Transparent case matte three-dimensional effect treatment process and product

A technology of three-dimensional effect and transparent shell, which is applied in the field of matte three-dimensional effect processing technology and products of transparent shell, can solve the problems such as the inability to retain the transparent or translucent characteristics of glass or plastic shell, and the inability to form a matte three-dimensional effect, etc. To achieve the effect of scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

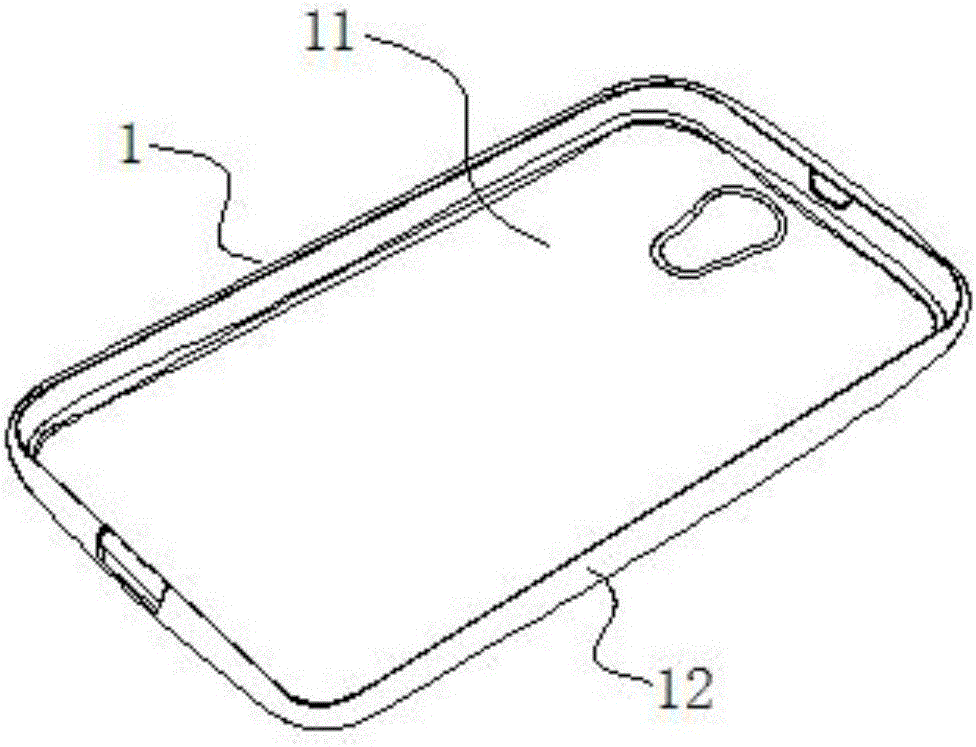

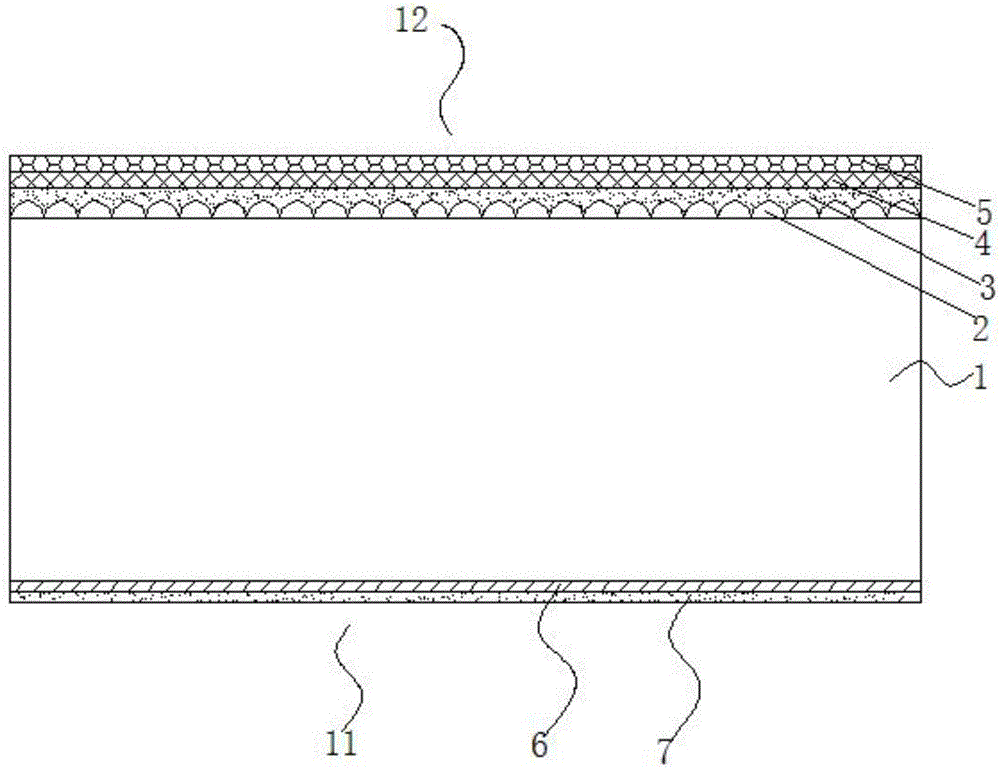

[0025] see Figures 1 to 2 , the transparent shell matte three-dimensional effect treatment process provided by this embodiment includes the following steps:

[0026] 1) Laser cutting of transparent materials: use laser cutting equipment to cut transparent glass or plastic, obtain shell substrate parts with preset sizes, and distinguish the front side 11 and back side 12 of the shell 1;

[0027] 2) Reverse surface 12 sandblasting, radium carving, stone engraving into a matte surface: use quartz sand to perform sandblasting on the reverse surface of transparent glass or plastic shell substrates, so that the surface forms a translucent matte matte effect The frosted layer is then treated with radium engraving and stone engraving, so that the surface forms a matte surface layer 2 with radium engraving and etching patterns; among them, the silica content of quartz sand is ≥ 95%, and the particle size range is 0.3~0.8mm. It is carried out under the dry condition of quartz sand tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com