Large-capacity exhaust ink bag for large-width ink-jet printer

A technology for exhausting ink sacs and printers, applied in printing and other directions, can solve the problem of increasing the probability of ink failure in printers, and achieve the effects of extending the continuous working time, increasing the diameter, and isolating volatilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

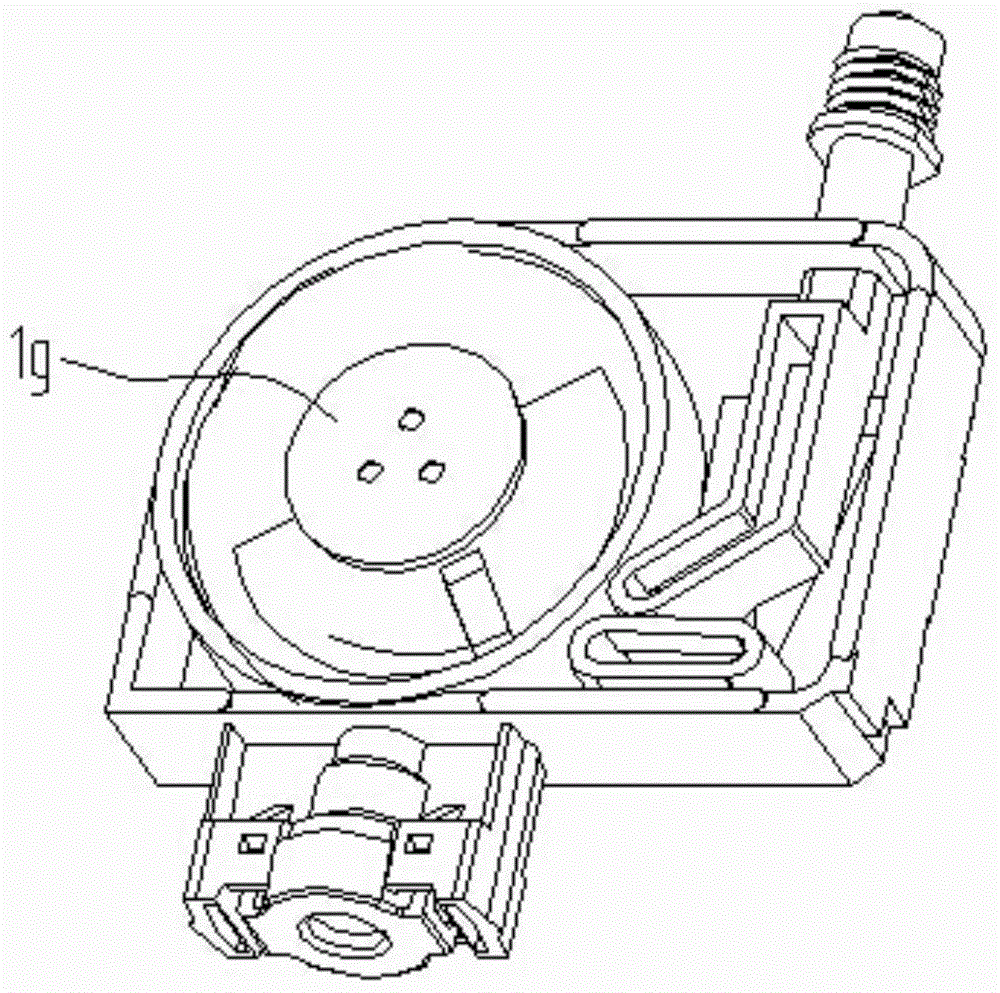

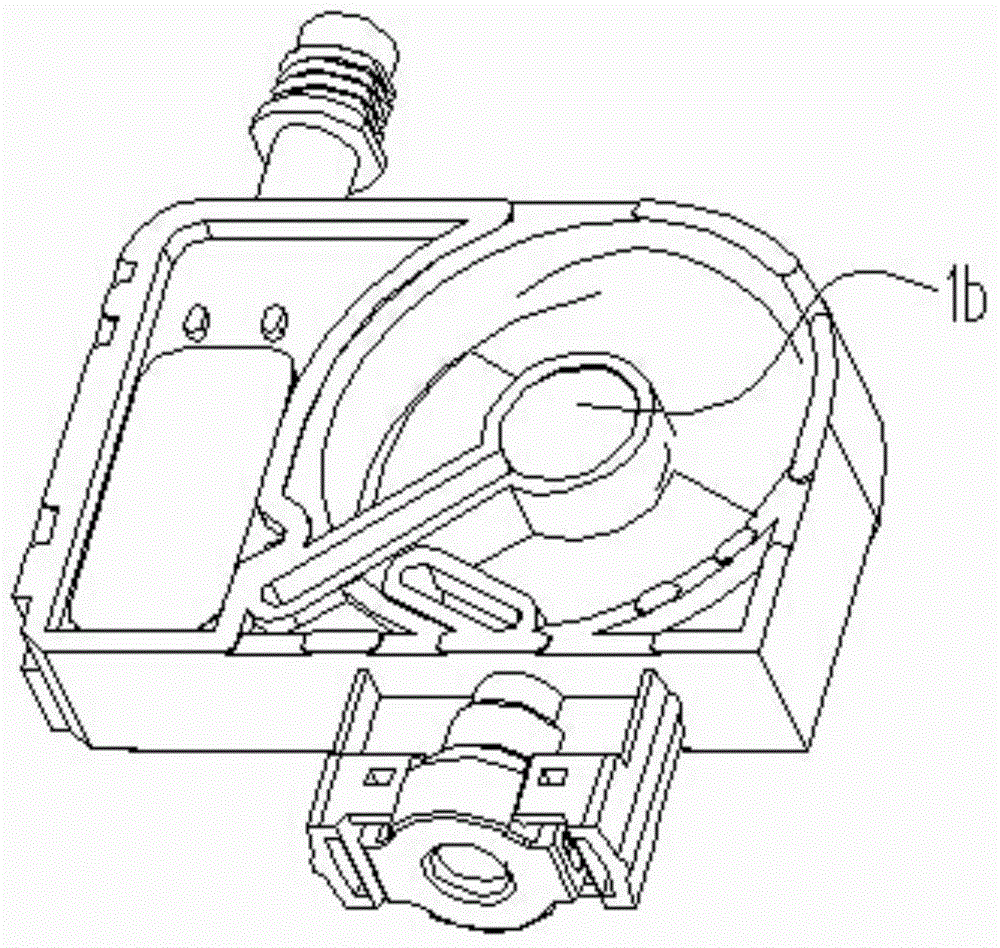

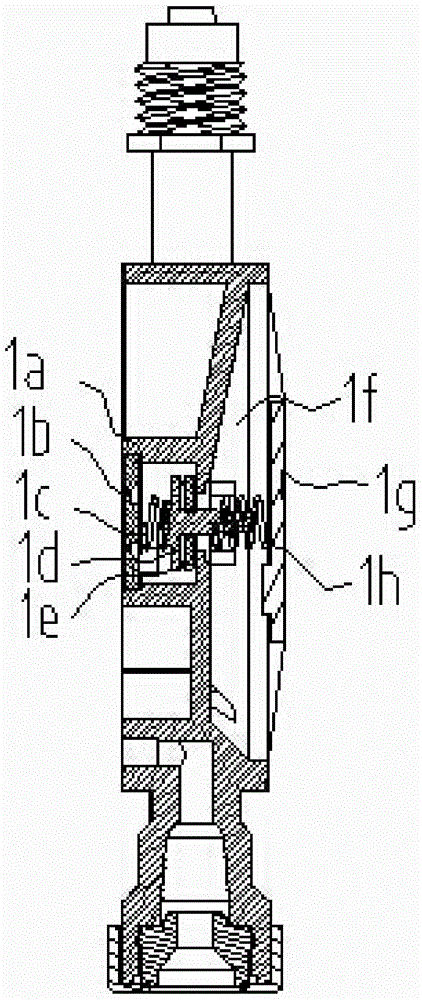

[0053] refer to Figure 4-7 : large-capacity exhaust ink bag 2 for large-format printers, including ink bag main body 2a, small plastic disc 2b, first spring 2c, plastic boss 2d, rubber seal 2e, large plastic disc 2g, second spring 2h, Exhaust port 2i and film buffer chamber 2f (preferably adopting large-capacity film buffer chamber 2f, the inner diameter of the ink bag film buffer chamber is 33 mm, and the height is 5.5 mm). What ink sac vent end is connected is an end of PVC pipe 3, and the other end of PVC pipe 3 is sealed with supporting plastic plug 4.

[0054] The PVC pipe 3 and the ink bag exhaust port 2i are connected together with special sealing glue to ensure that the PVC pipe is closely connected with the exhaust port and is not easy to fall off.

[0055] The plastic plug 4 can be closely matched with the other end of the PVC pipe 3, which can ensure that the PVC pipe is completely isolated from the outside world and that the ink bag will not leak.

[0056] The u...

Embodiment 1

[0060] The ink bag provided by embodiment one (the film buffer chamber 2f adopted, the inner diameter of the ink bag film buffer chamber is 33 millimeters, and the height is 5.5 millimeters) is better than the supporting ink bag (diameter of the ink bag) of EPSON 5th generation micro piezoelectric nozzles on the market. At 29 mm, the height of the chamber is 3.5 mm), which doubles the capacity of the film buffer chamber, but the continuous printing time of the printer has increased by at least 2.5 times, effectively improving the printing efficiency and printing quality.

Embodiment 2

[0062] The difference between this embodiment and embodiment 1 is that the ink bag has 2 channels, that is, one ink bag integrates the 2 ink bags of embodiment 1, and there are also 2 exhaust pipes correspondingly. The top of the exhaust pipe is provided with a clip for sealing the exhaust pipe, and two large-capacity film buffer chambers, the working principle and operation method of which are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com