High-precision lens press-in assembling device

An assembly device and high-precision technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of complex program setting, high equipment investment, and large precision deviation, and achieve simple and fast coaxial positioning, reducing the initial The effect of input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

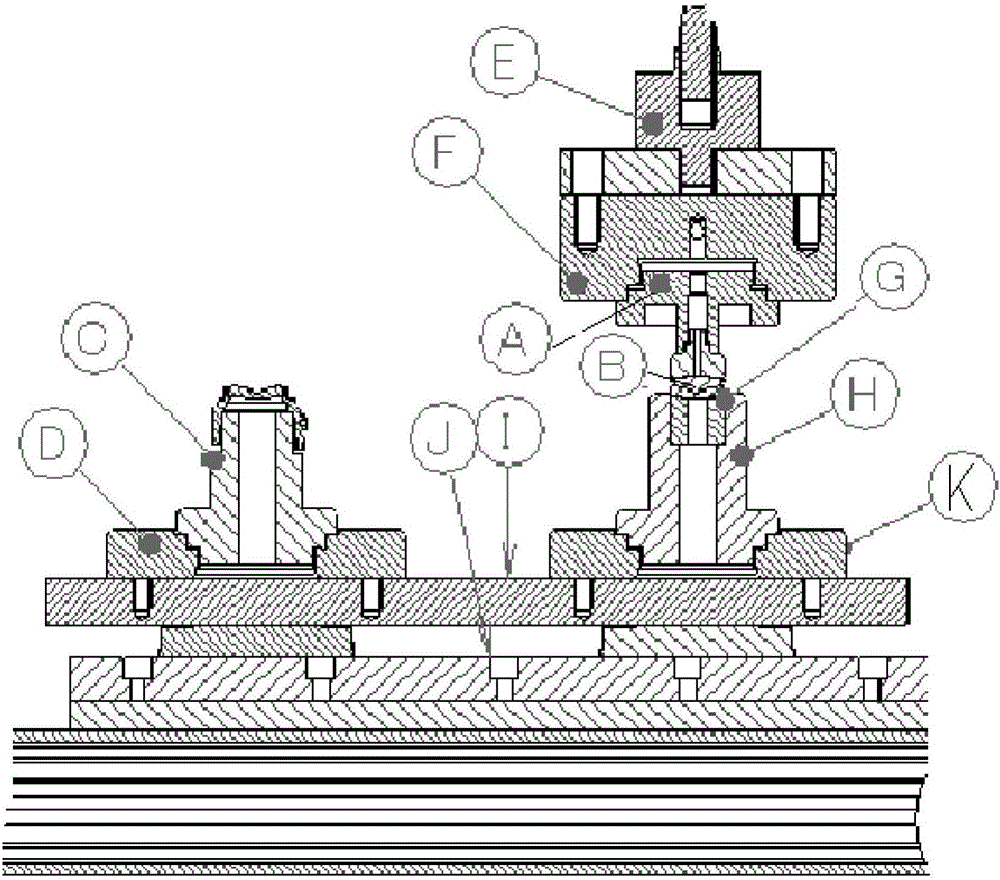

[0019] figure 1 It is a structural schematic diagram of a high-precision lens press-fit assembly device according to an embodiment of the present invention. As shown in the figure, the high-precision lens press-in assembly device includes a lens barrel seat C, a lens seat G, a lens press-in mechanism and a sliding mechanism I. The device is placed on a workbench J as a whole, and the sliding mechanism I can work Slide left and right on the platform J, and the left and right sides of the sliding mechanism I fix the lens barrel seat C and the lens seat G respectively. In this embodiment, the lens barrel seat C is fixed on the sliding mechanism I through the lens barrel seat fixing table D, and the lens seat G is fixed on the sliding mechanism I through the lens seat sleeve H. G is in clearance fit with the lens holder sleeve H so that the lens holder G can rotate in the lens holder sleeve H so that the direction of the lens holder G can be adjusted. The lens pressing mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com