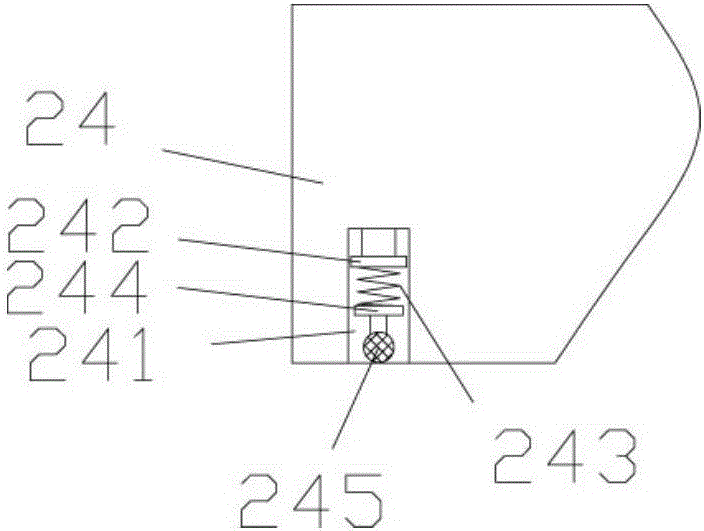

[0026] Examples, see e.g. Figure 1 to Figure 6 As shown, an automatic feeding type cutting and labeling mechanism includes a frame 10, a main support plate 11 is fixed on the top surface of the rear side of the top plate of the frame 10, and a main support plate 11 is hinged on the left front wall of the main support plate 11. Rotating shaft 12, the label reel 1 is installed on the main rotating shaft 12, the front wall surface of the main supporting plate 11 on the right side of the main rotating shaft 12 is fixed with an adjusting plate 131, the adjusting plate 131 is screwed with an adjusting screw rod 132, the adjusting screw rod 132 The lower end of the tension roller 13 is hinged on the roller body connecting frame 133, and the tensioning roller 13 is hinged in the roller body connecting frame 133. The lower end of the tensioning roller 13 protrudes from the roller body connecting frame 133, and the top end of the adjusting screw 132 is fixed with a rotating part 134. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com