Polyvinyl chloride floor resistant to stain and easy to clean as well as preparation process of polyvinyl chloride floor

A polyvinyl chloride, easy-to-clean technology, applied in the direction of ester copolymer adhesive, adhesive type, lamination, etc., can solve the limited application range of polyvinyl chloride floor, chemical reagents are easy to stain and leave traces, organic volatilization To avoid problems such as excessive gas, to achieve the effects of inhibiting bacterial reproduction, excellent weather resistance, and strong killing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

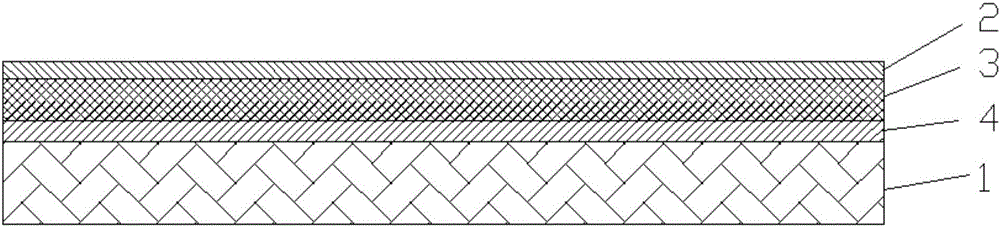

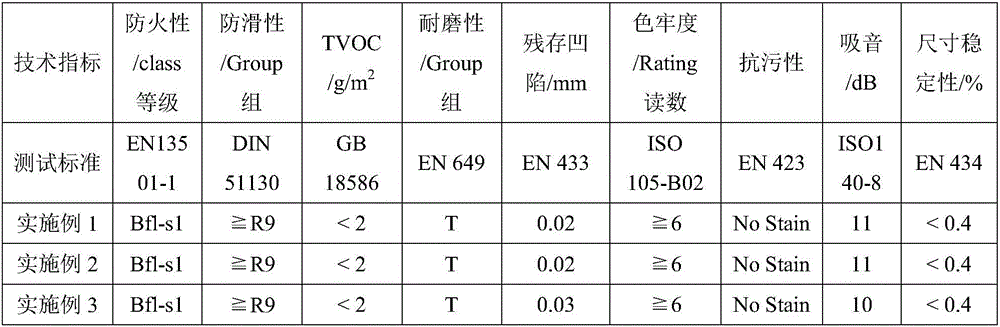

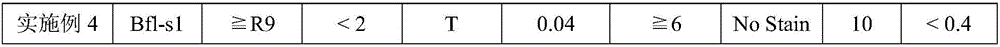

[0025] Depend on figure 1 As shown, a polyvinyl chloride floor with high stain resistance and easy cleaning function in this embodiment includes a composite dense polyvinyl chloride floor layer 1 and an antifouling surface layer with a thickness ratio of 40:1, and the antifouling surface layer is composed of The outer protective layer 2, the functional layer 3 and the adhesive layer 4 are co-extruded with a thickness ratio of 1:3:1. The outer protective layer 2 is a fluorine-containing high polymer polyvinylidene fluoride and polytetrafluoroethylene with a ratio of 100:3. The functional layer 3 is made by mixing polyvinylidene fluoride, modified polyacrylic resin and UV absorber in a ratio of 80:20:0.5, and the adhesive layer 4 is made of polyvinylidene fluoride and modified polyvinylidene fluoride. The acrylic resin is mixed in a ratio of 20:80; the anti-fouling surface layer is connected with the composite compact polyvinyl chloride floor layer 1 by hot-melt bonding through ...

Embodiment 2

[0028] Depend on figure 1 As shown, a kind of polyvinyl chloride floor with high anti-fouling and easy-cleaning function of the present embodiment includes a composite foamed polyvinyl chloride floor layer 1 and an anti-fouling surface layer with a thickness ratio of 40:1, and the anti-fouling surface layer It is co-extruded from the outer protective layer 2, functional layer 3 and adhesive layer 4 with a thickness ratio of 1:3:1. The outer protective layer 2 is polyvinylidene fluoride, a high polymer containing fluorine, and the functional layer 3 is polyvinylidene fluoride. Ethylene and UV absorber are mixed at a ratio of 100:0.5, and the bonding layer 4 is made of polyvinylidene fluoride and modified polyacrylic resin at a ratio of 10:90; the antifouling surface layer passes through the bonding layer One side of 4 is connected with composite foamed polyvinyl chloride floor layer 1 by heat-melt bonding.

[0029] A preparation process for a polyvinyl chloride floor with a hi...

Embodiment 3

[0031] Depend on figure 1 As shown, a polyvinyl chloride floor with high stain resistance and easy-cleaning function in this embodiment includes a homogeneous core-penetrating polyvinyl chloride floor layer 1 and an antifouling surface layer with a thickness ratio of 40:1, and the antifouling surface The outer protective layer 2, the functional layer 3 and the adhesive layer 4 are co-extruded with a thickness ratio of 1:3:1. The outer protective layer 2 is a fluorine-containing high polymer polyvinylidene fluoride and polytetrafluoroethylene with a thickness of 100 : 3, the functional layer 3 is polyvinylidene fluoride, modified polyacrylic resin and UV absorber in a ratio of 20:80:0.5, and the bonding layer 4 is polyvinylidene fluoride and modified It is formed by mixing permanent polyacrylic resin in a ratio of 20:80; the anti-fouling surface layer is connected with the homogeneous core-penetrating polyvinyl chloride floor layer 1 by hot-melt bonding through one side of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com