Door carving process

A processing technology and door body technology, which is applied in wood processing appliances, metal processing equipment, processes for producing decorative surface effects, etc. problem, to achieve the effect of improving production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: The specific steps of the door engraving process are as follows:

[0017] (1) Base material treatment: As the base material of the door body to be inlaid, wood or wood-based panels with better processing performance can be selected. Has a slot.

[0018] (2) Substrate processing: According to the design, place one or more plastic carving models at the corresponding positions, and fix the plastic carving models on the door panel with steel nails. The carving models can also be fixed on the substrate in other ways. Use an electric watering can to evenly spray the white latex on the base material and the plastic carved model. The spray thickness is 0.1mm-0.4mm, and 0.2mm-0.3mm is the best.

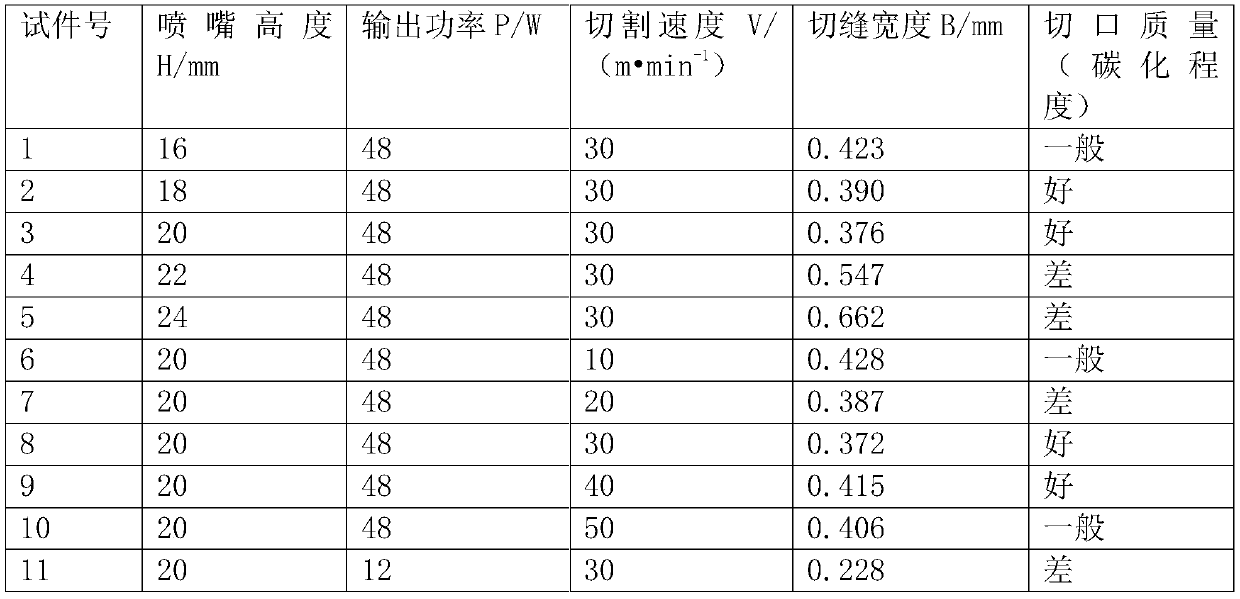

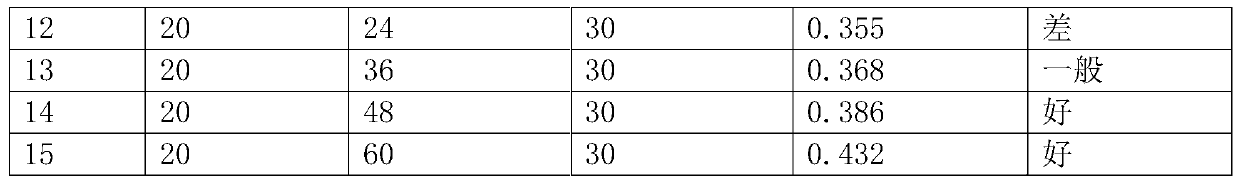

[0019] (3) Bamboo veneer cutting: According to the requirements, import the plastic carved sample model into the special software of the cutting machine, and then control the cutting machine to cut and process the bamboo veneer. The cutting parameters need to be adjusted ...

Embodiment 2

[0024] Embodiment 2: The specific steps of the door body engraving process are as follows:

[0025] This embodiment 2 is aimed at the thin bamboo veneer below 0.5mm. In the cutting of bamboo veneer, the cutting machine adopts the processing parameters of nozzle height of 20mm, speed of 20-40m / min, and laser output power of 48W. The processing parameters After many experiments, it was found that the number of repetitions is small and the width of the incision is less than 0.4mm, and the incision is basically free from carbonization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com